Water transfer printing process

A water transfer printing and process technology, applied in the printing field, can solve the problems of not too delicate, easy to fall off, damaged, uneven, etc., and achieve the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

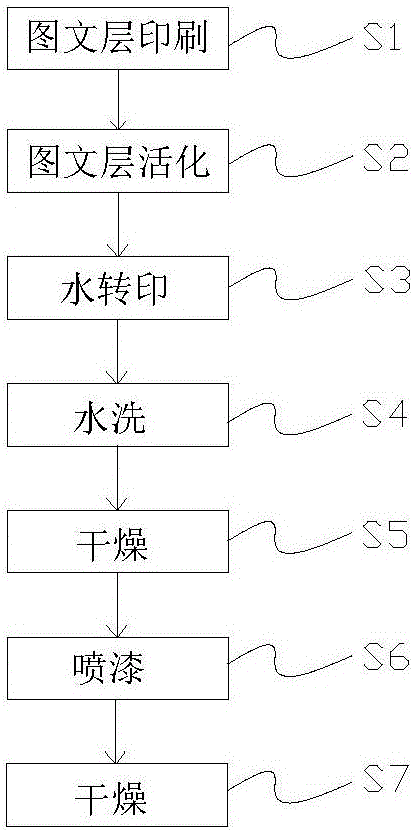

[0033] S1: graphic layer printing, including: a. setting a graphic layer on the first side of the PET film; b. setting a layer of PVA film on the graphic layer on the first side of the PET film; c. tearing off the The PET film;

[0034] Further, in step a, before printing the graphic layer on the first side of the PET film, a layer of release layer is first coated on the first side of the PET film, the release layer is a kind of resin, and the The graphic layer is arranged on the release layer, and the graphic layer is a printed ink layer or an electroplated metal layer. The printing of the ink layer adopts screen printing or gravure printing, and the ink used for printing is UV ink; In a specific embodiment, before printing or electroplating the graphic layer, a metal layer may be vapor-deposited on the first side of the PET film, and then the graphic layer may be printed or electroplated on the metal layer;

[0035] Further, in step b, a layer of PVA film is provided on the...

Embodiment 2

[0043] S1: graphic layer printing, including: a. setting a graphic layer on the first side of the PET film; b. setting a layer of PVA film on the graphic layer on the first side of the PET film; c. tearing off the The PET film;

[0044] Further, in step a, the graphic layer is printed on the PET film by screen printing or gravure printing, and before the graphic layer is printed on the first side of the PET film, a Layer release layer, the release layer is a kind of resin, the graphic layer is arranged on the release layer, the graphic layer is a printed ink layer or an electroplated metal layer, and the ink used for printing is UV ink In another specific embodiment, it is also possible to vapor-deposit a metal layer on the first side of the PET film before printing or electroplating the graphic layer, and then print or electroplate the graphic layer on the metal layer;

[0045] Further, in step b, a layer of PVA film is provided on the graphic layer on the first side of the ...

Embodiment 3

[0053] S1: graphic layer printing, including: a. setting a graphic layer on the first side of the PET film; b. setting a layer of PVA film on the graphic layer on the first side of the PET film; c. tearing off the The PET film;

[0054] Further, in step a, the graphic layer is printed on the PET film by screen printing or gravure printing, and before the graphic layer is printed on the first side of the PET film, a Layer release layer, the release layer is a kind of resin, the graphic layer is arranged on the release layer, the graphic layer is a printed ink layer or an electroplated metal layer, and the ink used for printing is UV ink In another specific embodiment, it is also possible to vapor-deposit a metal layer on the first side of the PET film before printing or electroplating the graphic layer, and then print or electroplate the graphic layer on the metal layer;

[0055] Further, in step b, a layer of PVA film is provided on the graphic layer on the first side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com