Thin film transistor, production method thereof, array substrate and display device

A technology of thin film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as poor display contrast, influence of aperture ratio of display devices, large off-state current, etc., to improve display contrast, Improve the display effect and reduce the effect of off-state current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

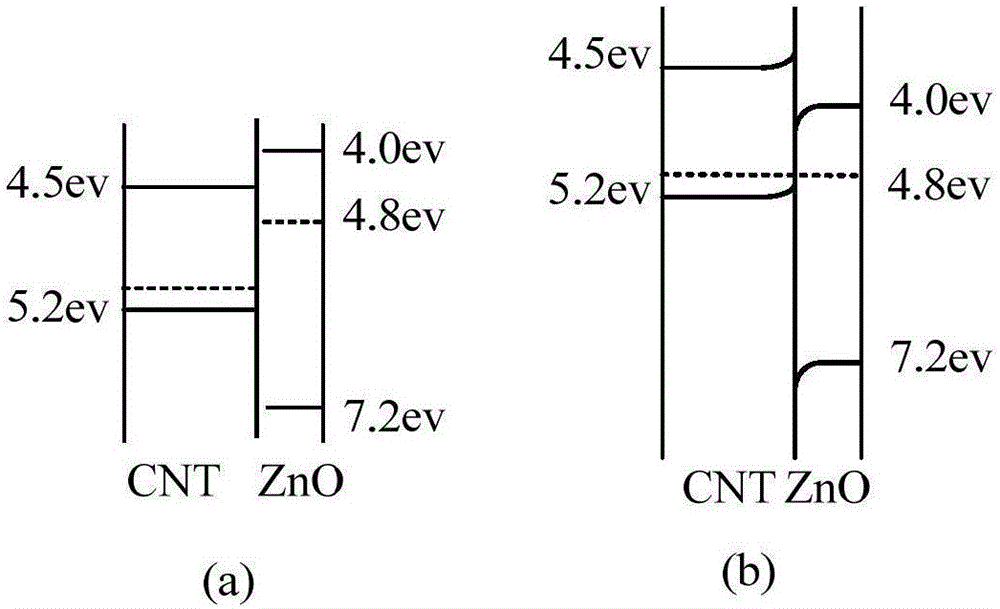

[0052] This embodiment provides a thin film transistor, the thin film transistor includes a gate, a gate insulating layer, a source, a drain and an active layer on a base substrate, between the active layer and the drain A unidirectional conduction device is formed, so that electrical signals are transmitted from the active layer to the drain via the unidirectional conduction device.

[0053] In this embodiment, a unidirectional conduction device is formed between the active layer and the drain of the thin film transistor. When the potential of the active layer is higher than the potential of the drain, the unidirectional conduction device is turned on; When the potential is lower than the potential of the drain, the unidirectional conduction device is cut off, thereby effectively reducing the off-state current of the thin film transistor. When the thin film transistor of the present invention is applied to a display device, the display contrast of the display device can be imp...

Embodiment 2

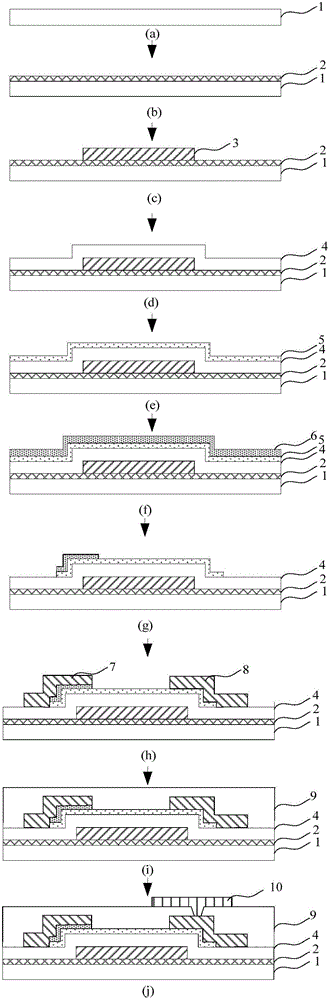

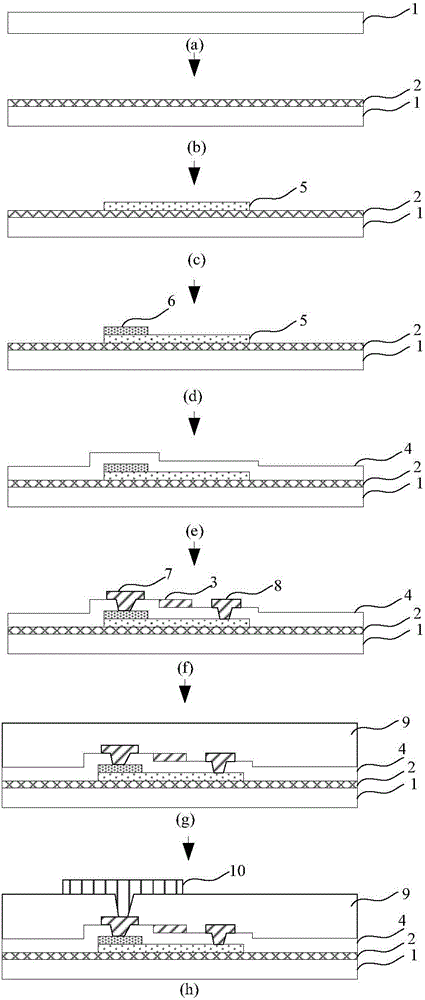

[0072] This embodiment provides a method for manufacturing a thin film transistor, including forming a gate, a gate insulating layer, a source, a drain, and an active layer on a substrate, and the method further includes:

[0073] A unidirectional conduction device is formed between the active layer and the drain, so that electrical signals are transmitted from the active layer to the drain through the unidirectional conduction device.

[0074] In this embodiment, a unidirectional conduction device is formed between the active layer and the drain of the thin film transistor. When the potential of the active layer is higher than the potential of the drain, the unidirectional conduction device is turned on; When the potential is lower than the potential of the drain, the unidirectional conduction device is cut off, thereby effectively reducing the off-state current of the thin film transistor. When the thin film transistor of the present invention is applied to a display device, ...

Embodiment 3

[0091] This embodiment provides an array substrate, including the thin film transistor mentioned above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com