Method for embedding thermal shrinkage film in water discharge bent pipe

A technology of heat-shrinkable film and heat-shrinkable tube, which is applied in the field of faucets, can solve problems such as the impact on human health, and achieve the effects of avoiding health damage, improving water safety, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

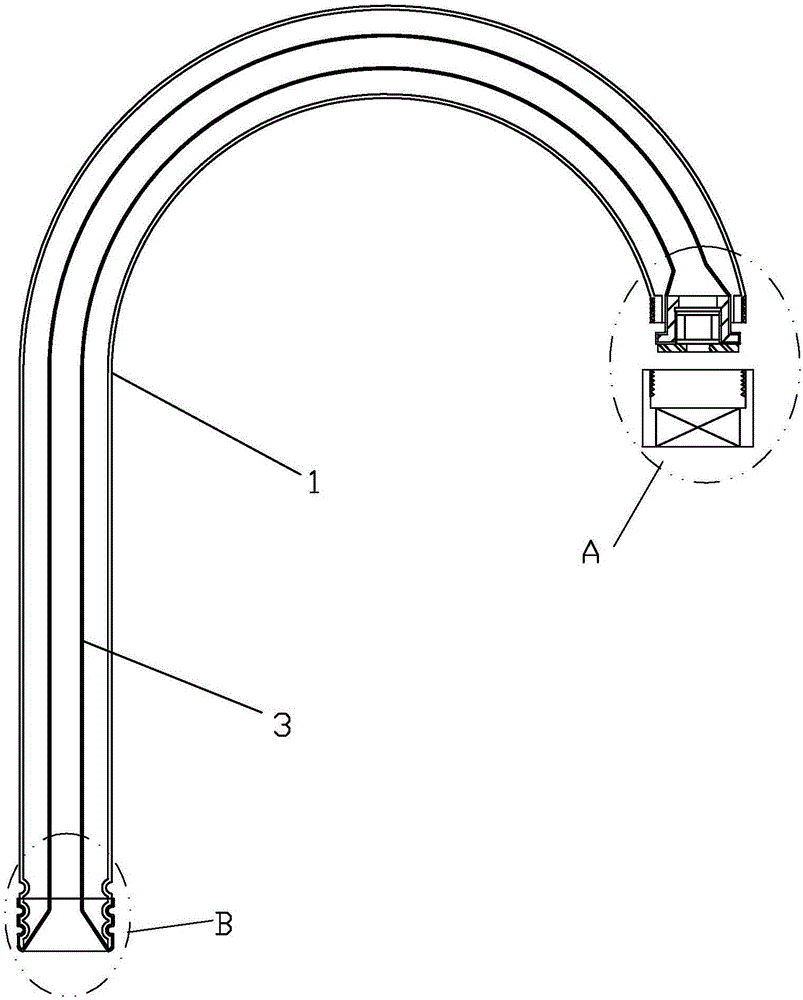

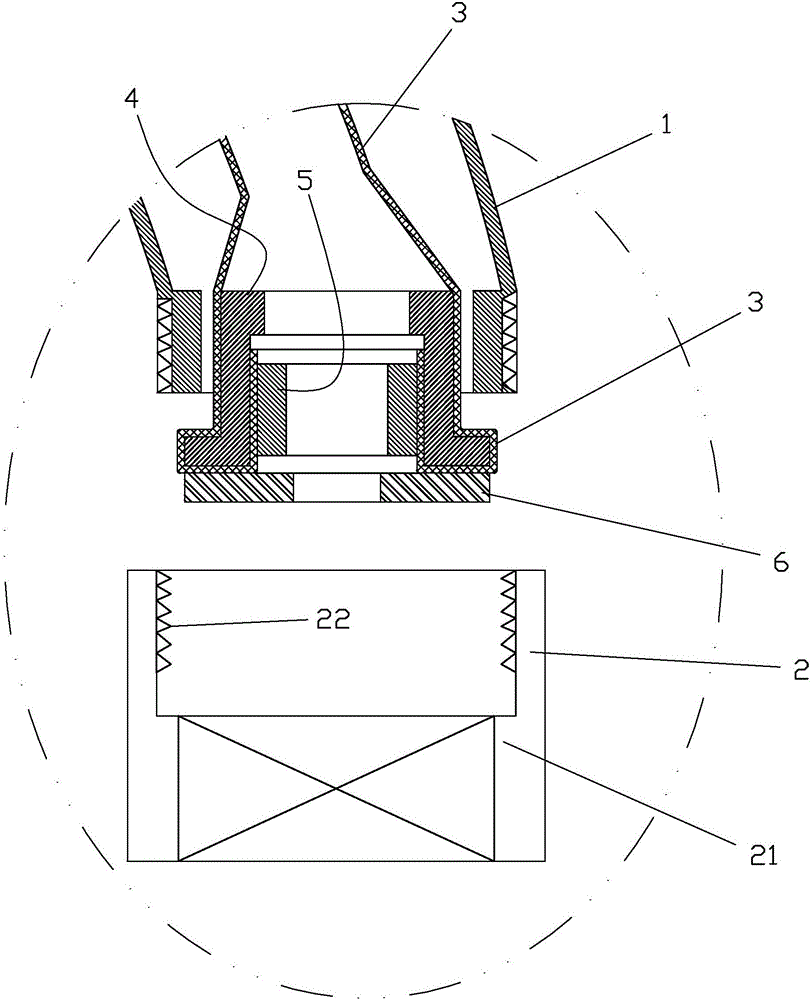

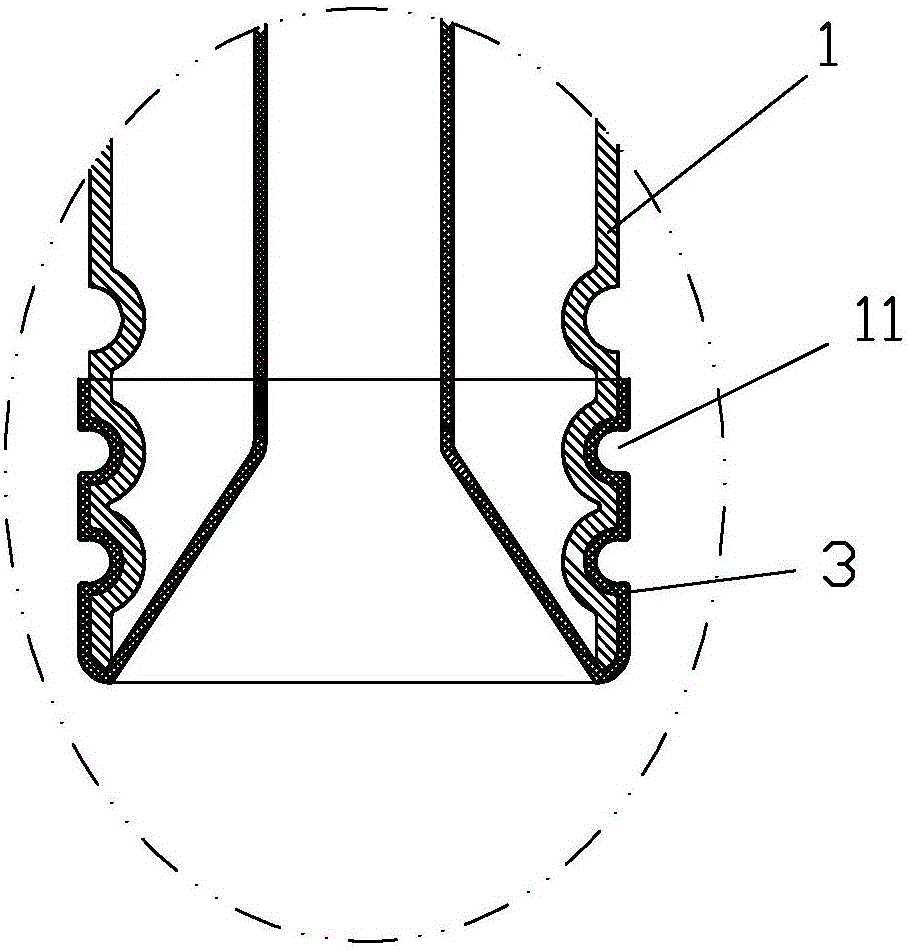

[0024] refer to Figure 1~Figure 4 , a faucet water outlet elbow with a heat shrinkable film of the present invention includes a water outlet elbow 1, the water outlet end of the water outlet elbow 1 is provided with a water outlet 2, and the water outlet elbow 1 is provided with a heat shrinkable film 3. , one end of the heat shrinkable film 3 protrudes from the water inlet end of the water outlet elbow and then is sleeved on the outer wall of the water outlet elbow, and the other end of the heat shrinkable film 3 is sleeved with a T-ring sleeve 4. The T-ring The sleeve 4 is provided with an inner concave platform 41. After the heat shrinkable film 3 is wrapped around the T-ring sleeve 4, its end is returned to the inner concave platform 41. The inner concave platform 41 is also provided with a pressure plate. The film sleeve 5 is used to pres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap