Dual-mixture dual-oxygen-supplementation combustor with positioning ignition and flame stabilizing structure and manufacturing method thereof

A burner and oxygen supplement technology, which is applied in the combustion method, burner, gas fuel burner, etc., can solve the problems of high cost, untouchable fire cover pins, and reduced combustion performance, and achieves reduced temperature and sufficient mixing. , Improve the effect of high temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

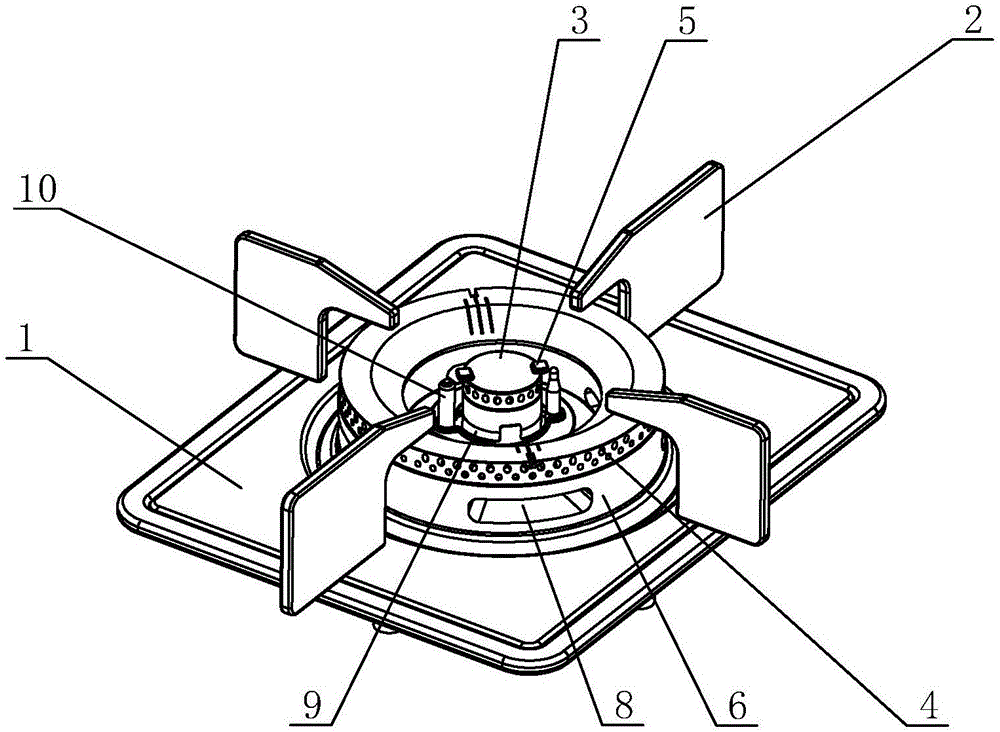

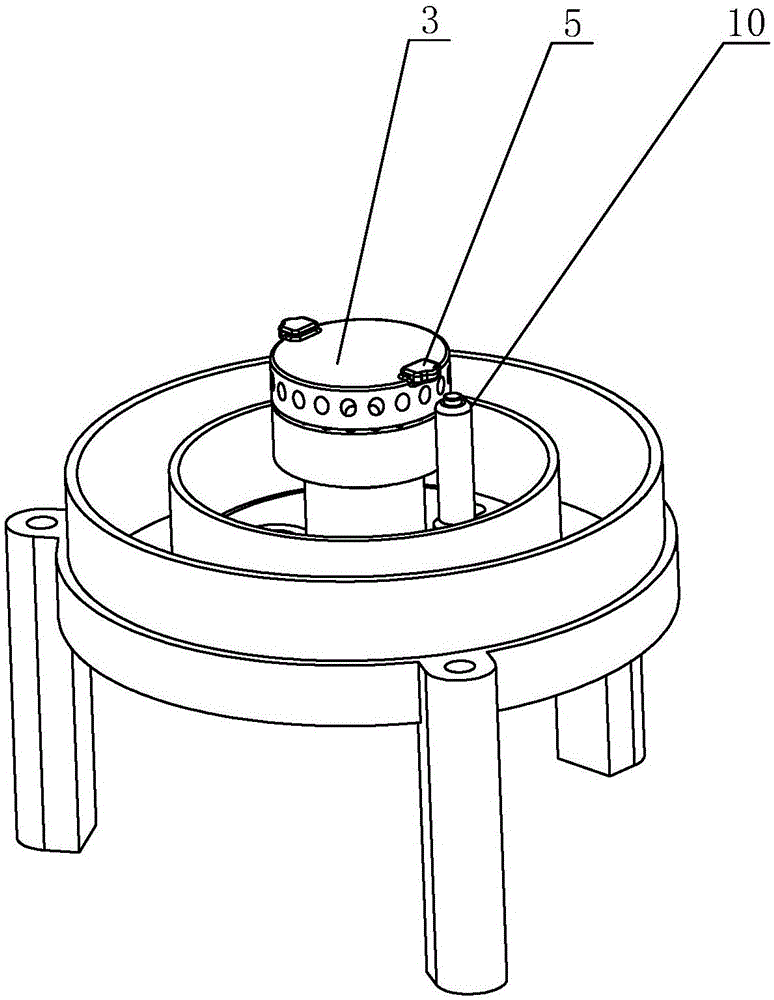

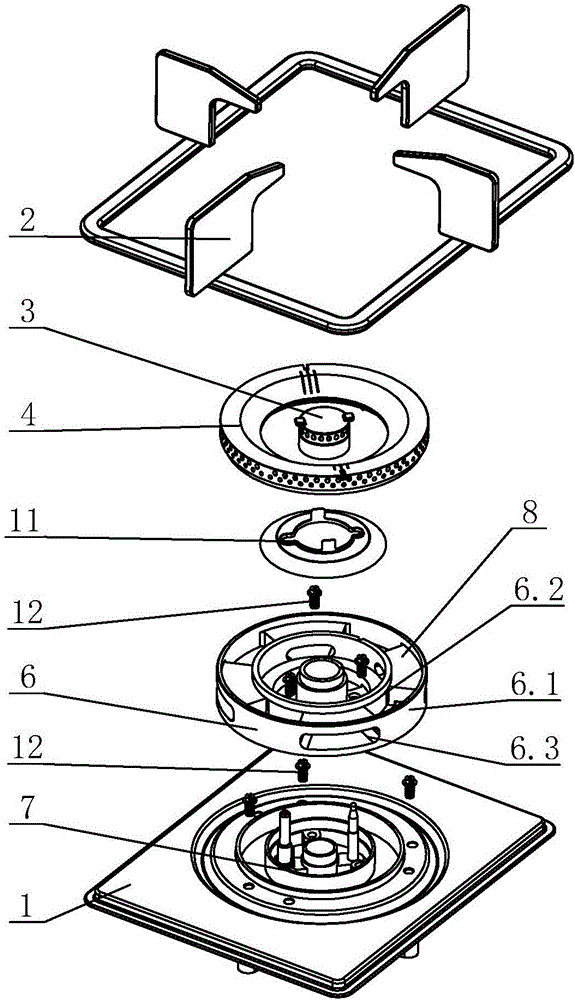

[0029] see Figure 1-Figure 4 , a dual-mixing double-oxygenation burner with a positioning ignition and flame-stabilizing structure, including a liquid receiving plate 1, a pot support 2, and an inner / outer ring fire cover 3 / 4, and a protrusion is provided on the top of the inner ring fire cover 3 The side eaves 5; the outer ring fire cover 4 is set on the upper gas mixing plate 6; the bottom of the upper gas mixing plate 6 is also provided with the lower gas mixing chamber 7; the upper gas mixing plate is provided with the first oxygen supply channel 8; the inner ring fire A second oxygen supply channel 9 is provided on the outside of the cover 3 .

[0030] There are two side eaves 5; the position of the side eaves 5 is set relative to the ignition pin 10 and higher than the ignition pin; the side eaves do not coincide with the top of the ignition pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com