Three-dimensional papermaking felt and making method thereof

A papermaking felt, three-dimensional technology, applied in the field of three-dimensional papermaking felt and its preparation, to achieve the effects of uniform dehydration, increased structural stability, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

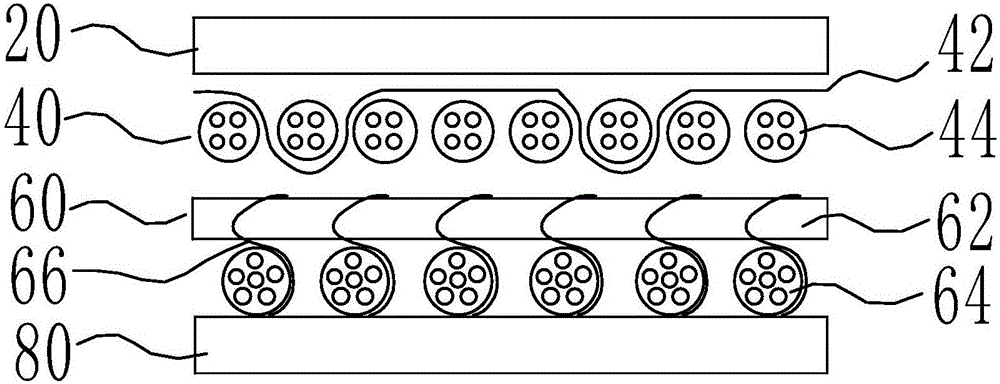

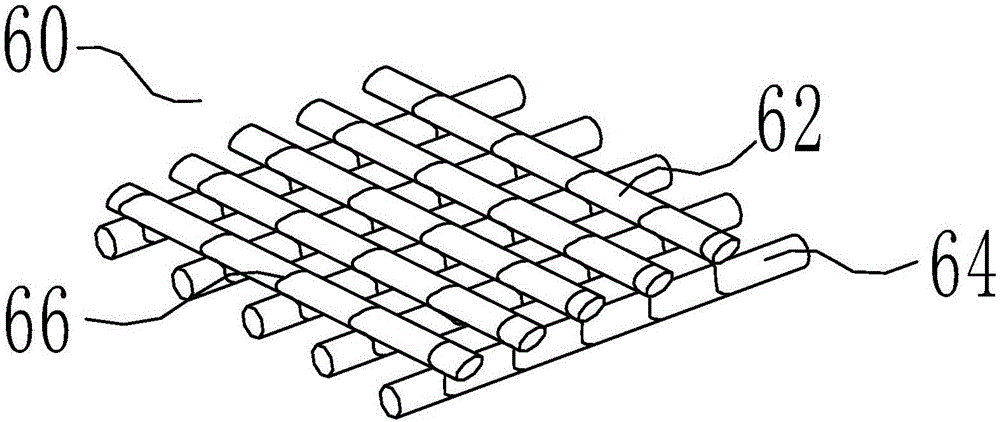

[0028] refer to figure 1 as well as figure 2 , figure 1 It is a structural schematic diagram of the first embodiment of the three-dimensional papermaking felt of the present invention, figure 2 It is a structural schematic diagram of the lower base fabric layer of the first embodiment of the three-dimensional papermaking felt of the present invention, and this embodiment includes:

[0029] Surface flocking layer 20, upper base fabric layer 40, lower base fabric layer 60 and reverse flocking layer 80;

[0030] Wherein, the lower base fabric layer 60 includes a warp thread sub-layer 62 and a weft thread sub-layer 64 stacked up and down, and the warp thread sub-layer 62 and the weft thread sub-layer 64 are fixed by binding threads 66 to form the lower base fabric layer 60 .

[0031] In this embodiment, the three-dimensional papermaking felt is fixed into a whole by binding threads 66 by setting the warp sub-layers 62 and weft sub-layers 64 of the lower base fabric layer 60 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com