Integrated cylindrical power battery module and manufacturing method therefor

A technology for cylindrical batteries and power batteries, which is applied in secondary battery manufacturing, cylindrical case batteries/batteries, secondary batteries, etc. It can solve problems such as poor sealing performance, large temperature difference between air inlet and air outlet, and uneven heat dissipation , to achieve good heat dissipation uniformity, increase the number of charge and discharge, and overcome the effects of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

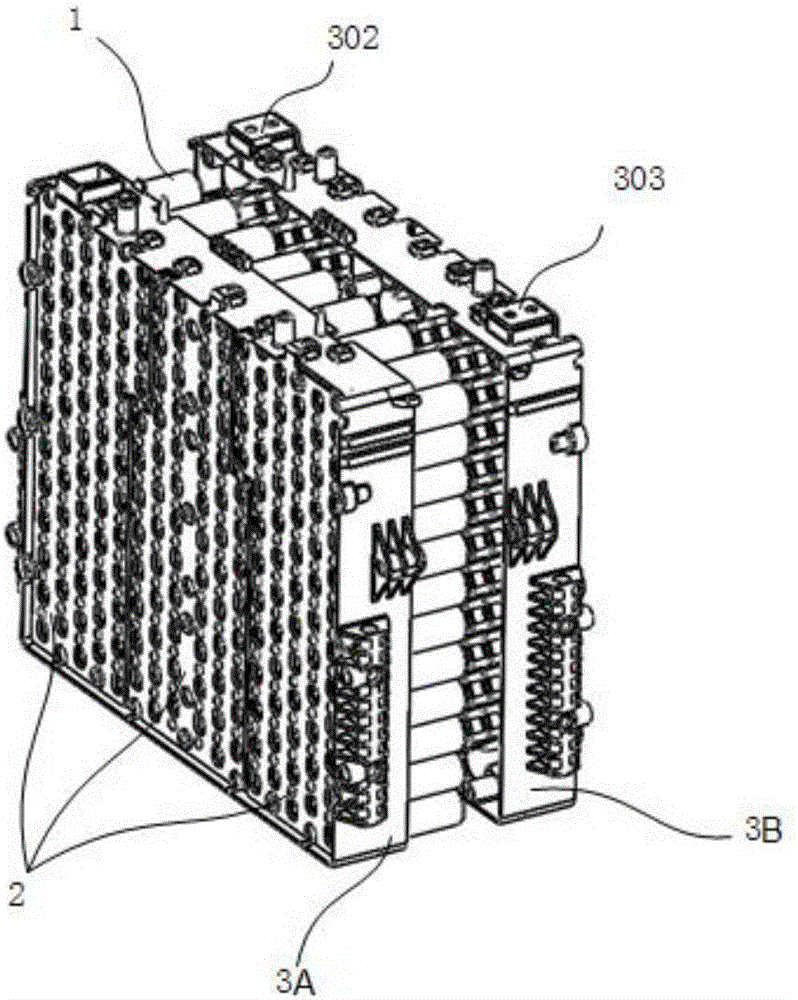

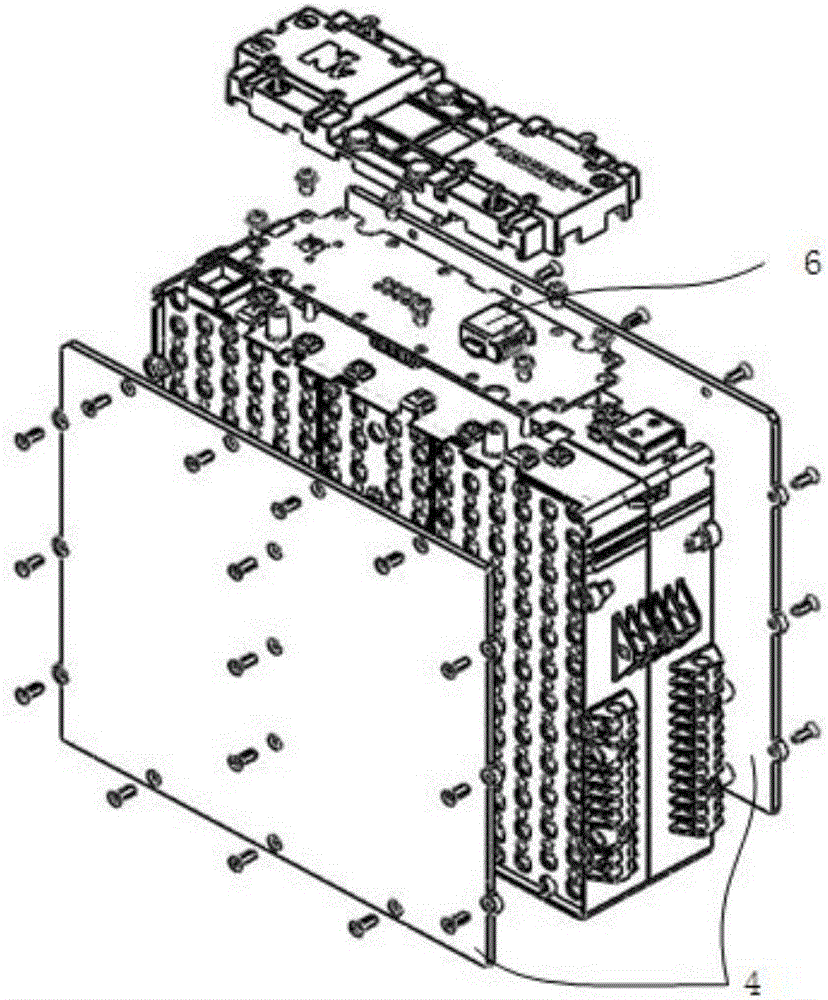

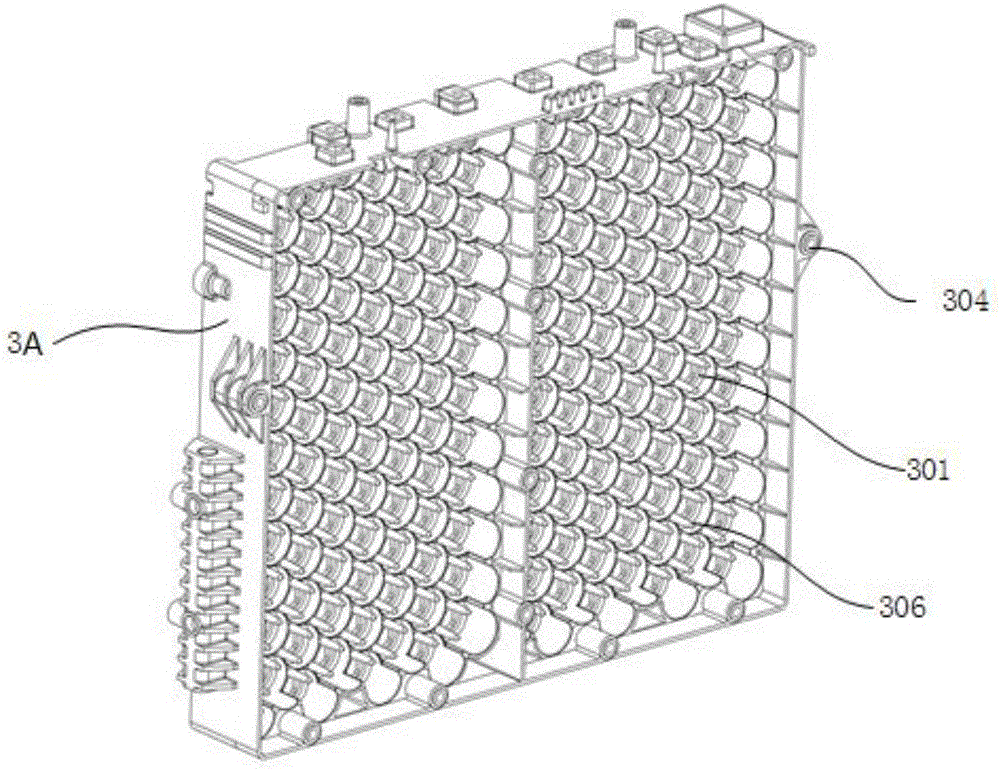

[0038] Such as Figures 1 to 3 As shown, the present invention provides an integrated cylindrical power battery module, including a plurality of cylindrical batteries 1, a plurality of jumpers 2, a housing for accommodating the cylindrical batteries, a thermal management module 4, a temperature acquisition module and a processor Module 6;

[0039] in,

[0040] The housing is composed of a first housing 3A and a second housing 3B, the first housing 3A and the second housing 3B have joint surfaces that match each other, the first housing 3A and the The second housing 3B is respectively provided with a plurality of one-to-one opposite installation holes 301, the first housing 3A and the second housing 3B are respectively provided with a plurality of said bridging pieces 2, said The bridging piece 2 on the first casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com