A method for testing susceptibility to intergranular corrosion of austenitic stainless steel

An austenitic stainless steel, intergranular corrosion technology, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of increasing repetitive work, difficulty in sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

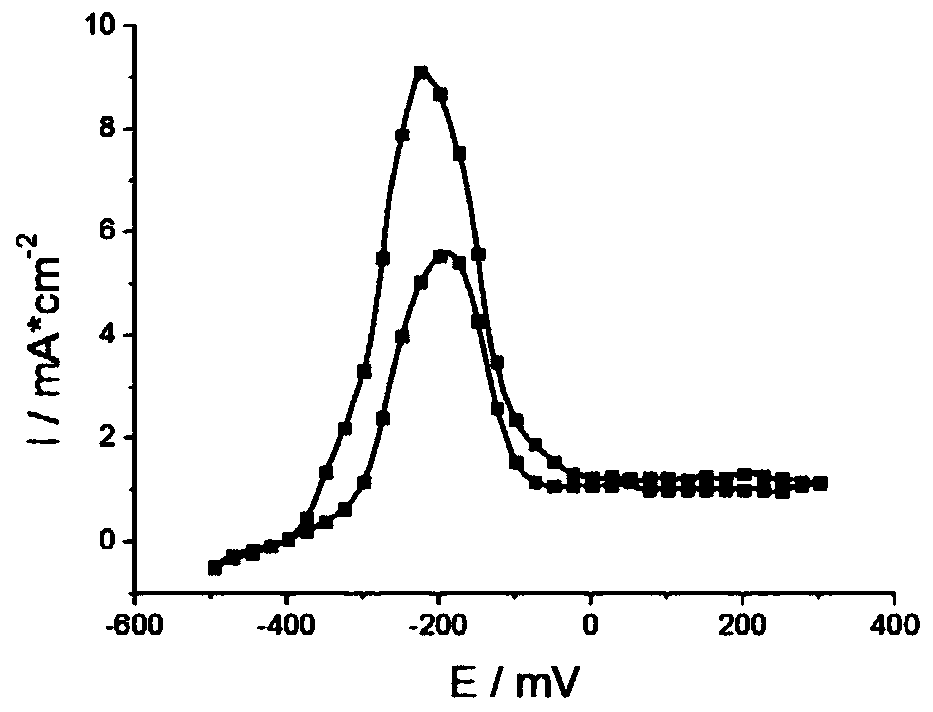

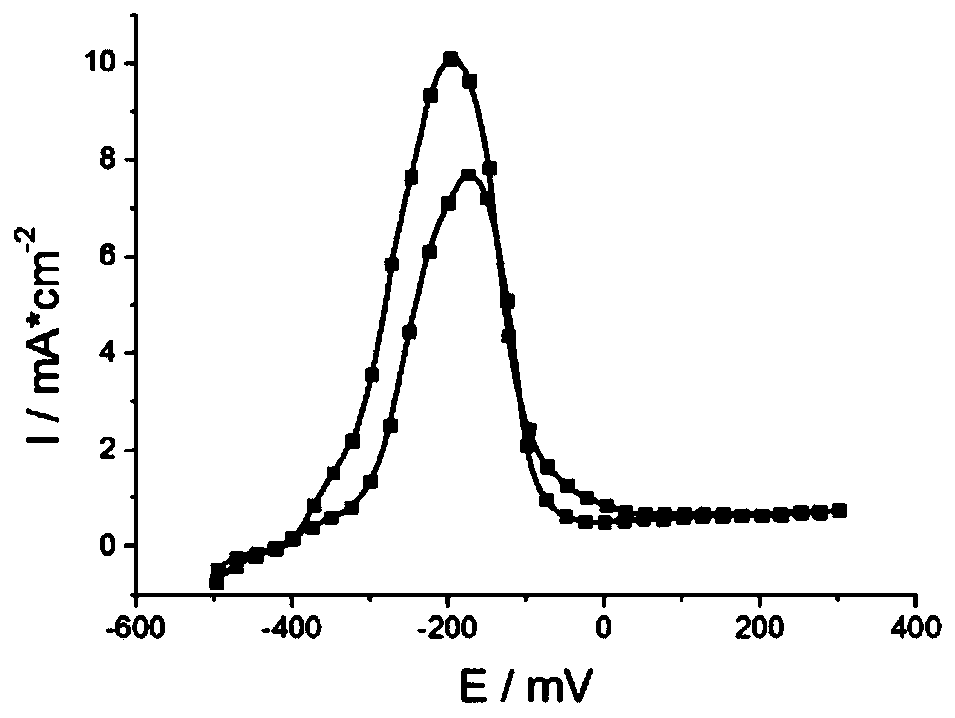

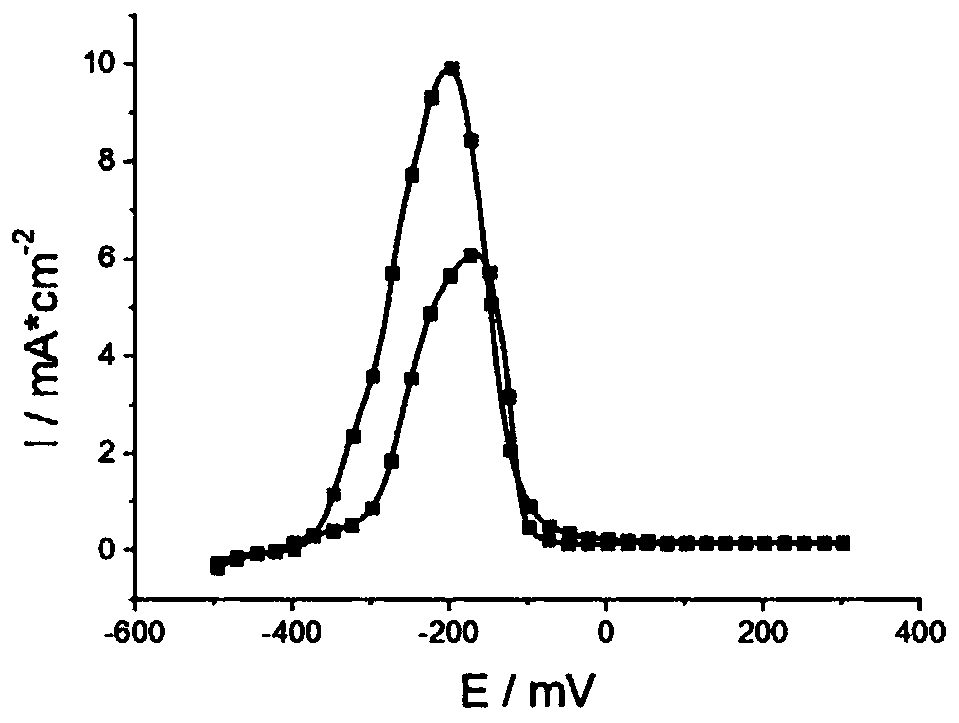

Image

Examples

Embodiment 1

[0045] It is used to illustrate the method for testing the susceptibility to intergranular corrosion of austenitic stainless steel in the present invention,

[0046] Prepare the electrolyte: mix sulfuric acid, sodium chloride and sodium sulfate to form an electrolyte with a sulfuric acid concentration of 1.0mol / L, a sodium chloride concentration of 0.5mol / L, and a sodium sulfate concentration of 1.0mol / L;

[0047] Preparation of working electrodes: Inlay epoxy resin (epoxy resin from Yamekai New Materials Co., Ltd., model E44) in the aforementioned austenitic stainless steel samples 1-3 to prepare the working electrodes 1-3 to be tested, and The prepared working electrodes 1-3 to be tested were polished step by step with sandpaper, then mechanically polished and the working surface was cleaned with alcohol.

[0048] Establish a three-electrode system: use the previously prepared working electrodes 1-3 and the electrolyte to establish a three-electrode system (the auxiliary ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com