Wood chip conveying device

A conveying device and wood chip technology, applied in the directions of transportation, packaging, conveyors, etc., can solve the problems of inability to automatically unload wood chips, poor consistency, and poor intelligence, and achieve the effects of simple structure, high automation strength, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

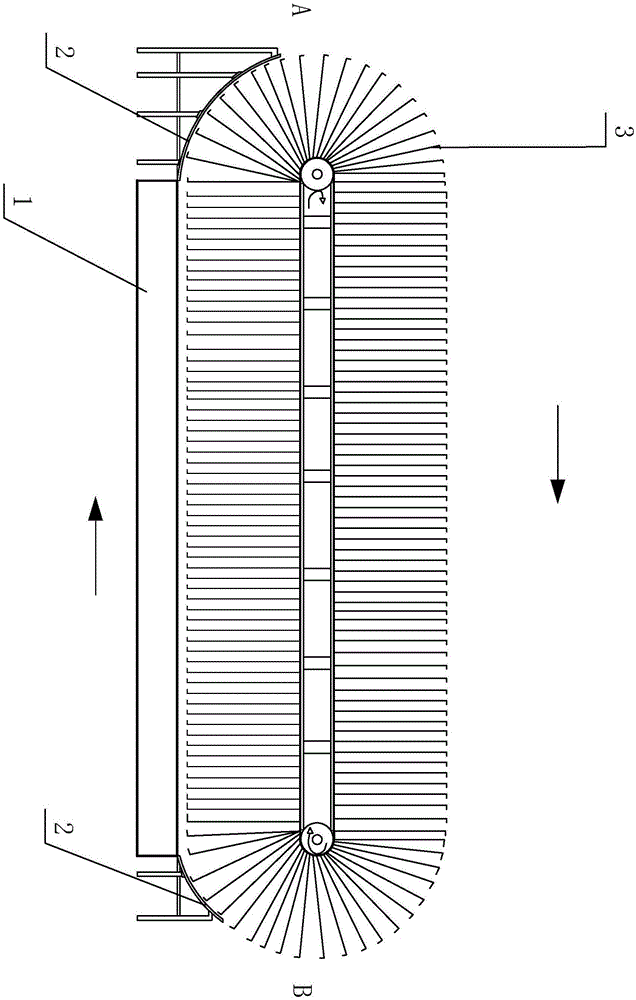

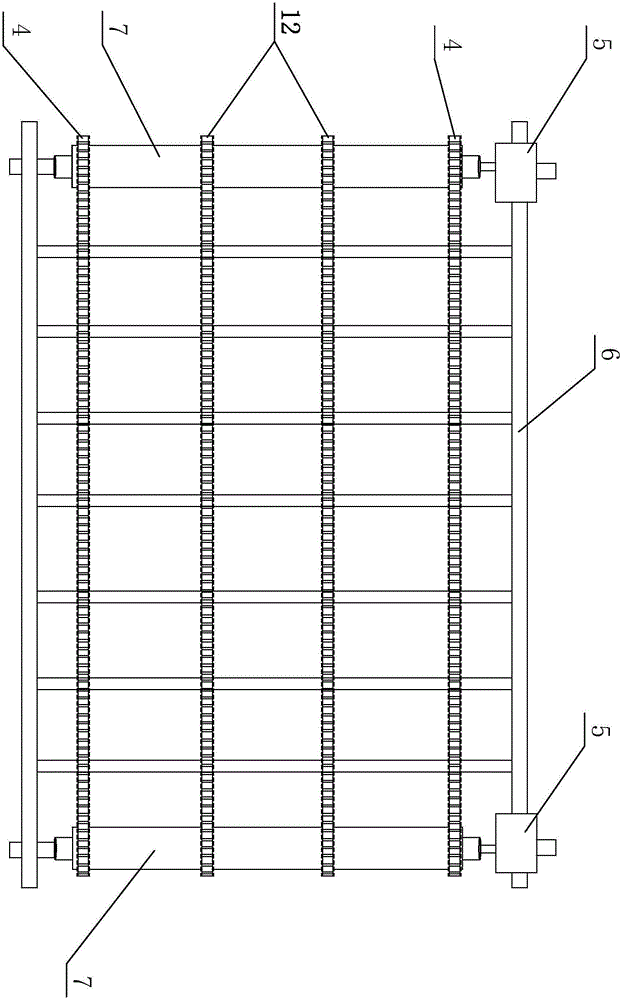

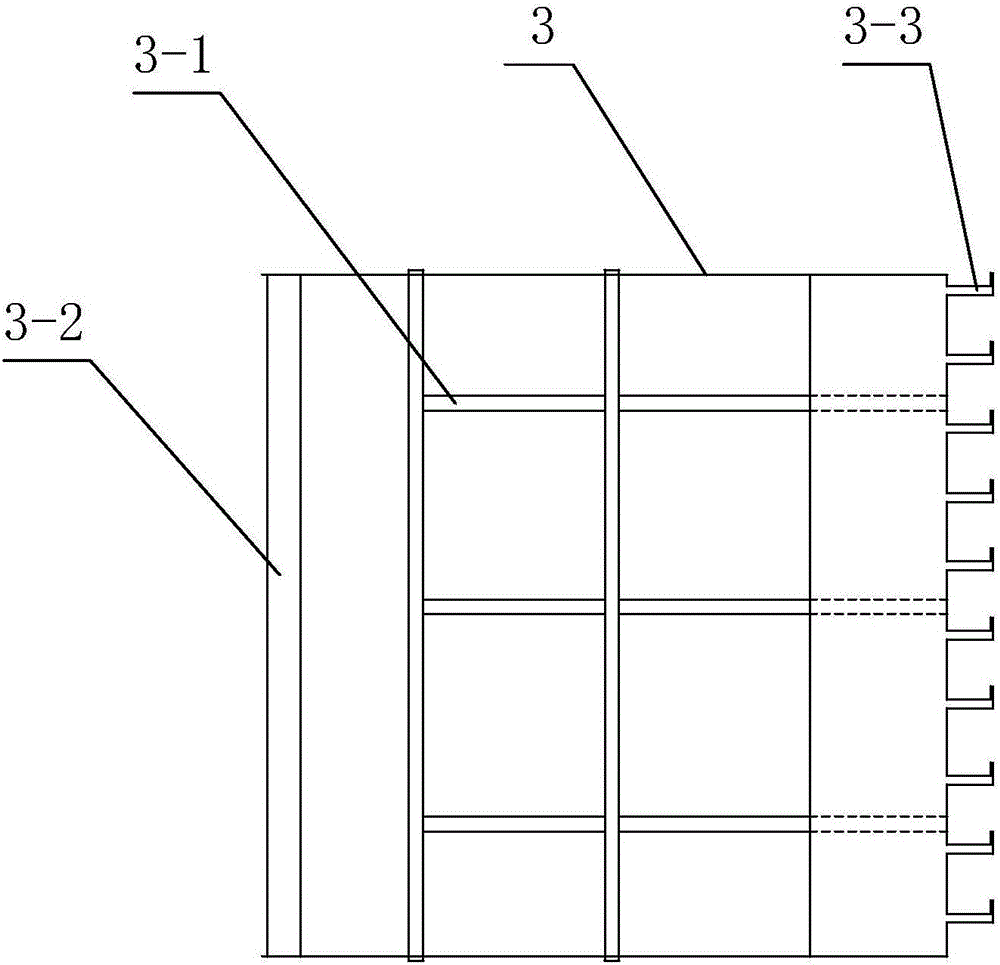

[0024] Such as figure 1 , figure 2 , Figure 7 As shown, a kind of chip conveying device comprises base 1 and transmission mechanism, and described transmission mechanism is installed on the top of base 1 through support 6, and described transmission mechanism comprises a pair of drive shafts 7 that are installed in parallel on support 6 two ends and is used for The driving device 5 that drives the transmission shaft 7 to work. The driving device 5 is specifically a variable speed motor. In this embodiment, there are specifically two driving devices 5 , that is, one transmission shaft 7 is correspondingly driven by one driving device 5 . In order to intelligently control the work of the wood chip conveying device, a controller is connected to the driving device 5 . The two ends of the pair of transmission shafts 7 are respectively connected with chains 4 , and below the chains 4 , rails 10 for sliding the chains 4 are installed on the bracket 6 . Mounting disks 3 for load...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap