Porcelain fire cover of gas stove burner

A technology for burners and gas stoves, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of easy oxidation and corrosion of the burner head, easy corrosion of the fire cover, inconvenient disassembly and cleaning, etc., so as to reduce drop damage. , The effect of reducing transportation costs and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

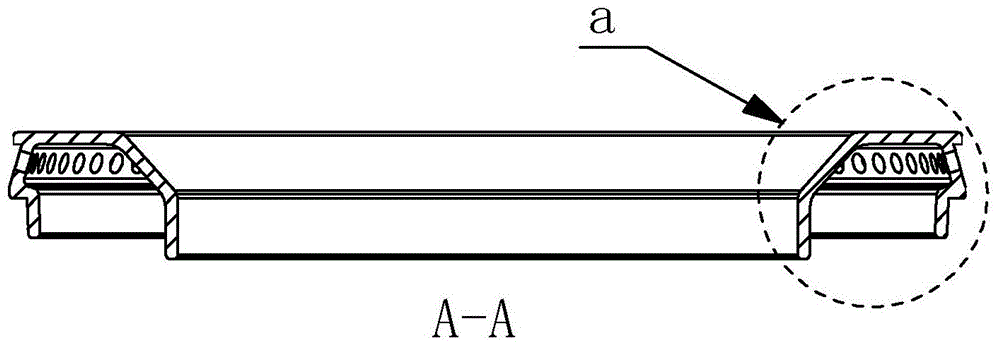

[0013] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

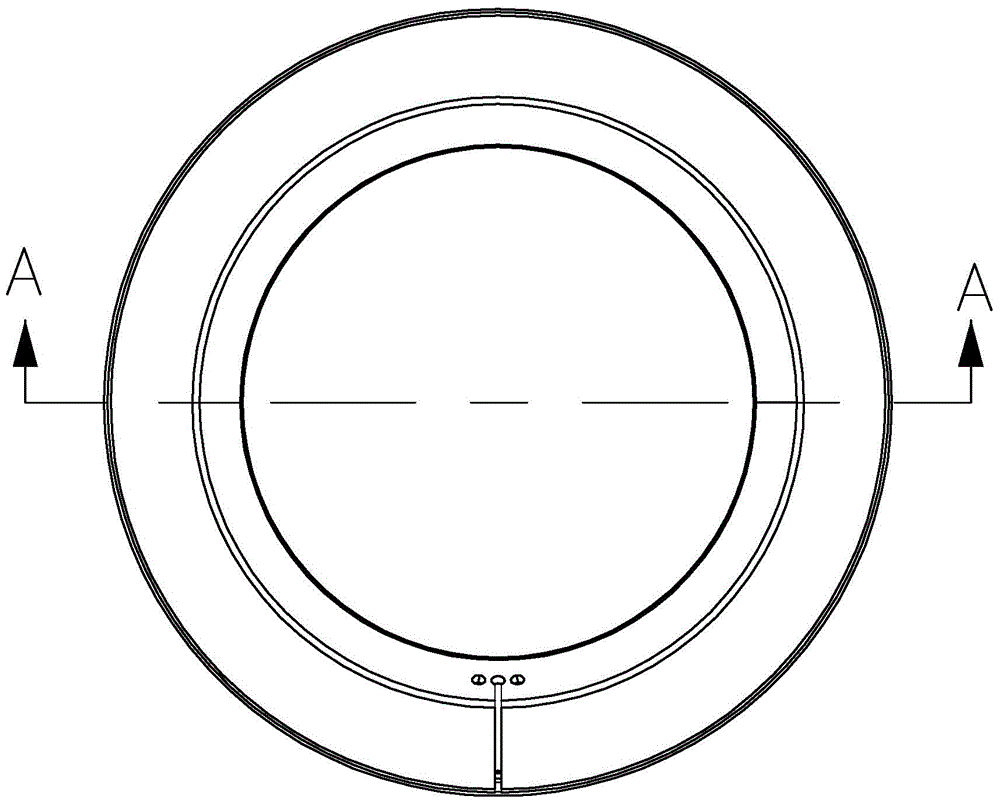

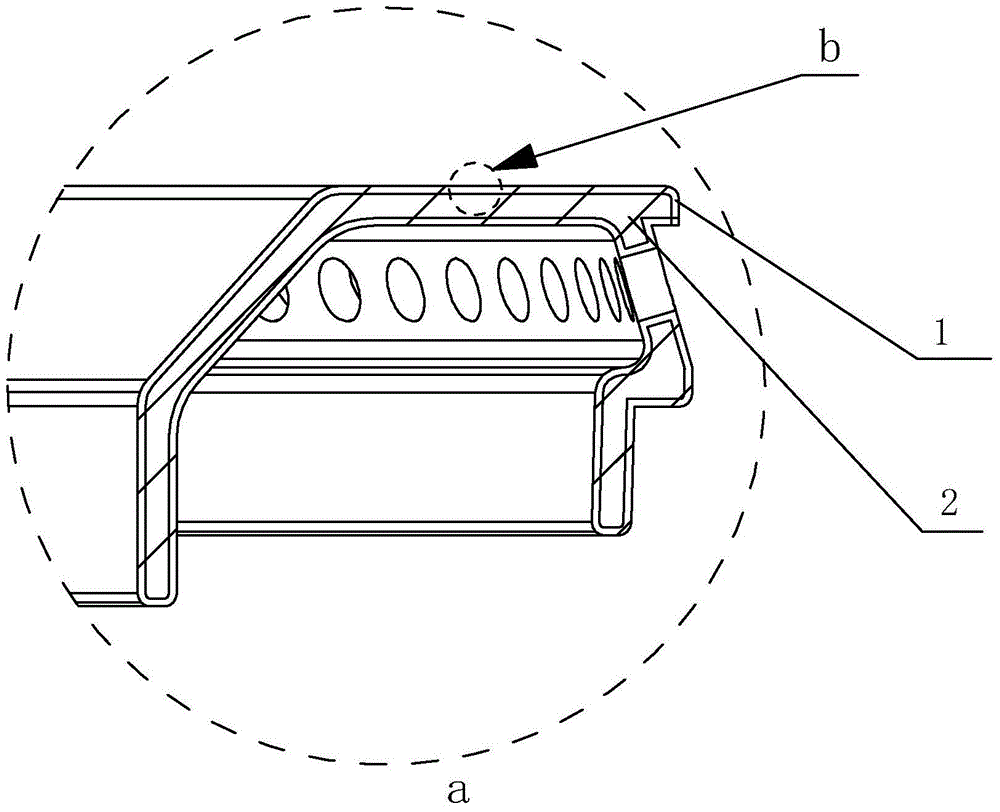

[0014] Such as Figure 1 ~ Figure 4 As shown, the fire cover of the present invention is formed by integral casting of aluminum alloy, and all surfaces of the aluminum alloy substrate of the fire cover are subjected to hard anodic oxidation surface treatment, and a porcelain hardened aluminum alloy substrate is formed on the surface of the aluminum alloy substrate 2 of the fire cover. Hard anodized film 1, the thickness of the hard anodized film 1 is not less than 0.08mm, the hard anodized film 1 includes a non-porous layer 12 and a porous layer 13 distributed in sequence from the aluminum alloy substrate 2, the non-porous layer 12 and the The aluminum alloy matrix 2 is interpenetrated and bonded.

[0015] In the above solution, the fire cover can also be formed by extruding aluminum alloy plates, pipes, and rods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com