Environment-friendly pig raising method

An environment-friendly, pig farm technology, applied in the field of pig raising, can solve the problems of high water content of the mixture, less effective ingredients, low efficiency, etc., and achieve the effect of environmental protection and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

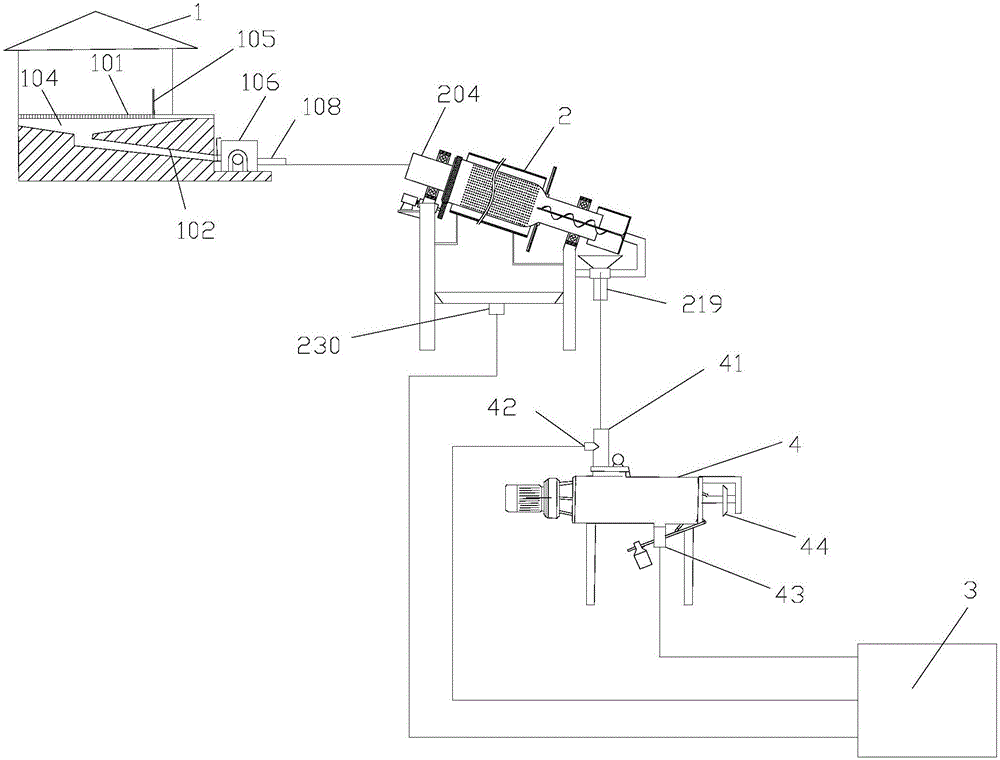

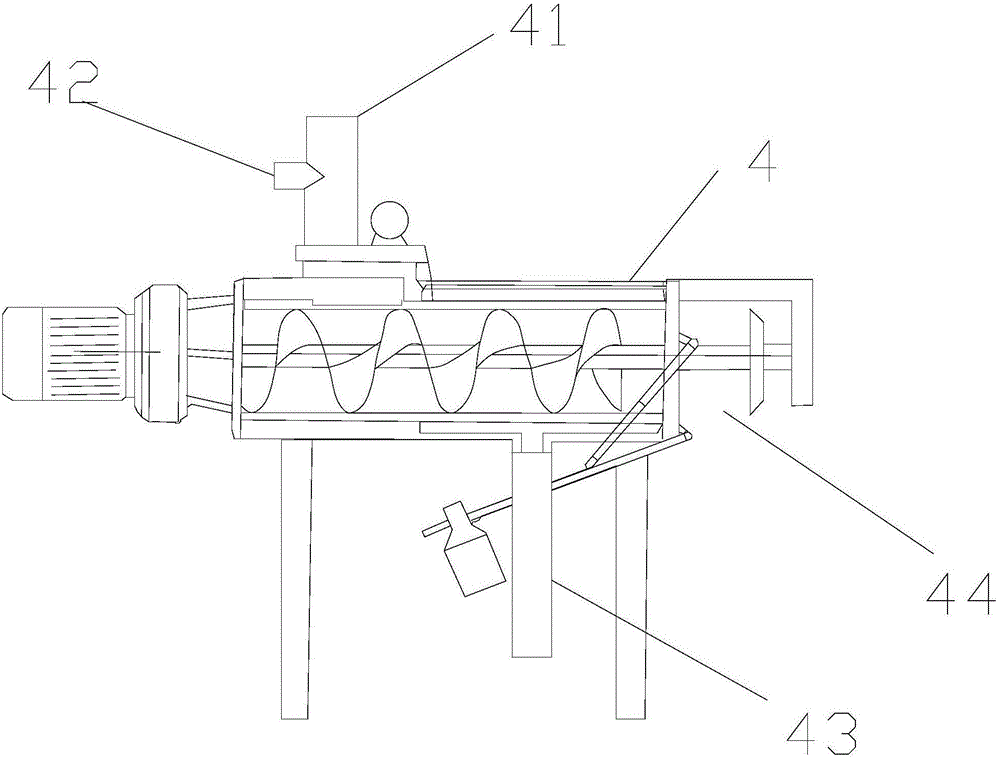

[0025] Such as figure 1 As shown, the environment-friendly pig raising method described in this embodiment adopts a pig house 1 and a biogas digester 3 in a pig farm. The feature is that the pig manure produced during the breeding process is first collected in the manure tank 106, from The excrement discharged from the manure tank 106 enters the centrifugal pre-separation device 2. In the centrifugal pre-separation device 2, part of the manure water is separated and discharged into the biogas tank 3, and the excrement discharged from the centrifugal pre-separation device 2 enters The livestock manure solid-liquid separator 4 performs separation, and the manure water discharged from the overflow port 42 and the liquid outlet 43 of the livestock manure solid-liquid separator 4 is discharged into the biogas digester 3, and from the solid outlet of the livestock manure solid-liquid separator 4 44 The solid feces discharged are used for sale.

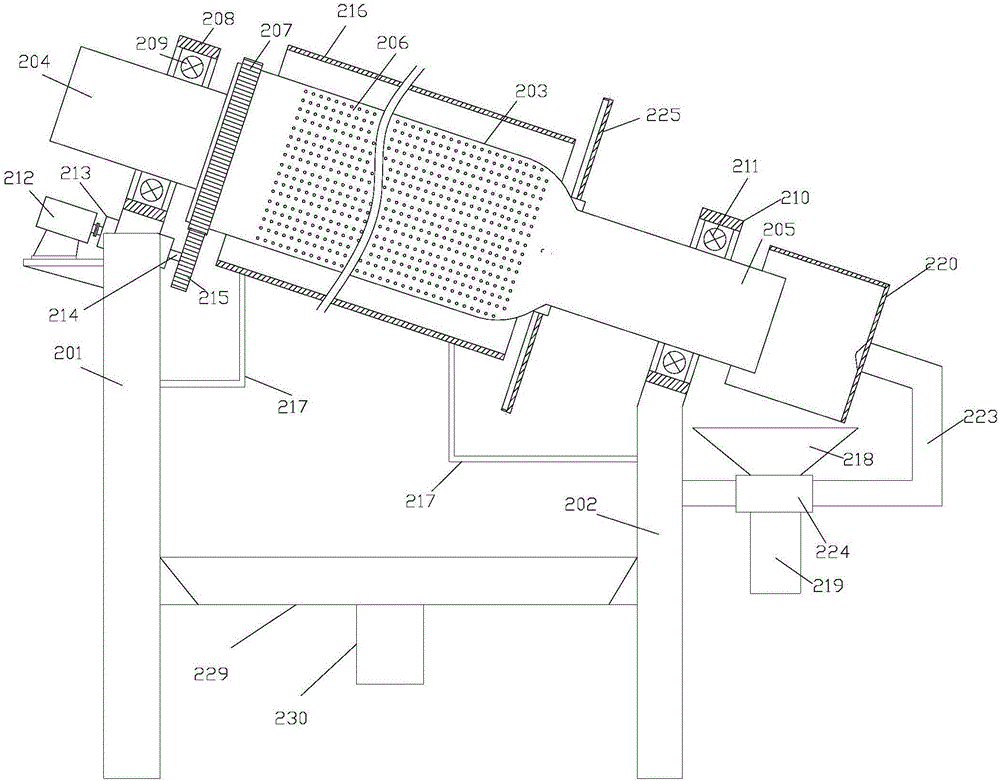

[0026] Specifically: such as Figure 4 w...

Embodiment 2

[0039] The environment-friendly pig raising method described in this embodiment differs from embodiment 1 in that a liquid level switch is provided on the overflow port 42 of the livestock manure solid-liquid separator 4, and when the liquid level switch detects When it overflows, stop the extrusion motor 113 and the centrifugal separation motor 212,

[0040] Or instead of stopping the motor, the extrusion motor 113 and the centrifugal separation motor 212 are decelerated to operate.

[0041] When the squeezing motor 113 stops or decelerates, the excrement tank 106 is discharged into the centrifugal pre-separation device 2 to stop or slow down

[0042] When the centrifugal separation motor 212 stops or decelerates, the centrifugal pre-separation device 2 will stop or decelerate.

[0043] In this way, when the livestock manure solid-liquid separator 4 cannot handle the overflow, the two devices above the manure tank 106 and the centrifugal separation motor 212 are stopped or decelerate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com