Mechanical seedling raising device for tomatoes

A seedling raising device and tomato technology, applied in the field of agricultural cultivation, can solve the problems of manual seeding, waste of human resources, etc., and achieve the effect of simple structure, convenient management of later seedling raising, and realization of industrialized rapid seeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the text of the description.

[0032] It should be understood that terms such as "having", "including" and "including" used herein do not equate the presence or addition of one or more other elements or combinations thereof.

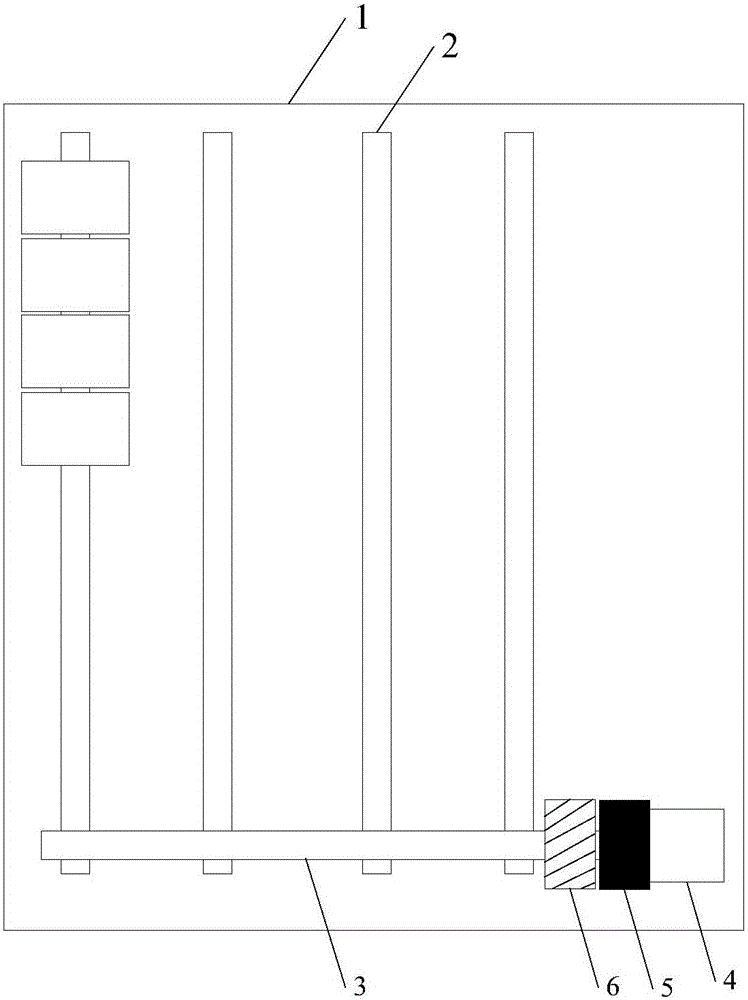

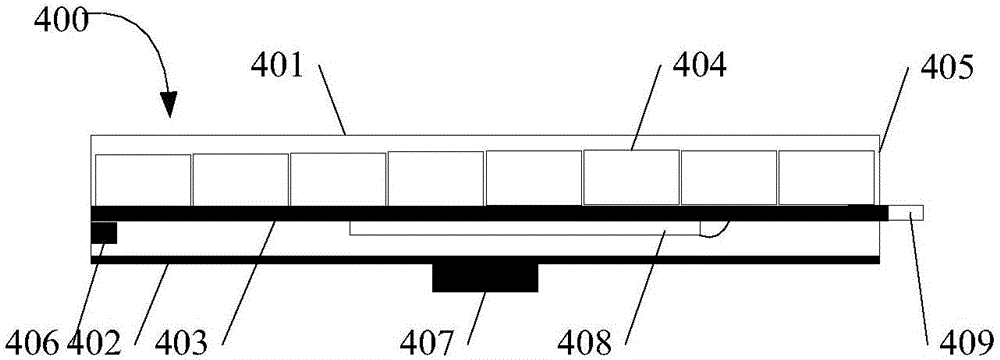

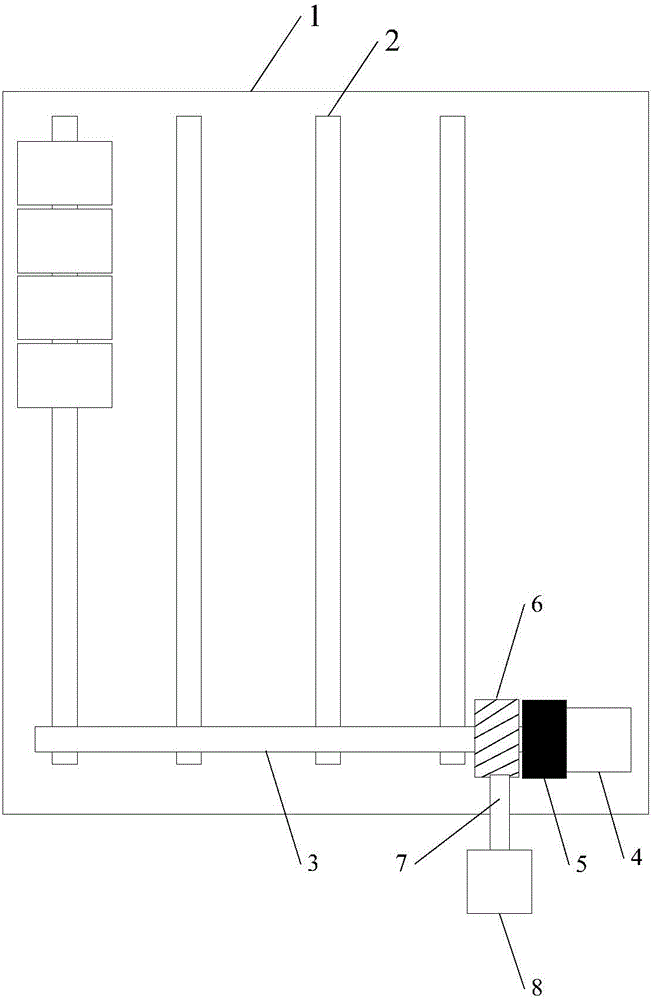

[0033] Such as figure 1 , 2 As shown, the present invention provides a mechanized tomato seedling raising device, which is characterized in that it comprises:

[0034] Planting shed 100;

[0035] The first guide rail is arranged in the planting shed. The first guide rail includes a plurality of rows of longitudinal guide rails 200 arranged in parallel with each other and a transverse guide rail 300 arranged vertically at one end of the longitudinal guide rail. The intersection of the transverse guide rail and the longitudinal guide rail Mutual conduction

[0036] The seedling bed 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com