X-ray sensor and manufacturing method thereof

A manufacturing method and sensor technology, which are applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as damage to the sensing unit, and achieve blocking damage, reducing optical interference, and high penetration. and the effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

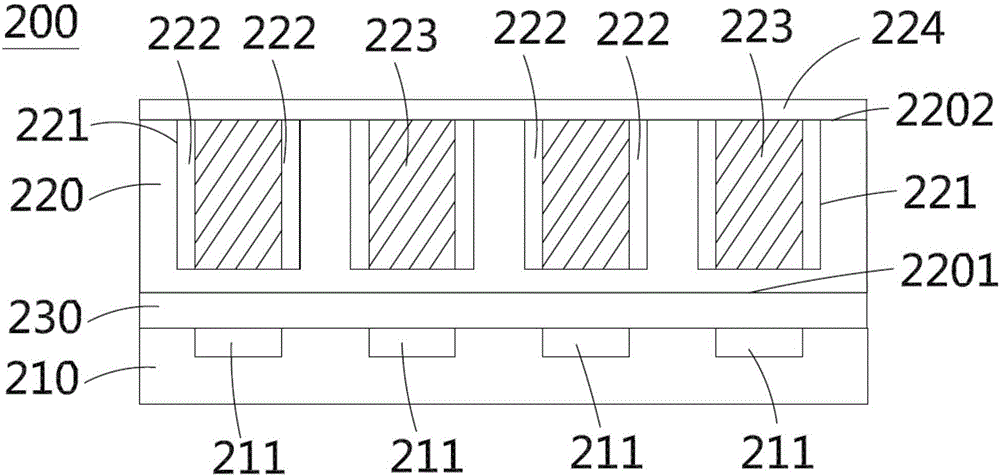

[0034] Please refer to figure 2 , figure 2 It is a schematic diagram of the X-ray sensor of the present invention. The X-ray sensor 200 includes a sensing substrate 210 and a lead glass substrate 220 . A plurality of sensing units 211 are disposed on the sensing substrate 210 .

[0035] The lead glass substrate 220 has a first surface 2201 and a second surface 2202 opposite to each other. The first surface 2201 is fixed on the sensing substrate 210. For example, in this embodiment, the X-ray sensor 200 further includes an adhesive layer 230, and the first surface 2201 can be fixed on the sensing substrate 210 through the adhesive layer 230. Of course , in other implementation manners, other fixing methods can also be used, as long as the first surface 2201 can be fixed on the sensing substrate 210 . The second surface 2202 of the lead glass substrate 220 has a plurality of grooves 221 corresponding to the plurality of sensing units 211 one-to-one.

[0036] The lead glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com