Air seal system to reduce dust accumulation and sticking on water wall of waste heat boiler of silver copper smelting furnace

A technology for waste heat boilers and copper smelting furnaces, used in furnaces, furnace components, waste heat treatment, etc., can solve the problems of soot adhesion on water-cooled walls, lack of mature technology, and complex smelting systems. The effect of reducing gas dust content and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

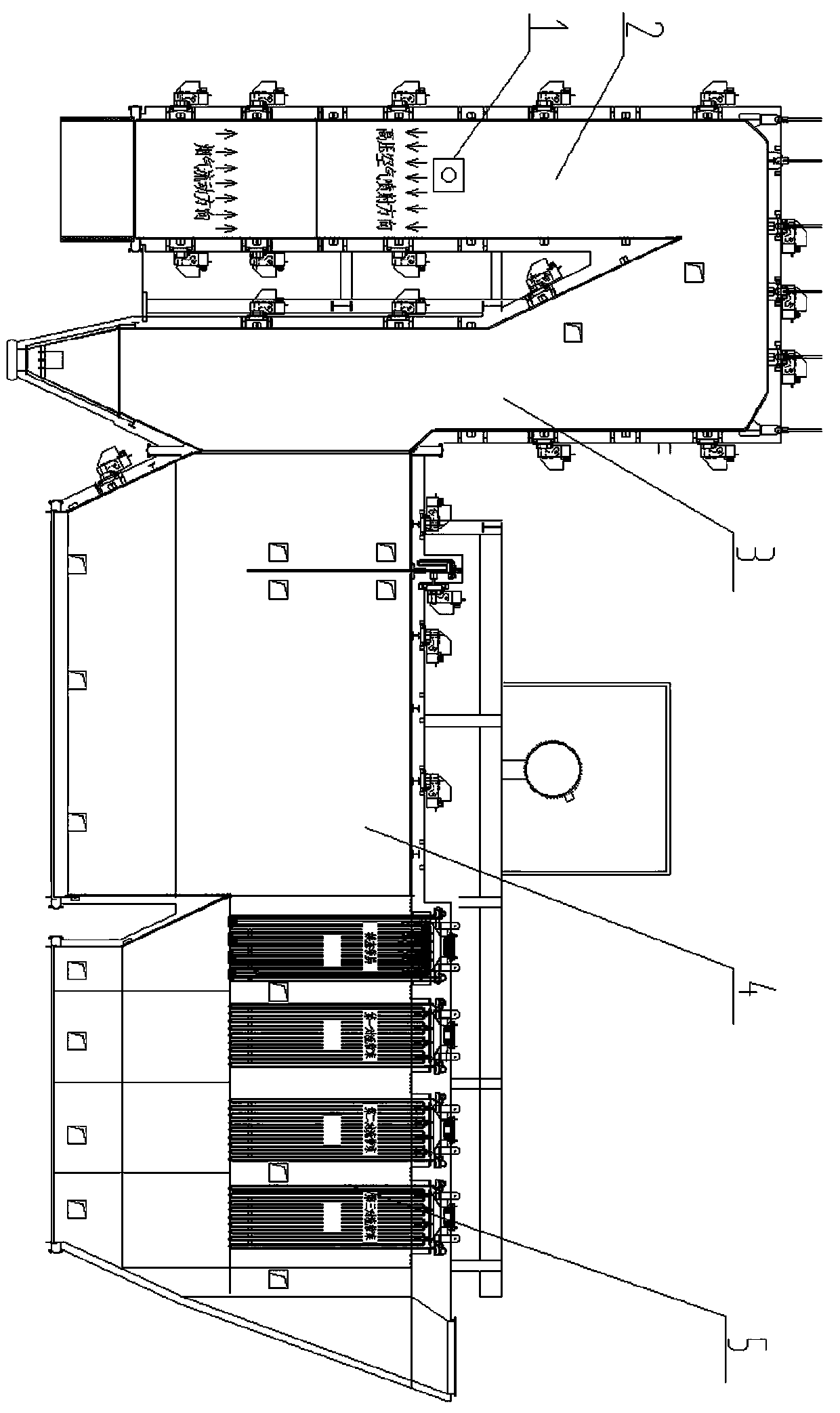

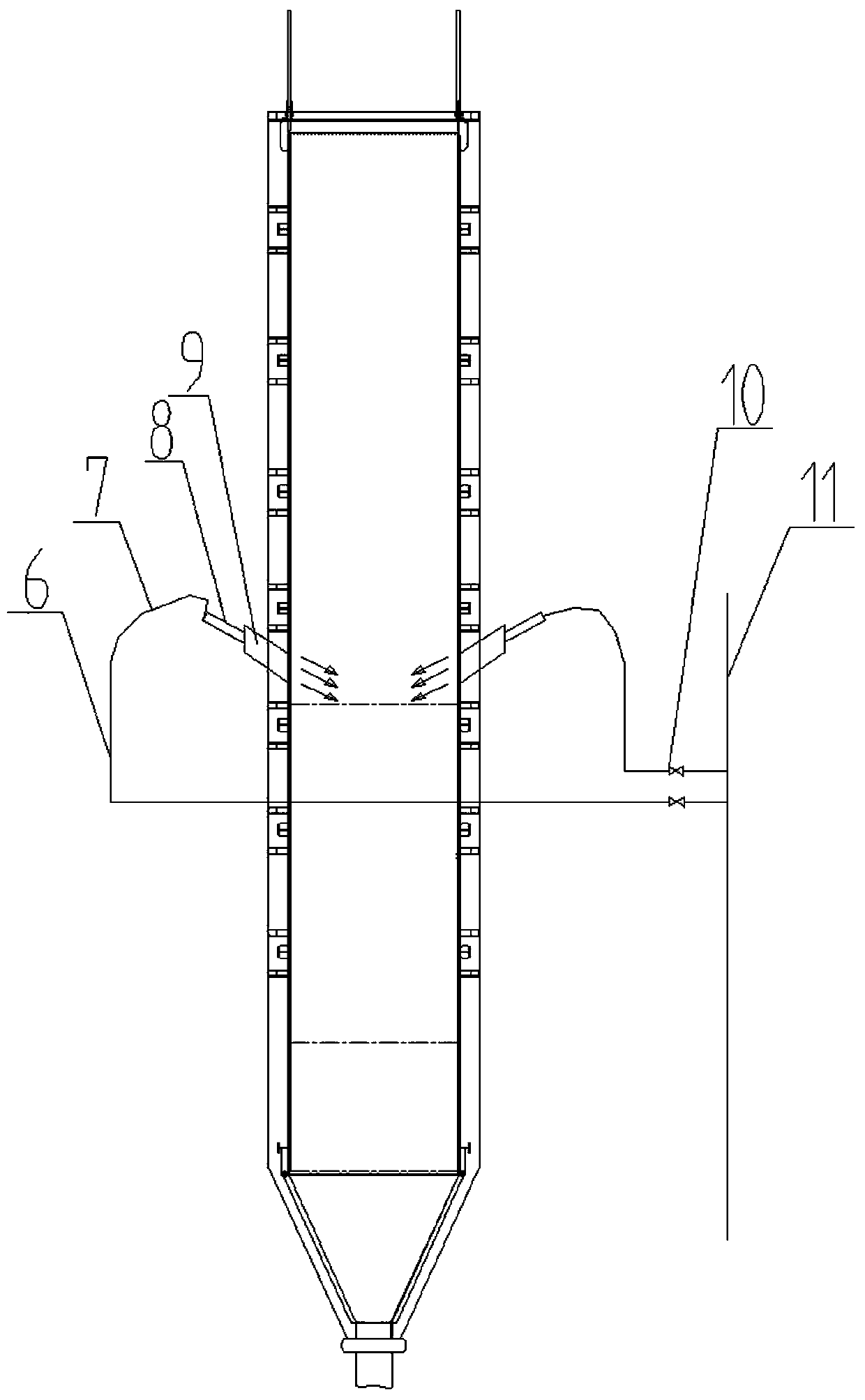

[0015] An air seal system for reducing dust accumulation and sticking on the water-cooled wall of the waste heat boiler of a silver copper smelting furnace. The tail end of chamber 5 is provided with a flue gas outlet, and the implementation steps are as follows:

[0016] (1) Convey the compressed air to the boiler ascending flue 2 through the high-pressure air main pipe 11, and install a stainless steel stop valve and a remote flowmeter on the high-pressure air main pipe 11;

[0017] (2) Install the high-pressure air spray gun 8 and the spray gun seat 9 at the predetermined elevation of the rising flue of the boiler, and the center position of the plate-tube water wall on both sides. The high-pressure air spray gun 8 is fixed and installed. Downward, the high-pressure air spray gun 8 is communicated with the high-pressure air main pipe 11, and the high-pressure air main pipe 11 is connected with the air pressure pipe network of the power center of the factory area. ;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com