Transmission case body valve deck fastening design system and method

A transmission box and fastening technology, which is applied in the field of product design based on modeling software, can solve problems such as difficulty in meeting development requirements, complex space layout, and low design efficiency, so as to improve product design quality, avoid design errors, and save energy. Design Time Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

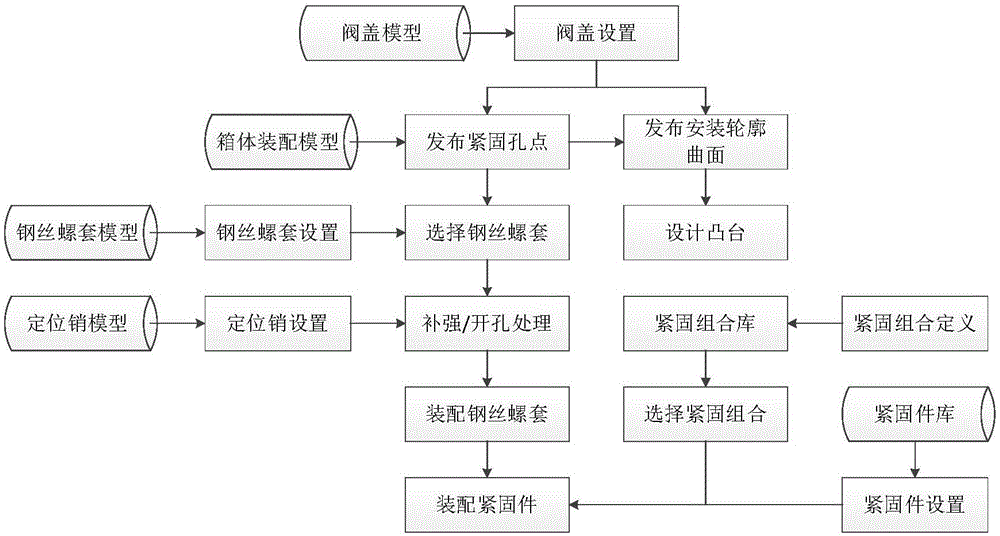

[0035] Such as figure 1 As shown, the method and system for the fastening design of the transmission box valve cover based on the three-dimensional model of Pro / E includes the following steps:

[0036] S10, marking relevant parameters in the preprocessing model;

[0037] The preprocessing model can be a bonnet model, an embedded part model or a fastener model.

[0038] For the reference setting definition of the bonnet model, it provides a geometric positioning reference for the subsequent hole fastening setting. Setting reference content mainly includes the following aspects:

[0039] 1) The positioning coordinate system of the bonnet model is mainly used to release the position of the holes on the model components;

[0040] 2) The installation plane of the bonnet model, which is used for subsequent boss design, etc.;

[0041] 3) The fastening plane of the bonnet model is used as a reference for subsequent fastener assembly;

[0042] 4) The installation hole coordinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com