Eccentric stove

An eccentric stove and stove body technology, which is used in household stoves/stoves, lighting and heating equipment, solid heating fuels, etc. problem, to achieve the effect of easy promotion, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

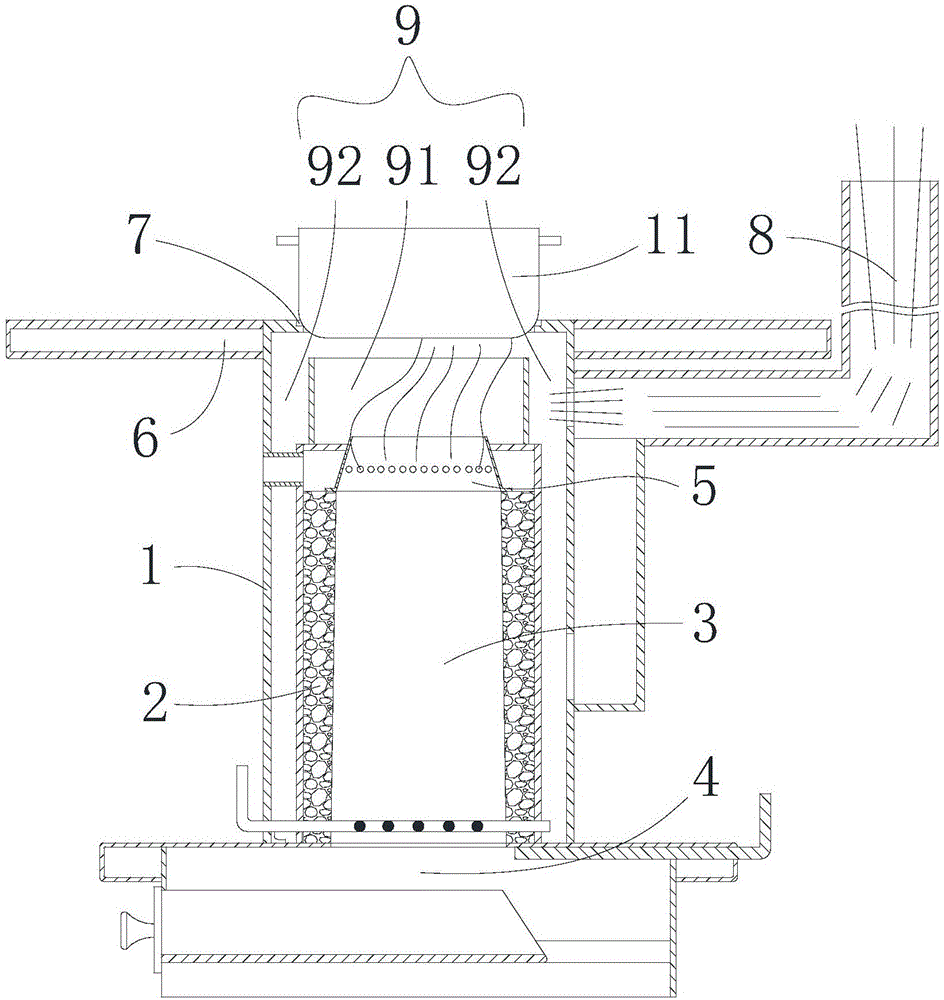

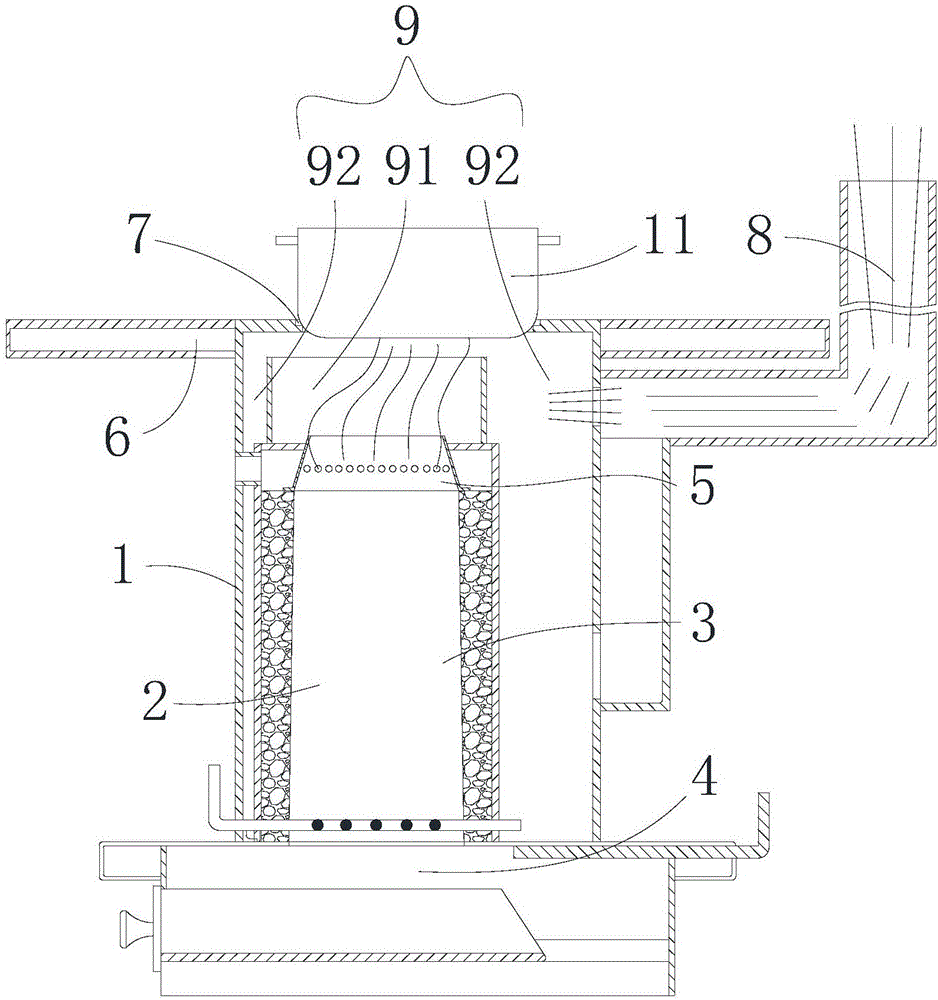

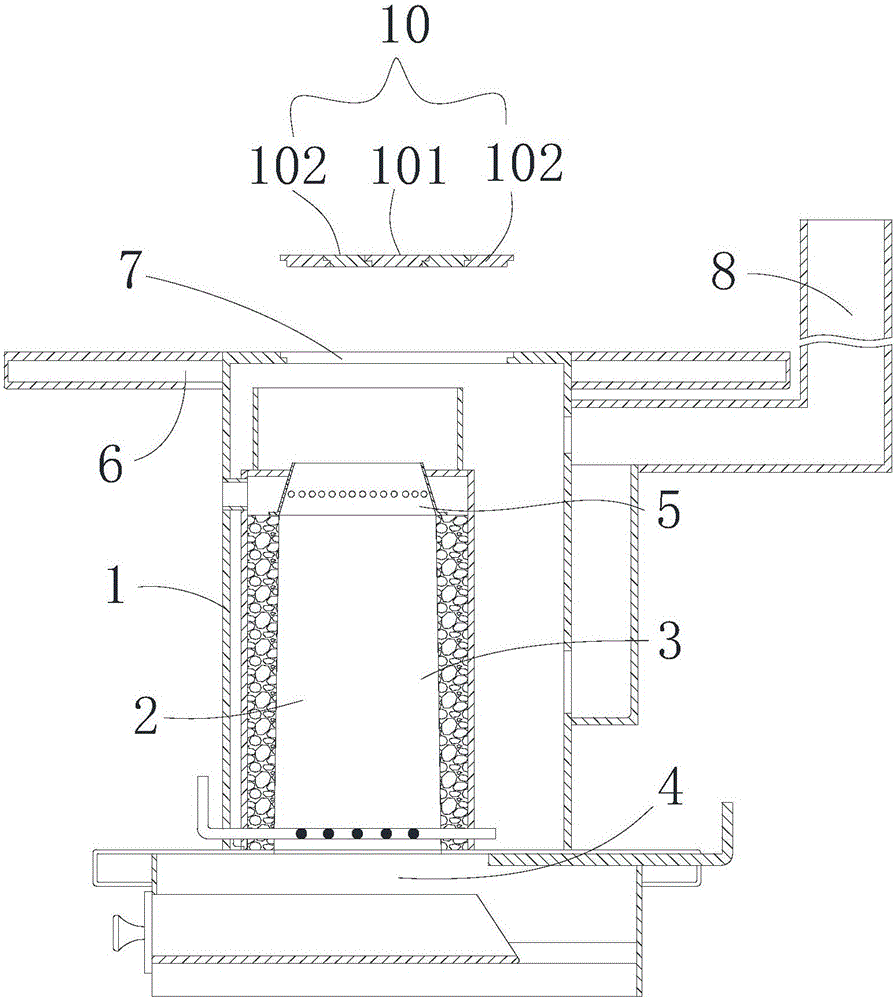

[0036] Such as Figure 2-3 As shown, an eccentric stove according to the present invention includes a furnace body 1 .

[0037] The furnace body 1 is provided with a furnace core 2, the furnace body 1 is higher than the furnace core 2, the furnace core 2 is provided with a furnace 3, and the lower end of the furnace body 1 and the furnace core 2 is provided with a furnace The base 4, the upper end of the furnace core 2 is provided with a combustion head 5, the upper end of the furnace body 1 is provided with a furnace platform 6 for supporting the stove, the furnace platform 6 is provided with a fire outlet 7, and the fire outlet 7 is used for setting Cooker 11, a flue 8 is communicated between the combustion head 5 and the fire outlet 7, the entrance of the flue 8 is located on the furnace body 1, and the centroid of the fire outlet 7 is located at the centroid of the combustion head 5 The area between the inlet of the flue 8 ; wherein, the centroid of the fire outlet 7 coin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com