Abrasive belt grinding type all-type steel rail grinding device and method

A technology of abrasive belt grinding and rail, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of excessive dependence on equipment and its own performance, and achieve the effects of reducing excessive dependence, convenient replacement, and lower requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate those skilled in the art to fully understand the technical content of the present invention, the present invention will be described below with reference to specific examples. These examples are intended to further illustrate the advantages and features of the invention, not to limit the invention.

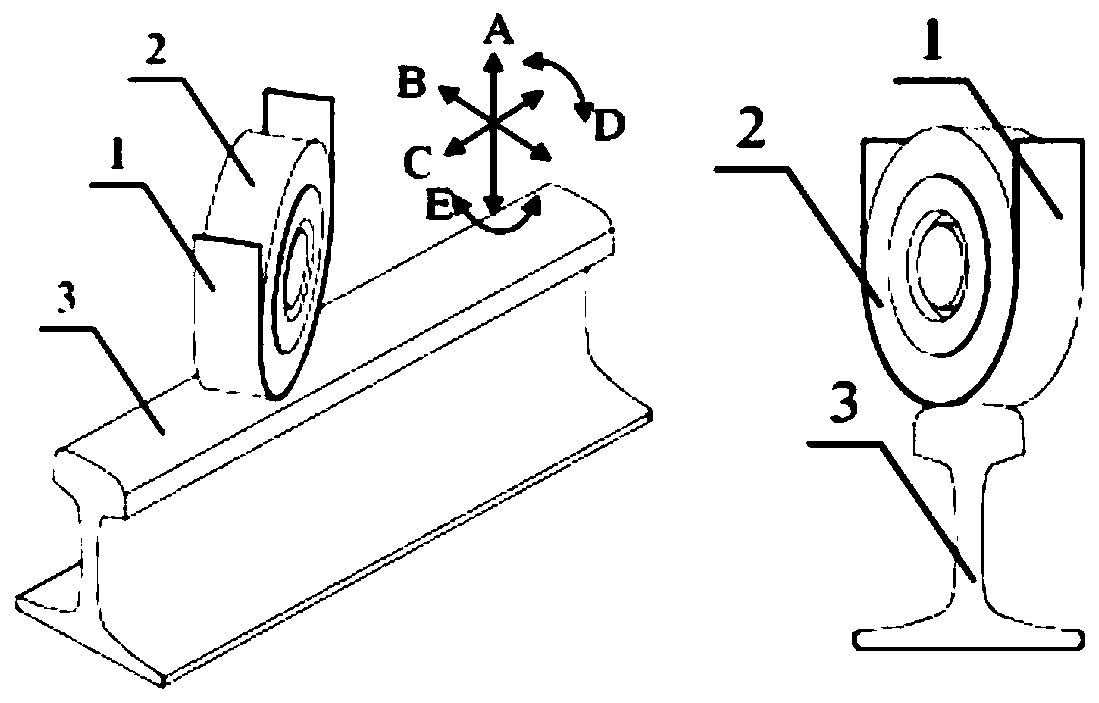

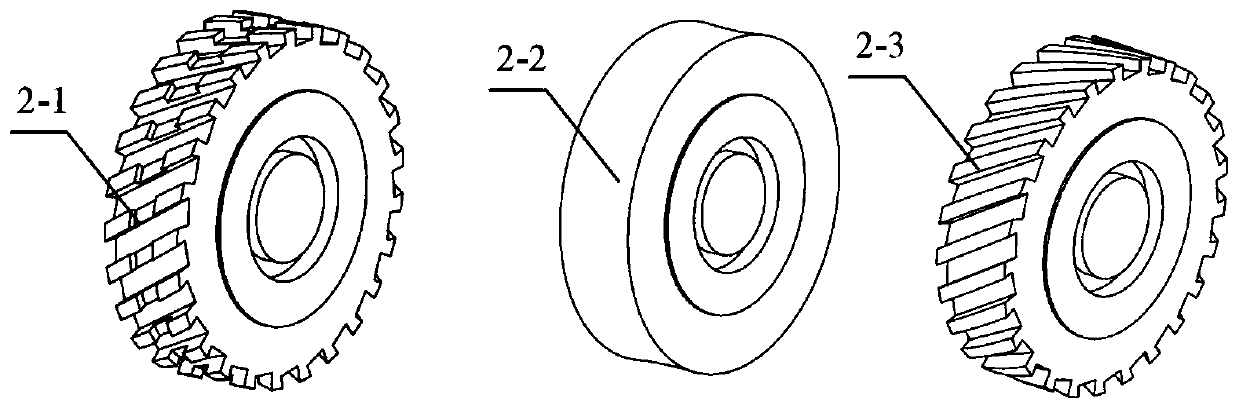

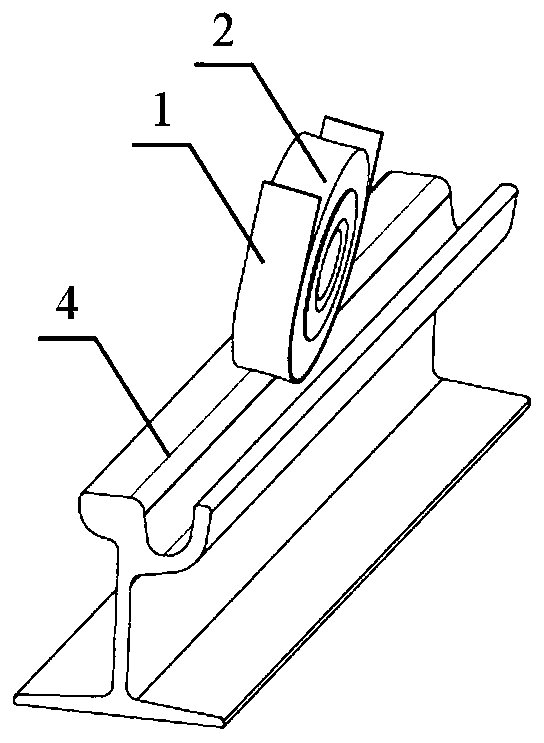

[0026] like figure 1 As shown, an abrasive belt grinding type all-type rail grinding method is to use the abrasive belt 1 to interact with the rail 3 under grinding pressure to remove material, wherein the contact wheel 2 directly applies pressure to the abrasive belt 1 for grinding; The abrasive belt 1 and its gear train can realize vertical A, transverse B, and longitudinal C linear motion along the surface of the rail, and can realize rotational motions E and D around A and C axes.

[0027] The A, B, C, D and other motion forms of the abrasive belt and its gear train are set to adapt to different rail grinding target profiles, and the motion form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com