Bottling method

A bottling and bottle technology, which is applied in the direction of instruments, coin-operated equipment for distributing discrete items, coinless or similar appliances, etc., can solve the problems of high cost, use, complex structure, etc., and achieve fast bottling and volume small, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

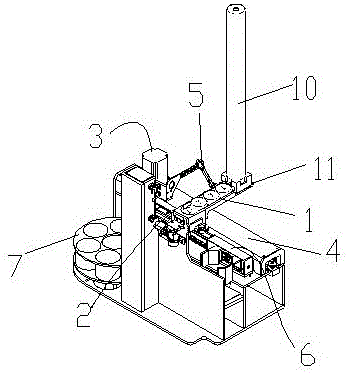

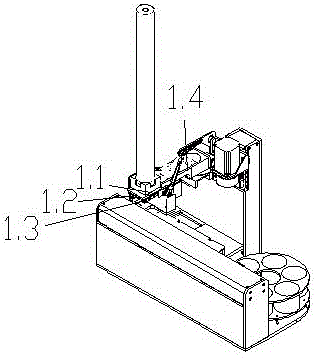

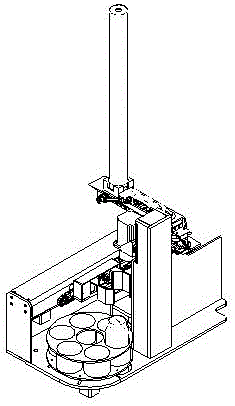

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033]

[0034] according to Figure 1-10 Shown, the present invention provides the bottling method of above-mentioned bottling device, and this method comprises the following steps:

[0035] Initial bit steps:

[0036] In this step, the manipulator 6 is in the bottle delivery position, and the left and right paws of the manipulator 6 are in the open state; the cap tightening mechanism 3 is in the upper limit position; the cap-out base 2.4 is equipped with a 1# bottle cap, and the cap-out stopper 2.1 is in a closed state; 1 # Put the bottle cap on the cover plate 2.1.

[0037] Filling steps:

[0038] In this step, after the bottle 9 is in place, the left and right claws of the manipulator 6 grab the bottle 9; the manipulator 6 moves the bottle 9 to the filling position through the traverse mechanism 4 for filling.

[0039] Delivery steps:

[0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com