Meshing teeth-shaped anti-aging lateral stabling rod liner bushing

A technology for a lateral stabilizer bar and a stabilizer bar bushing, which is applied in the field of auto parts, can solve the problems of reducing service life and wear of the stabilizer bar bushing, etc., and achieves the effects of improving service life, ensuring quality, and improving axial stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

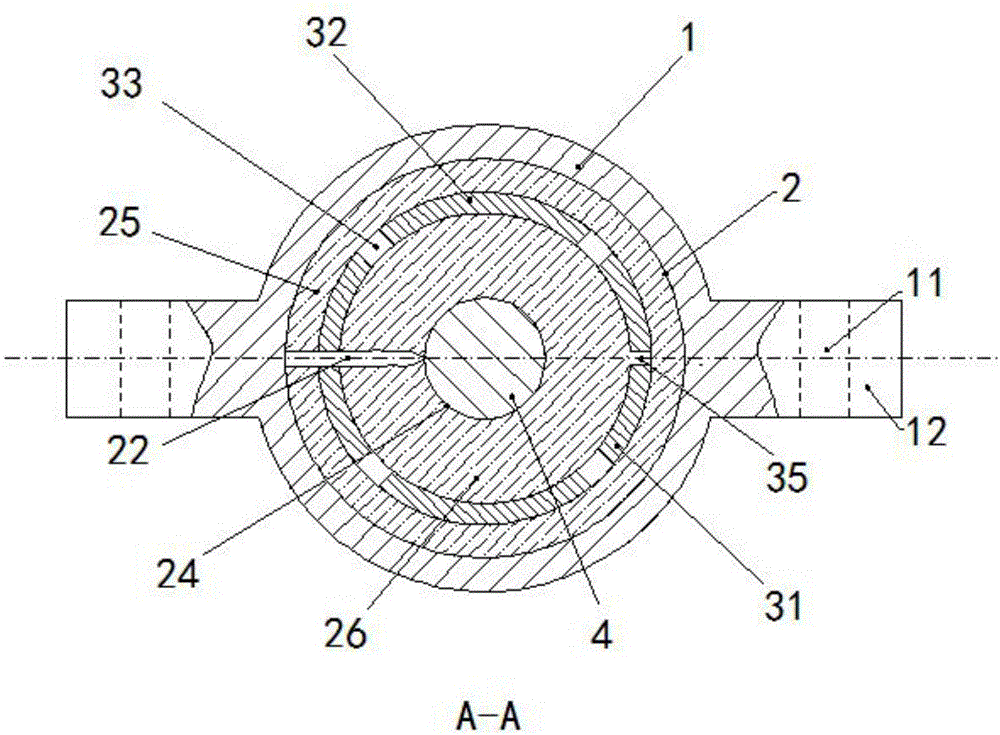

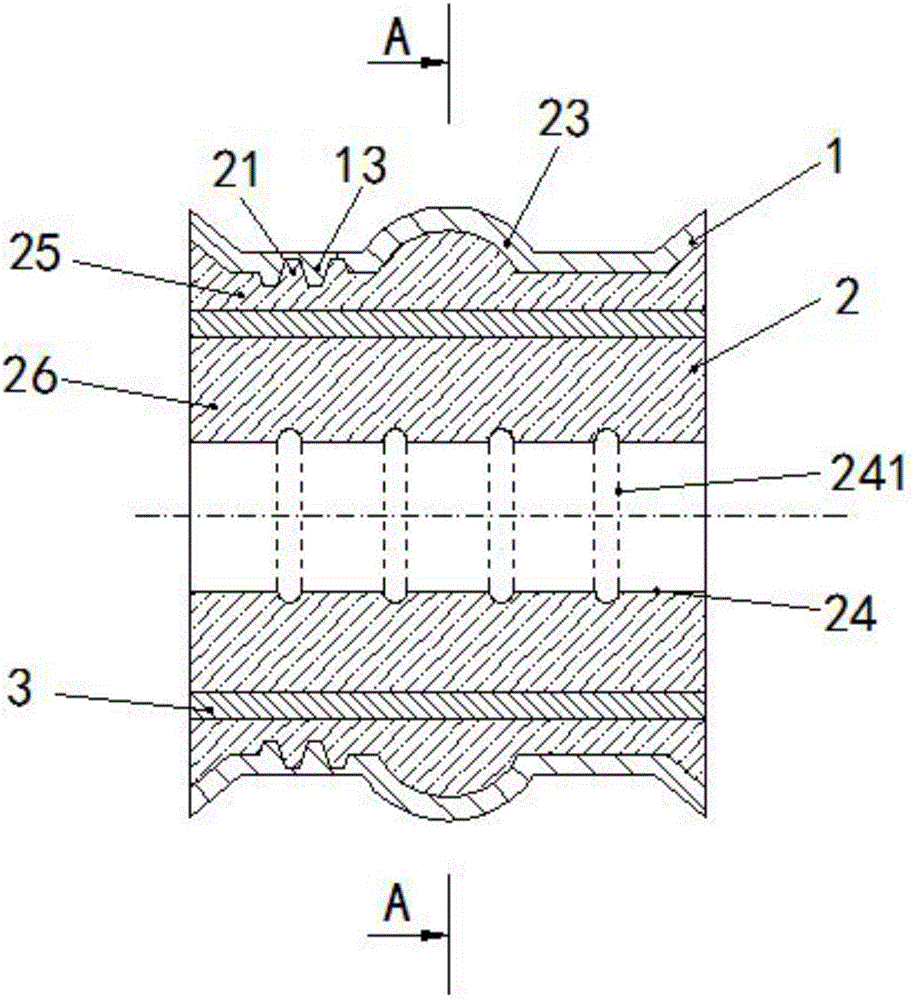

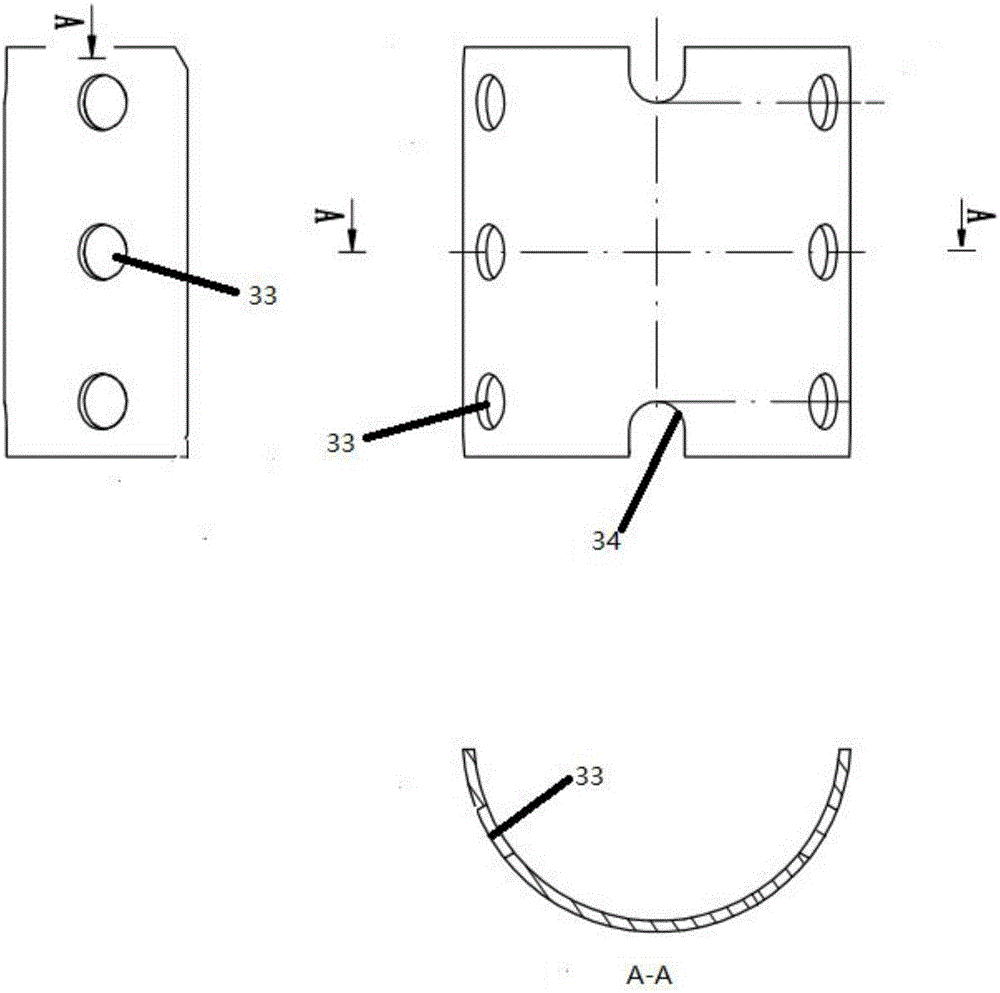

[0038] A rod-shaped anti-aging stabilizer bar bushing, including a fixed bracket 1, a bushing body 2 and a skeleton 3;

[0039]As shown in the drawings, a bushing rib 23 is provided in the middle of the surface of the bushing body 2, and a bushing meshing tooth 21 is arranged between the edge of the bushing body 2 and the rib 23, and the side of the bushing body 2 is provided with There is a slit 22 perpendicular to the stabilizer bar 4, the slit 22 is cut from the outer surface of the bushing body to the inner hole 24 of the bushing; an annular groove 241 is uniformly arranged on the inner hole wall of the bushing, and the bushing The main body 2 is embedded with a skeleton 3, and the skeleton 3 divides the bushing body 2 into two parts, an outer rubber layer 25 and an inner rubber layer 26, and the thickness of the inner rubber laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com