External wall cleaning machine

An exterior wall cleaning machine and cleaning disk technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of inflexible cleaning of cleaning robots, great physical consumption, easy arm release, etc., and achieves low arm force requirements and work. The effect of high efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below we describe the present invention in detail by specific implementation case:

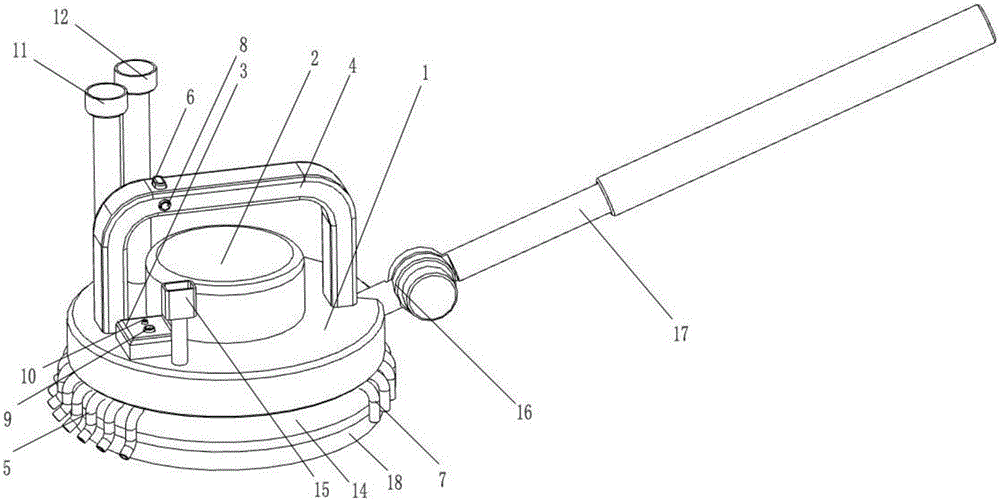

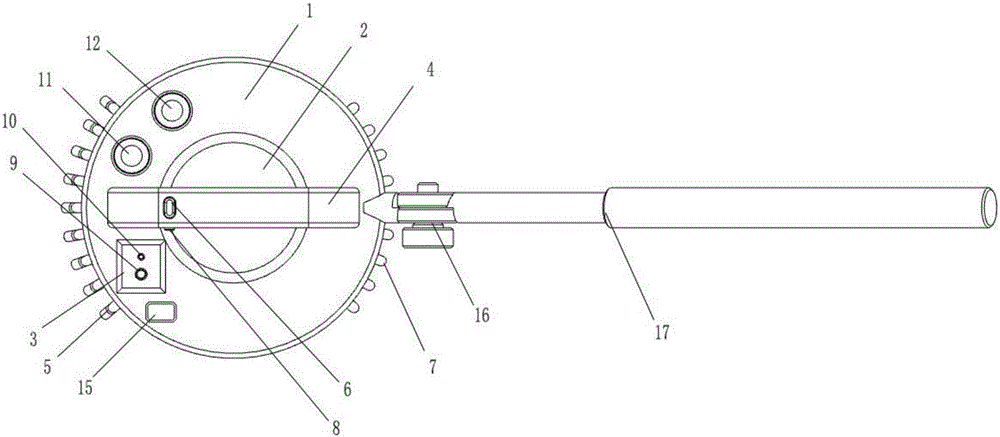

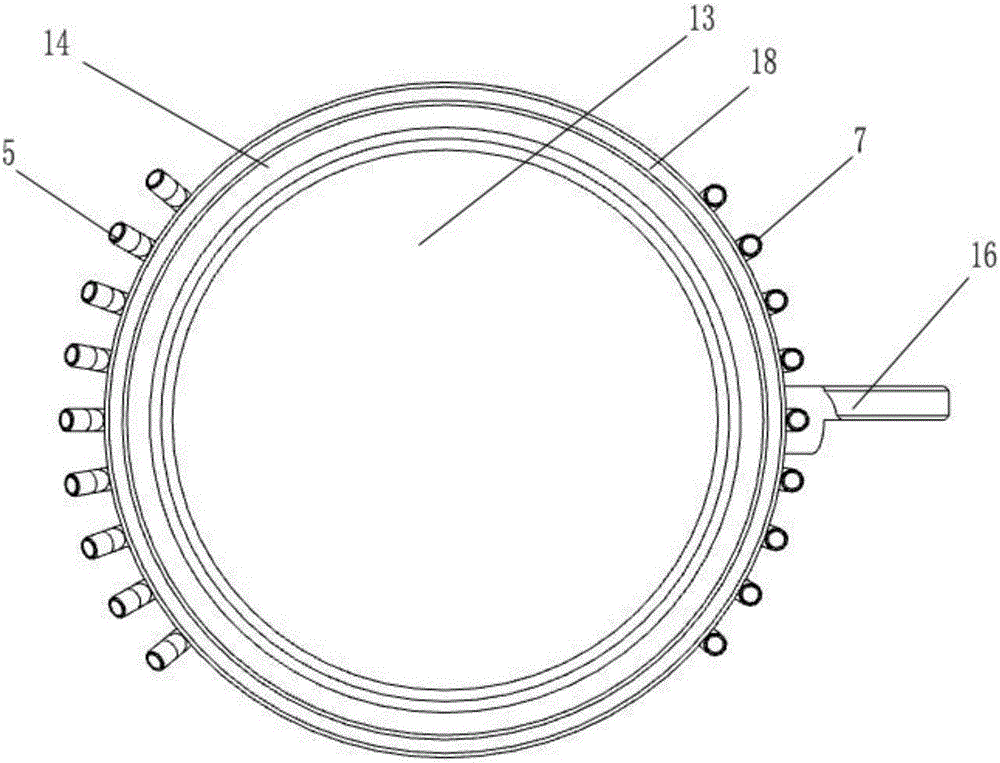

[0020] Such as figure 1 It is a three-dimensional view of an exterior wall cleaning machine of the present invention, including a base 1, a motor 2, a control module 3, a handle 4, a clean water nozzle 5, a clean water nozzle switch 6, a cleaning liquid nozzle 7, a cleaning liquid nozzle switch 8, a switch 9, and a mode Switch 10, clean water connection pipe 11, cleaning liquid connection pipe 12, cleaning tray 13, cleaning tray shield 14 and power connection wire 15, the center position of the base 1 is provided with a motor 2, and the shaft of the motor 2 There is a cleaning disc 13 connected through a shaft coupling, such as image 3 As shown, the cleaning tray 13 is provided with a disc-shaped cleaning tray shield 14, the bottom surface of the cleaning tray shield 14 is 2 cm higher than the bottom surface of the cleaning tray 13, and the bottom surface of the cleaning tray shield 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap