A DC high voltage measurement and correction system and method based on DC voltage divider time-division sampling

A technology of DC voltage divider and time-sharing sampling, which is applied in the direction of measuring current/voltage, only measuring voltage, measuring devices, etc. It can solve the problem that it is difficult to improve the measurement accuracy technology, the cost performance is not high, and the DC voltage divider Accuracy impact and other issues, to achieve the effect of measurement and correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

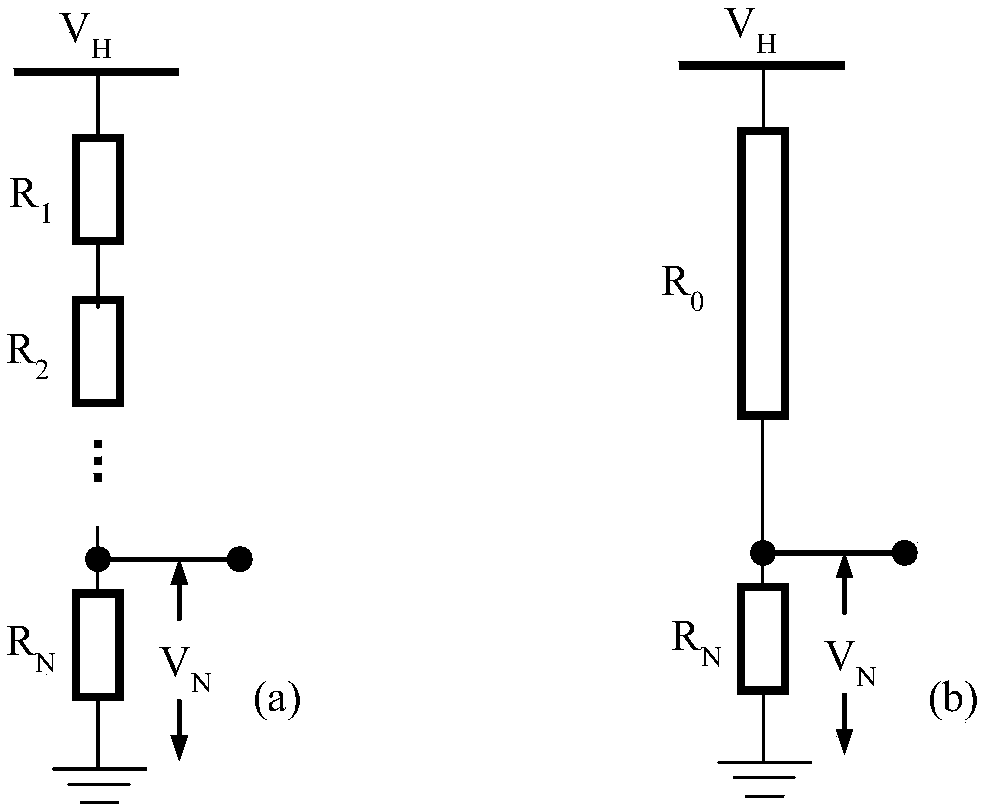

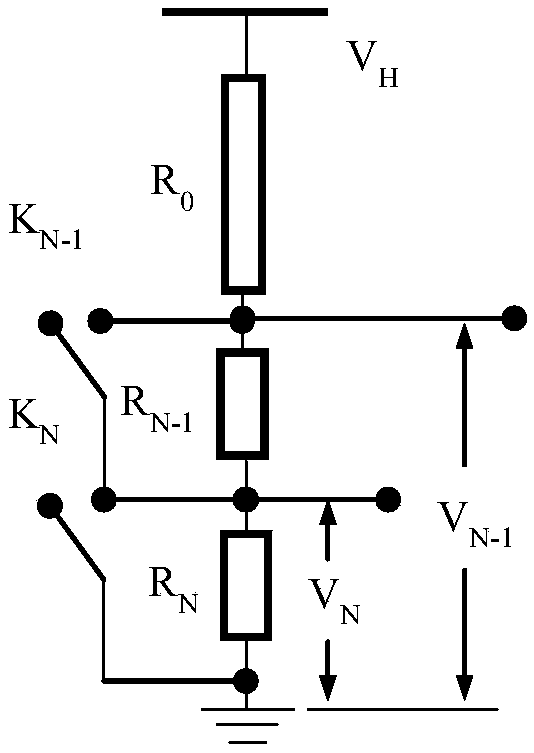

Method used

Image

Examples

Embodiment

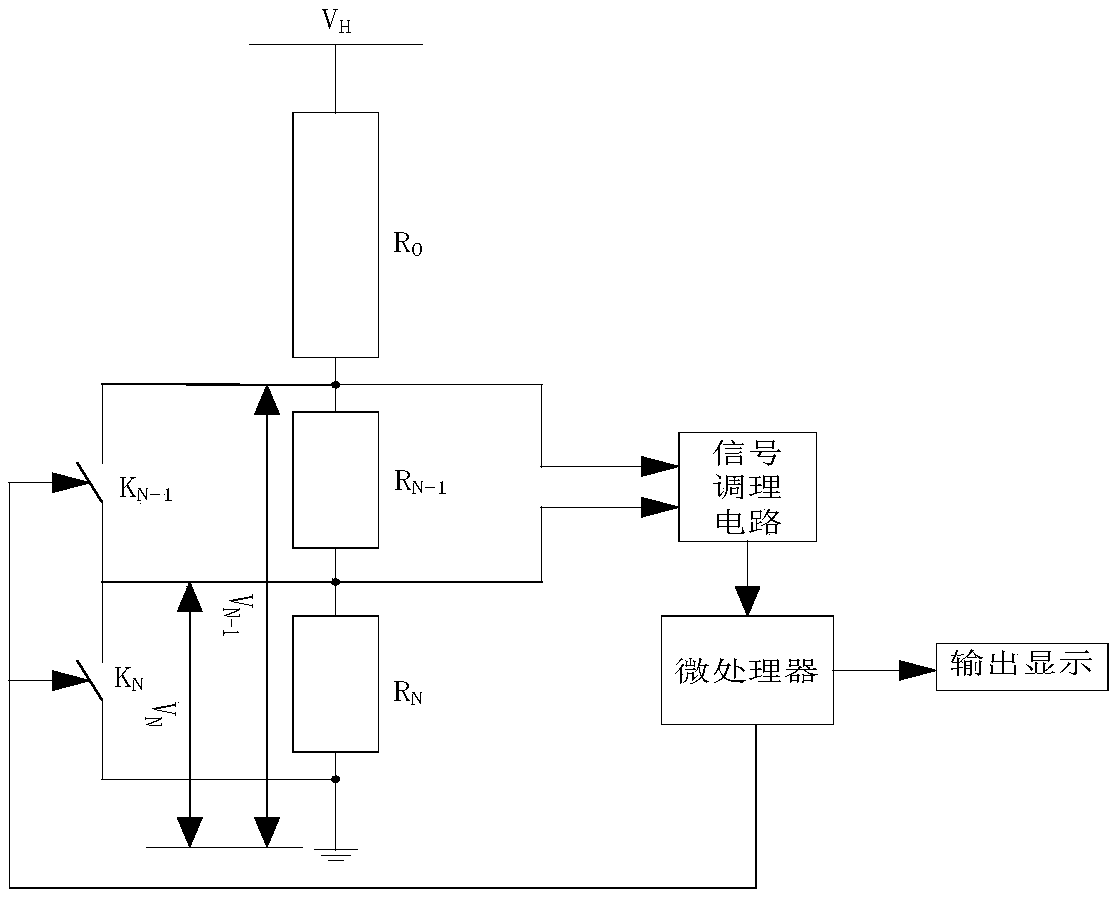

[0057] This embodiment combines image 3 A schematic diagram of the measurement system structure briefly illustrates the implementation process. Assuming that the measured DC voltage is 100kV, the system uses a MOSFET tube as a switch, which is turned on when the gate is high voltage, and the C51 single-chip microcomputer is used as a microprocessor. The quasi-bidirectional port of the single-chip microcomputer is used to control the MOSFET tube. , the resistance value of each resistor is 1MΩ, the rated power is 2W, the resistance value of the precision resistors is 50kΩ, and the accuracy level requirement of the DC voltage divider is 0.5. Therefore, at rated voltage, R N The voltage V N about 50V, R N-1 The voltage V N-1 It is about 100V, the resolution of the acquisition card is 16 bits, the voltage input range is 0-5V, and the conditioning circuit converts V N and V N-1 Regulated into 0 ~ 5V. The measurement process of the voltage divider, the realization of the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com