Electrode paste preparation method

A technology of electrode slurry and conductive agent, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve problems such as large surface area, poor dispersibility of nanoparticles, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

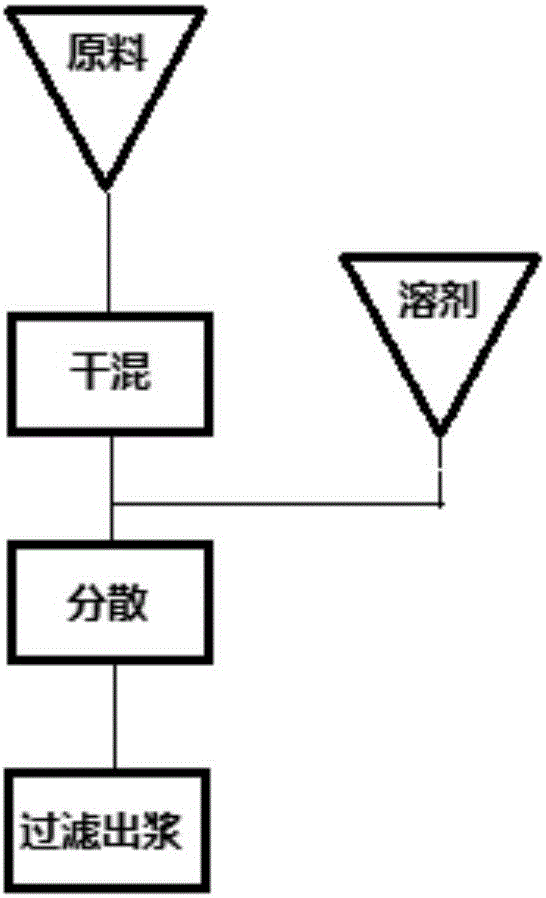

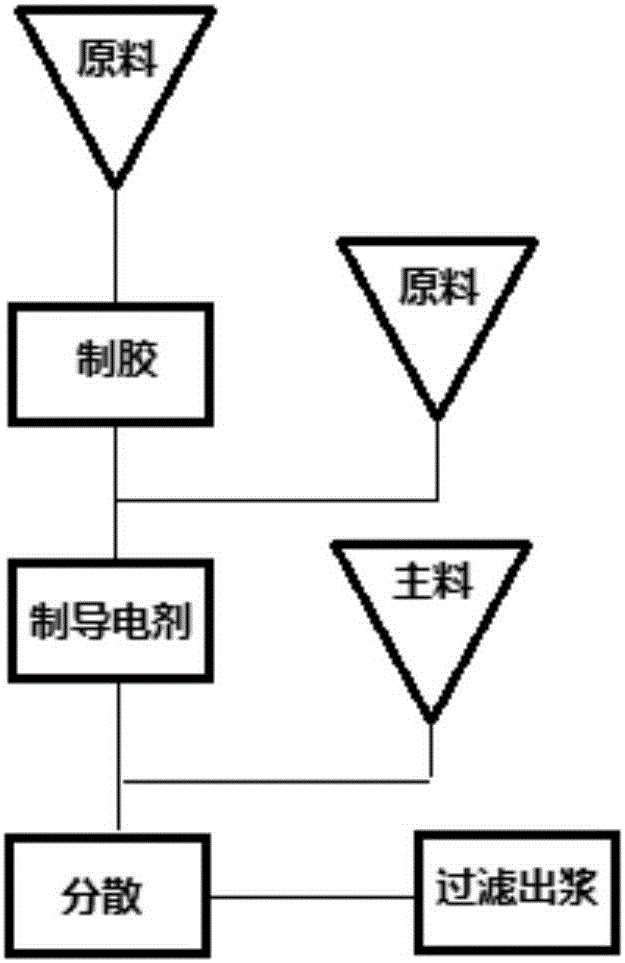

Method used

Image

Examples

Embodiment 1

[0088] 1. Preparation of cathode slurry

[0089] The formulation of the positive electrode slurry is shown in Table 1.

[0090] Table 1

[0091]

[0092] 1) Prepare positive electrode binder solution

[0093] The solid content of the positive electrode binder solution was 10%. PVDF was added to the solvent NMP twice. The stirring process and effect are shown in Table 2. The stirring temperature was 45° C. and it took about 4 hours to obtain the positive electrode binder solution.

[0094] Table 2

[0095]

[0096]

[0097] 2) Preparation of conductive agent solution

[0098] The preparation of the conductive agent solution is carried out substantially simultaneously with the preparation of the positive electrode binder solution. The conductive agent is mixed with the solvent NMP and then stirred. First, weigh the solvent NMP and add it to the stirring pot, then add the conductive agent twice, the first time to add SP type carbon black conductive agent, the second...

Embodiment 2

[0127] In the preparation method of the electrode slurry described in the present invention, it is also possible to add 10-60% of the binder solution or thickener solution after the conductive agent solution is prepared, stir evenly, and then add in batches active substance and remaining binder solution or thickener solution.

[0128] To prepare the positive electrode slurry in this example, first add 30% binder solution to the conductive agent solution. The specific stirring process is shown in Table 9. The stirring temperature is 25°C. After stirring evenly, add the active material and remaining binder solution. The preparation method of the binder solution is the same as in Example 1, and the addition method and stirring process of the active substance and the remaining binder solution are the same as in Example 1.

[0129] Table 9

[0130]

[0131] In Example 2, during the preparation of the electrode slurry, part of the binder solution is first added to the conductiv...

experiment example 1

[0141] The dispersion effect of experimental example 1 different preparation methods

[0142] After stirring the positive and negative electrode slurries obtained in Example 1 and Comparative Example 1, they were screened and coated to obtain positive and negative electrode sheets. Scanning electron microscopy was carried out on the positive and negative electrodes to investigate the effect of slurry stirring. The electron microscope model is FEIQuanta650F.

[0143] Depend on Figure 4 to Figure 7 It can be observed that the uniformity of the slurry obtained by using the preparation method of the present invention and the traditional preparation method is significantly different after being coated respectively, and the specific comparison results are shown in Table 12.

[0144] Table 12

[0145]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com