Electrical type balance oil cylinder potential energy recycling system

A technology of balancing oil cylinders and recovering potential energy, which is applied to earth movers/shovels, construction, etc., and can solve the problem of the difficulty in directly releasing the pressure of the hydraulic accumulator, affecting the controllability of the actuator, and the pressure difference change of the actuator speed control valve, etc. problem, to achieve the effect of reducing energy consumption, maintaining the controllability, and reducing power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

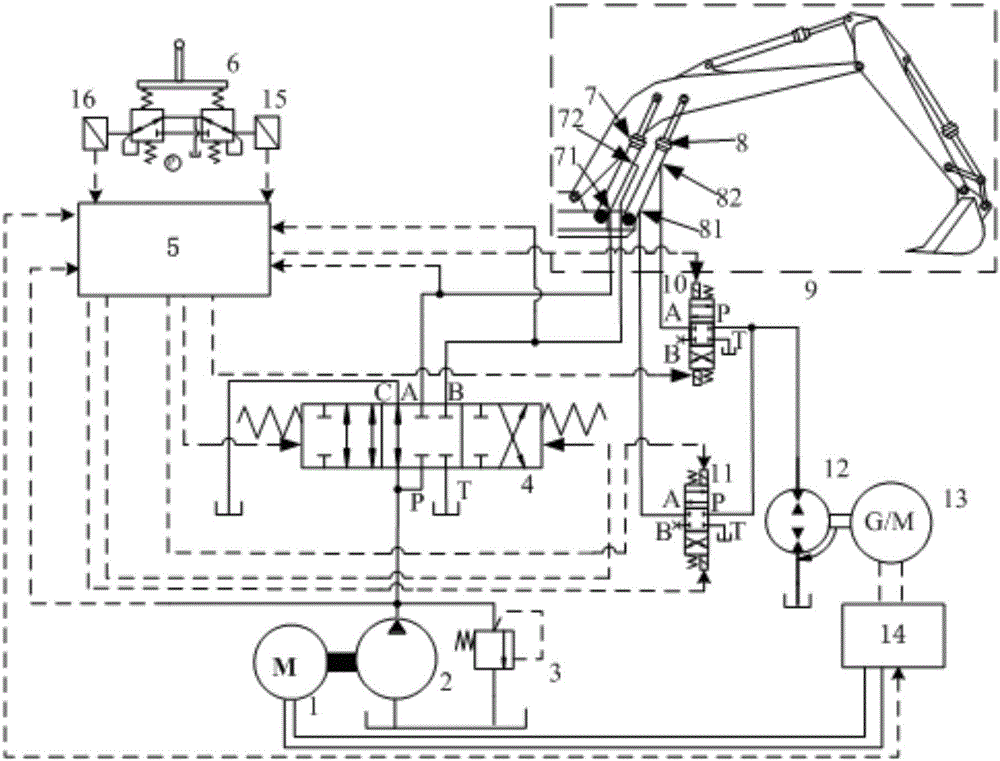

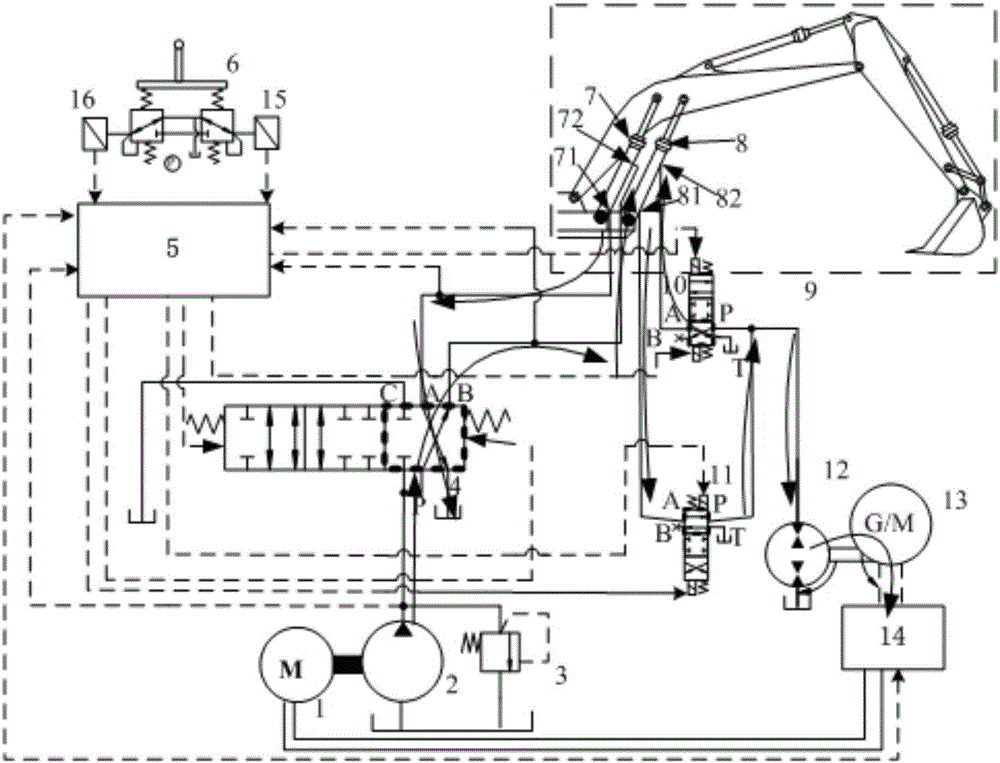

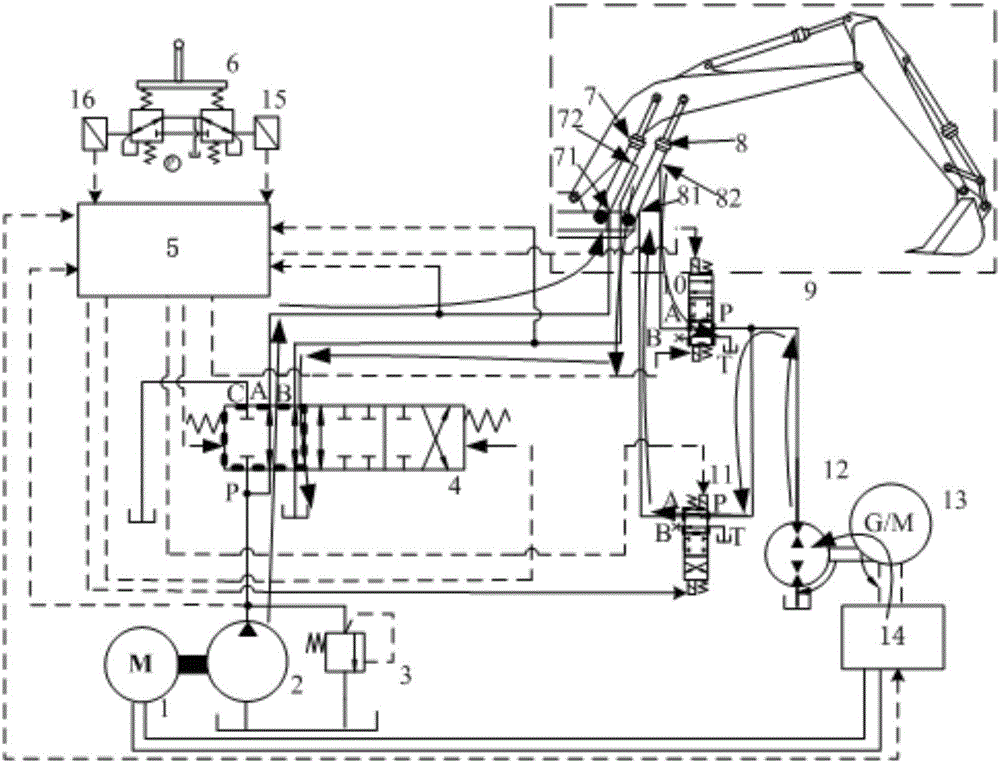

[0028] see figure 1 As shown, an electric balance cylinder 8 potential energy recovery system of the present invention includes a driving motor 1, a hydraulic pump 2 and an original driving cylinder 7, and the original driving cylinder 7 is attached to a boom device 9 of a construction machine. The drive cylinder 7 has a rod chamber 72 and a rodless chamber 71;

[0029] It also includes a balance oil cylinder 8, a controller 5, a two-way hydraulic pump / motor 12, an electric / generator 13 and a power battery 14, the balance oil cylinder 8 is attached to the boom device 9, and the balance oil cylinder 8 is connected to the There is a certain interval between the original driving cylinders 7, and they are arranged symmetrically on both sides of the boom device 9; The power battery 14 is electrically connected; the balance cylinder 8 includes a rod chamber 82 and a rodless chamber 81, the rod chamber 82 of the balance cylinder 8 is connected with the first reversing valve 10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com