Preparation method of high-decoration elevator panel coating

A decorative, elevator technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as unsatisfactory and increased manufacturing costs, achieve high gloss and fullness, excellent decorative properties, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

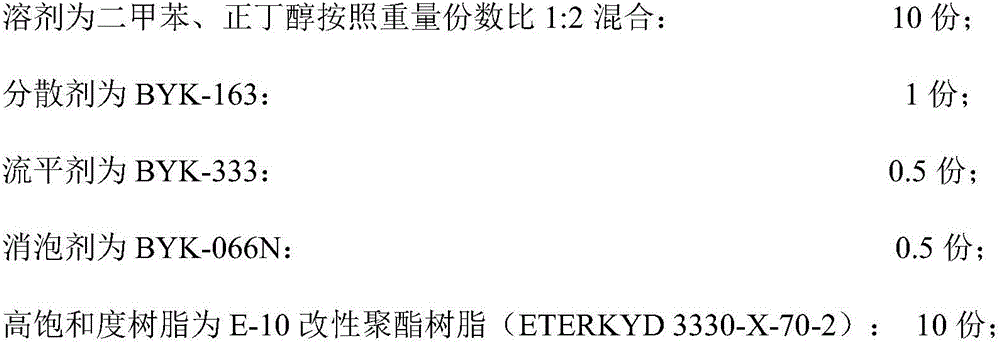

Embodiment 1

[0024] A kind of highly decorative elevator trim coating is prepared by the raw materials comprising following parts by weight:

[0025]

[0026]

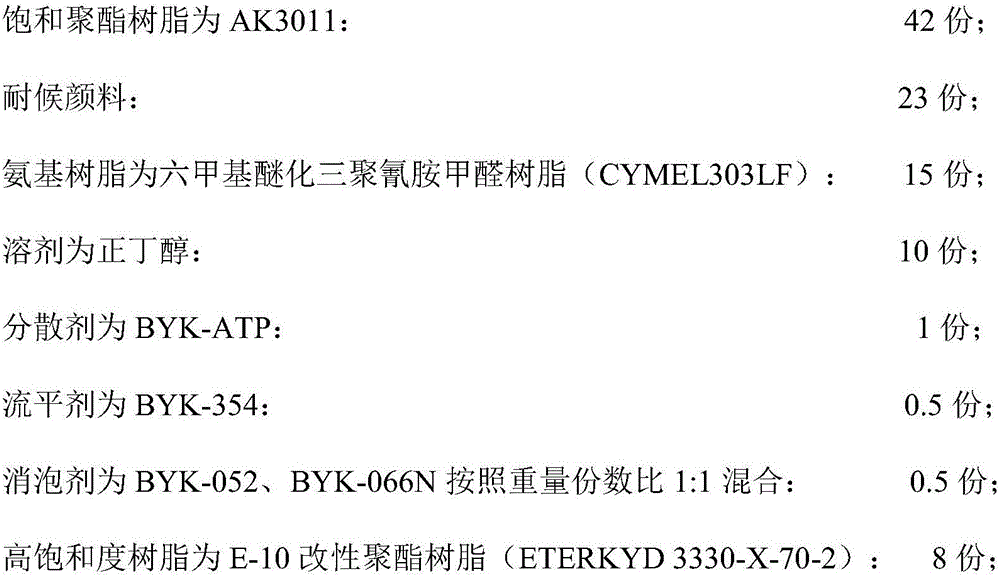

Embodiment 2

[0028] A kind of highly decorative elevator trim coating is prepared by the raw materials comprising following parts by weight:

[0029]

Embodiment 3

[0031] A kind of highly decorative elevator trim coating is prepared by the raw materials comprising following parts by weight:

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com