Flame-retardant light-stabilized polycarbonate and preparation method thereof

A polycarbonate and light-stabilized technology, which is applied in the field of plastic processing, can solve the problems of mechanical property degradation and product yellowing, and achieve the effects of optimizing flame retardancy, promoting adhesion, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

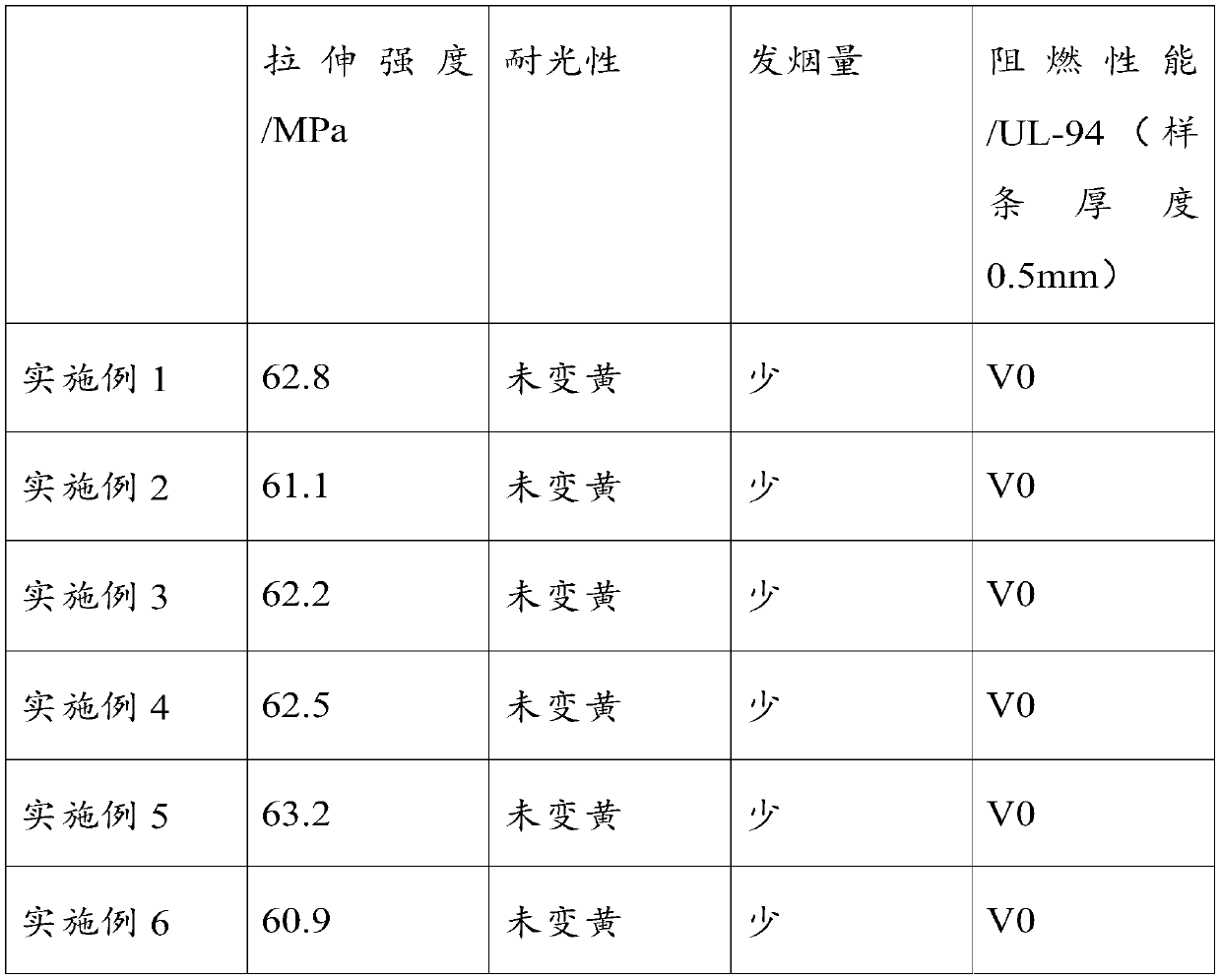

Examples

preparation example Construction

[0026] The preparation method of above-mentioned flame-retardant light stable polycarbonate, it comprises the following steps:

[0027] Add polycarbonate, composite flame retardant, light stabilizer, composite antioxidant, lubricant and dispersant into a high-speed mixer and mix thoroughly for 15 to 30 minutes to form a material;

[0028] The material is fed into a twin-screw extruder for melting and mixing, and then extruded, cooled, granulated, and dried.

Embodiment 1

[0031] Prepare raw materials according to the raw material formula, including polycarbonate 84%, composite flame retardant 6%, light stabilizer 8%, composite antioxidant 0.4%, paraffin 0.8%, polyvinylpyrrolidone and oleic acid according to mass percentage 0.8% of the mixture; the composite flame retardant contains expandable graphite, nano-carbonyl iron powder, zinc borate, graphene and silane coupling agent in a weight ratio of 20:5:20:4:15, and the nano-carbonyl iron powder The diameter is 20nm, and the light stabilizer contains zinc oxide, benzophenone ultraviolet absorber and bis(3,5-di-tert-butyl-4-hydroxybenzylphosphonic acid monoethyl ester) nickel; the compound antioxidant contains 2,6-di-tert-butyl-4-methylphenol and trioctyl phosphite in a weight ratio of 1:1. Add the raw materials prepared above into a high-speed mixer and mix them thoroughly for 30 minutes to form a material; put the material into a twin-screw extruder for melting and mixing, then extrude, cool, gr...

Embodiment 2

[0033] Prepare raw materials according to the raw material formula, including 90% polycarbonate, 6.8% composite flame retardant, 2% light stabilizer, 0.5% composite antioxidant, 0.2% paraffin, polyvinylpyrrolidone and oleic acid according to mass percentage 0.8% of the mixture; the composite flame retardant contains expandable graphite, nano-carbonyl iron powder, zinc borate, graphene and silane coupling agent in a weight ratio of 30:10:30:3:30, and the nano-carbonyl iron powder The diameter is 80nm, and the light stabilizer contains zinc oxide, benzophenone ultraviolet absorber and bis(3,5-di-tert-butyl-4-hydroxybenzylphosphonic acid monoethyl ester) nickel; the compound antioxidant contains 2,6-di-tert-butyl-4-methylphenol and bis(3,5-di-tert-butyl-4-hydroxyphenyl)sulfur in a weight ratio of 1:1 Ether mixtures and trioctyl phosphite. Add the raw materials prepared above into a high-speed mixer and mix them thoroughly for 27 minutes to form a material; put the material into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com