Glass fiber mat for gypsum board caulking and preparing method thereof

A glass fiber mat and glass fiber technology, which is applied in the field of glass fiber mat for caulking of gypsum board and its preparation field, can solve the problems of poor corrosion resistance and crack resistance, difficult to completely fill the paint, affecting the decoration effect, etc. To achieve the effect of convenient coating and processing, friendly interface and excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

[0025] The preparation method of glass fiber felt for caulking of gypsum board is as follows:

[0026] 1. Slurry preparation:

[0027] First, add a certain volume of pure water to the mixing tank and slurry tank. In order to ensure that the glass fiber chopped strands can be dispersed, a certain amount of thickener, dispersant, defoamer, etc. should be added to the pure water. The auxiliary agent is formulated into white water with a viscosity of 7.0CP.

[0028] After the preparation of white water is completed, glass fibers with a diameter of 13 microns and a length of 18 millimeters and two kinds of glass fibers with a diameter of 18 microns and a length of 36 mm are added to the feed bin, weighed by a belt scale and put into white water in proportion to stir evenly to obtain Slurry, the concentration of glass fiber chopped strands in the slurry is about 0.14%. Wherein, the ratio of long fiber and short fiber is 1:1.

[0029] 2. Dehydration molding:

...

Example Embodiment

[0042] Example 2

[0043] The difference between the preparation method of this kind of gypsum board caulking glass fiber thin felt and embodiment 1 is:

[0044] Two specifications of glass fiber chopped strands were selected, with diameters of 6 microns and 13 microns and lengths of 6 mm and 30 mm respectively, and the weight ratio of the two was 3:1.

[0045] The slurry concentration of the glass fiber in the slurry preparation section is 0.11%, and the viscosity of the prepared white water is 6.2CP.

[0046] The dehydration flows in the first to fifth zones of the dehydration molding section are: 310m 3 , 330m 3 , 1100m 3 , 800m 3 and 270m 3 .

[0047] The mass percentage of urea-formaldehyde resin, acrylate, coupling agent and color paste in the binder is 72:25:2:1. The concentration of the binder emulsion configured in the wet felt dipping process is 30%.

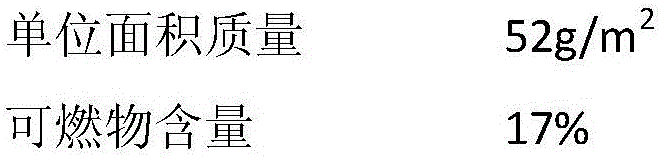

[0048] The technical performance index of the glass fiber thin felt of gained under this method is as follow...

Example Embodiment

[0050] Example 3

[0051]The difference between the preparation method of this kind of gypsum board caulking glass fiber thin felt and embodiment 1 is:

[0052] Chopped glass fibers of three specifications are selected, with diameters of 10 microns, 13 microns, and 13 microns, and lengths of 12 mm, 12 mm, and 36 mm, respectively, and the weight ratio of the three is 1:1:1.

[0053] The slurry concentration of the glass fiber in the slurry preparation section is 0.15%, and the viscosity of the prepared white water is 7.8CP.

[0054] The dehydration flows in the first to fifth zones of the dehydration molding section are: 470m 3 , 480m 3 , 1000m 3 , 600m 3 and 100m 3 .

[0055] The mass percent of urea-formaldehyde resin, acrylate, coupling agent and color paste in the binder is 80:15:4.5:0.5. The concentration of the binder emulsion configured in the wet felt dipping process is 15%.

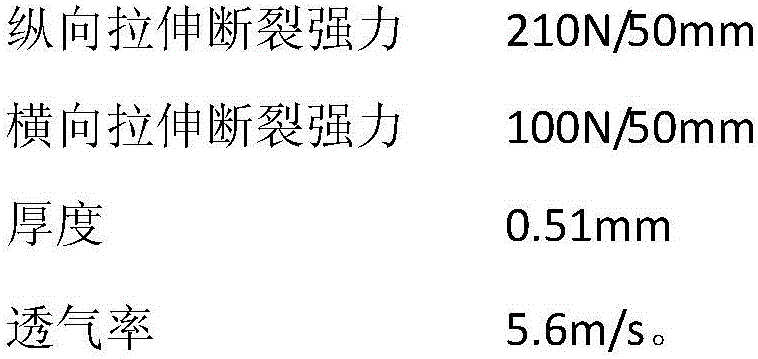

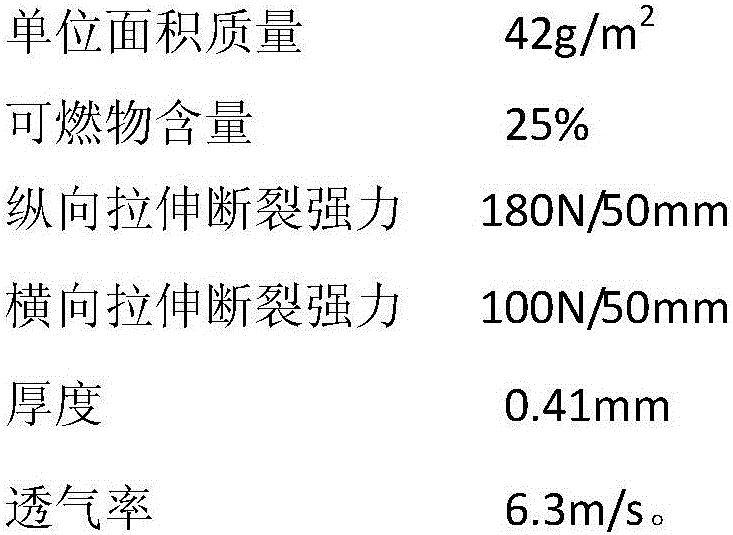

[0056] The technical performance index of the glass fiber thin felt of gained under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap