PLC control system for rubber-insulated wire optical cable cutter

The utility model relates to a technology of a sheathed optical cable and a control system, which is applied in the field of PLC control system of a sheathed optical cable splitting machine, which can solve the problems of high equipment failure rate and low production efficiency of single-reel winding, and achieve the effect of avoiding low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

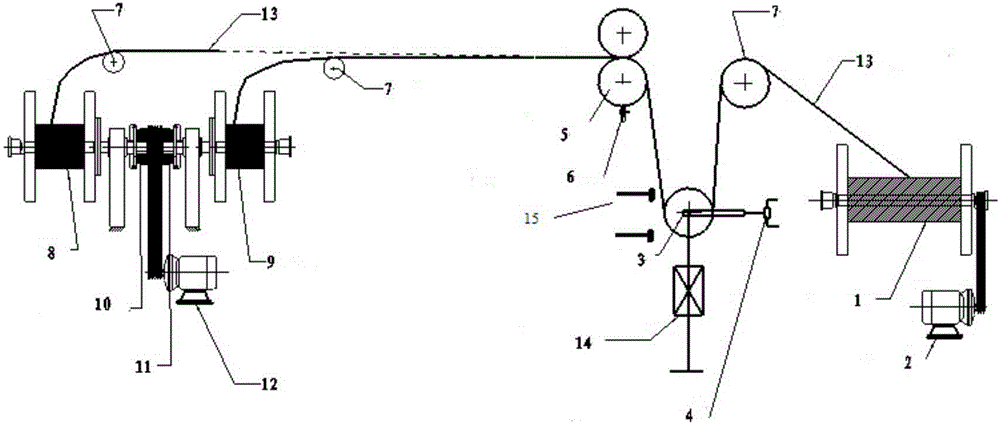

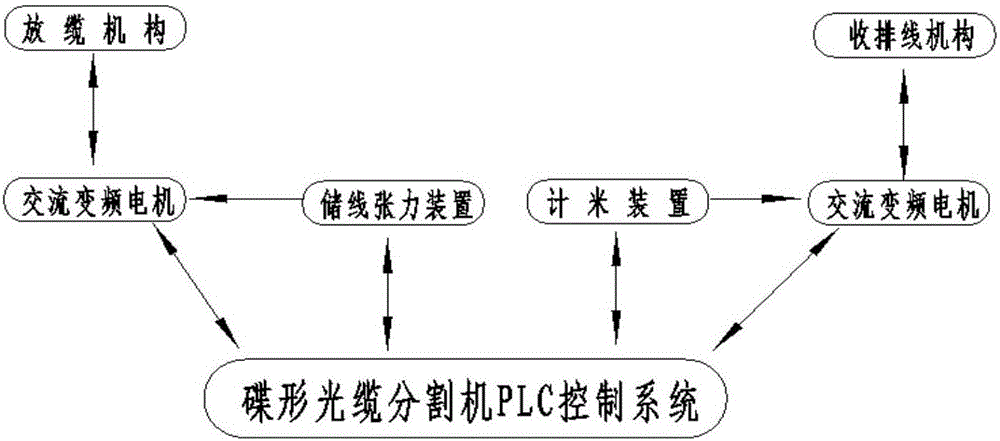

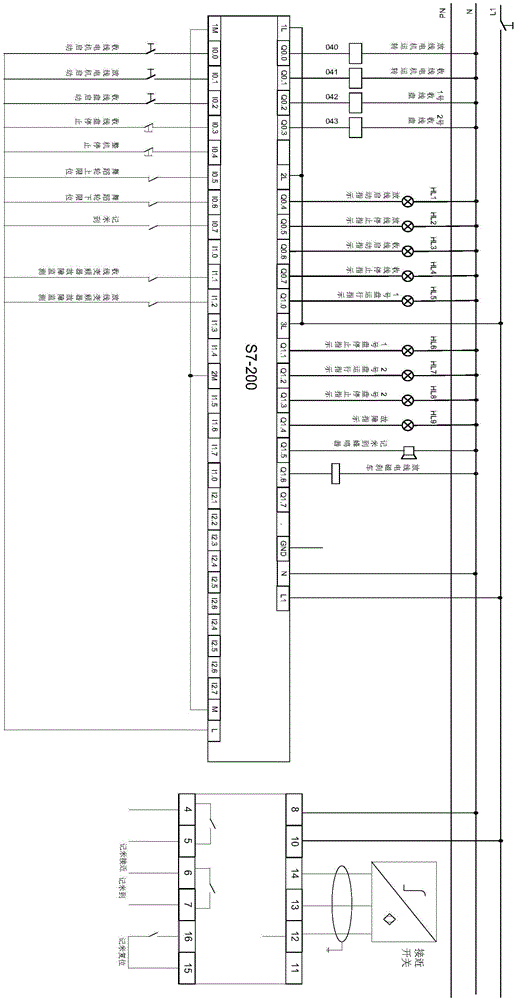

[0023] like figure 1 Shown is the structural representation of the PLC control system of the leather wire optical cable splitting machine of the present invention, figure 2 It is a block diagram of the PLC control system. The system includes a cable unwinding mechanism, a wire storage tension device, a meter counting device, a wire receiving and discharging mechanism, and a PLC controller. 1 is the pay-off reel, 2 is the pay-off motor, 3 is the wire storage tension wheel, 4 is the storage wire tension potentiometer, 5 is the pressure wheel of the meter counter, 6 is the proximity switch of the meter counter, 7 is the wire passing guide wheel, 8 is the No. 1 take-up reel, 9 is the No. 2 take-up reel, 10 is the No. 1 take-up electromagnetic clutch, 11 is the No. 2 take-up electromagnetic clutch, 12 is the take-up motor, 13 is the dish-shaped optical cable, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com