Rotary electric machine

A subgroup, laminate technology, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as high cost, and achieve the effect of improving cooling and good cooling possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

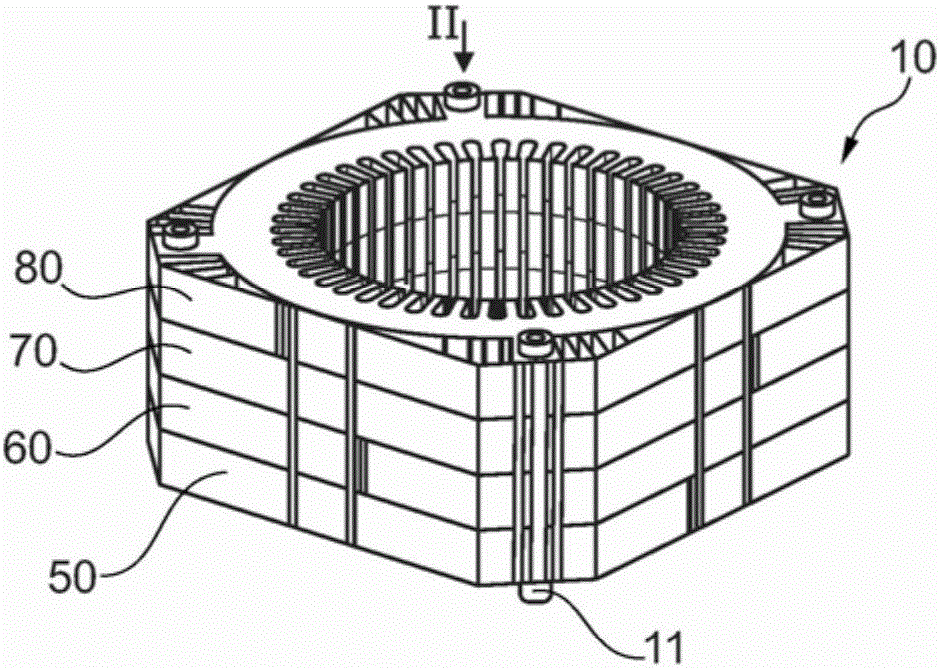

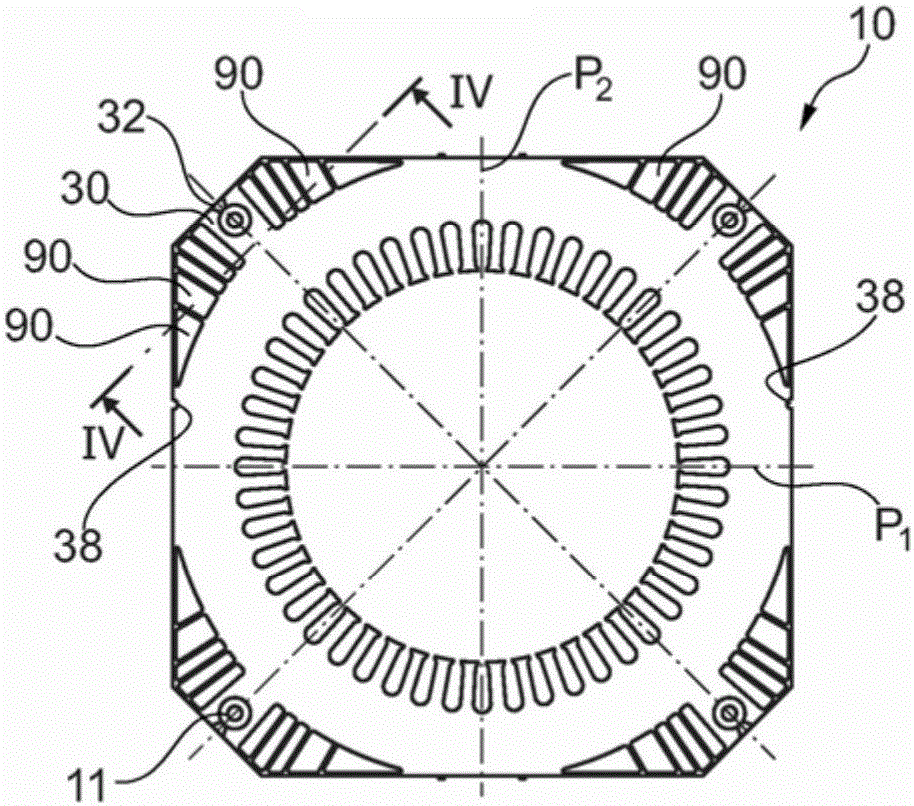

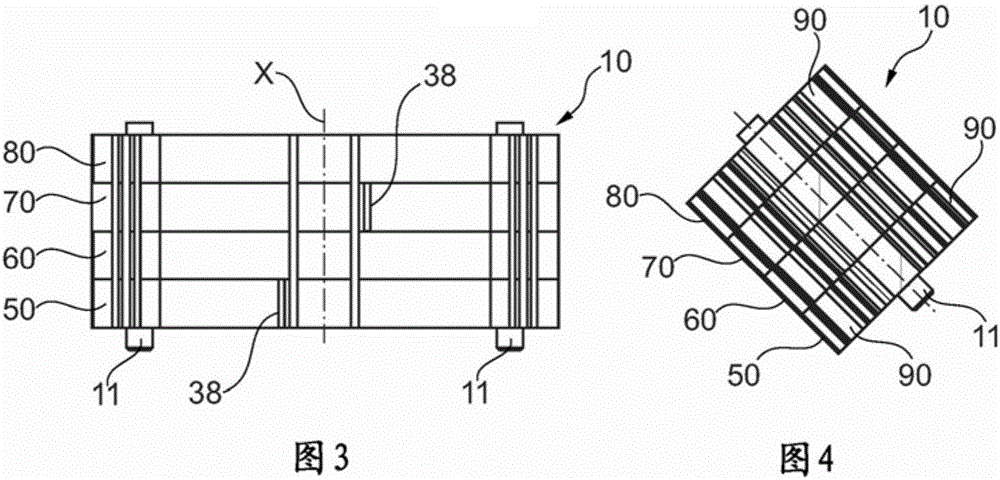

[0053] figure 1 One example of a stator lamination pack 10 of a rotating electric machine according to the invention is depicted to FIG. 4 . The rotating electric machine may be a synchronous or asynchronous permanent magnet or an alternator or electric motor. Figure 10 to Figure 12 An example of a complete motor 1 is depicted in .

[0054] The set 10 includes a plurality of superimposed magnetic laminations 20, one magnetic lamination in the plurality of superimposed magnetic laminations 20 Figure 5 are depicted separately in front view.

[0055] Each laminate 20 is made, for example, of magnetic steel covered on its opposite face by an electrically insulating varnish in a manner known per se.

[0056] In the example considered, the electric machine has an internal rotor, and each laminate 20 comprises a central opening 21 for passage of the rotor, into which an open slot 22 is cut into the laminate. and is intended to receive the electrical conductors of the stator win...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap