Selenium absorption tower

A technology of absorption tower and selenium element, applied in gas treatment, membrane technology, separation of dispersed particles, etc., can solve the problems of lower dissolution rate, lower absorption efficiency, higher cost, etc., and achieve the effect of improving recovery efficiency and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

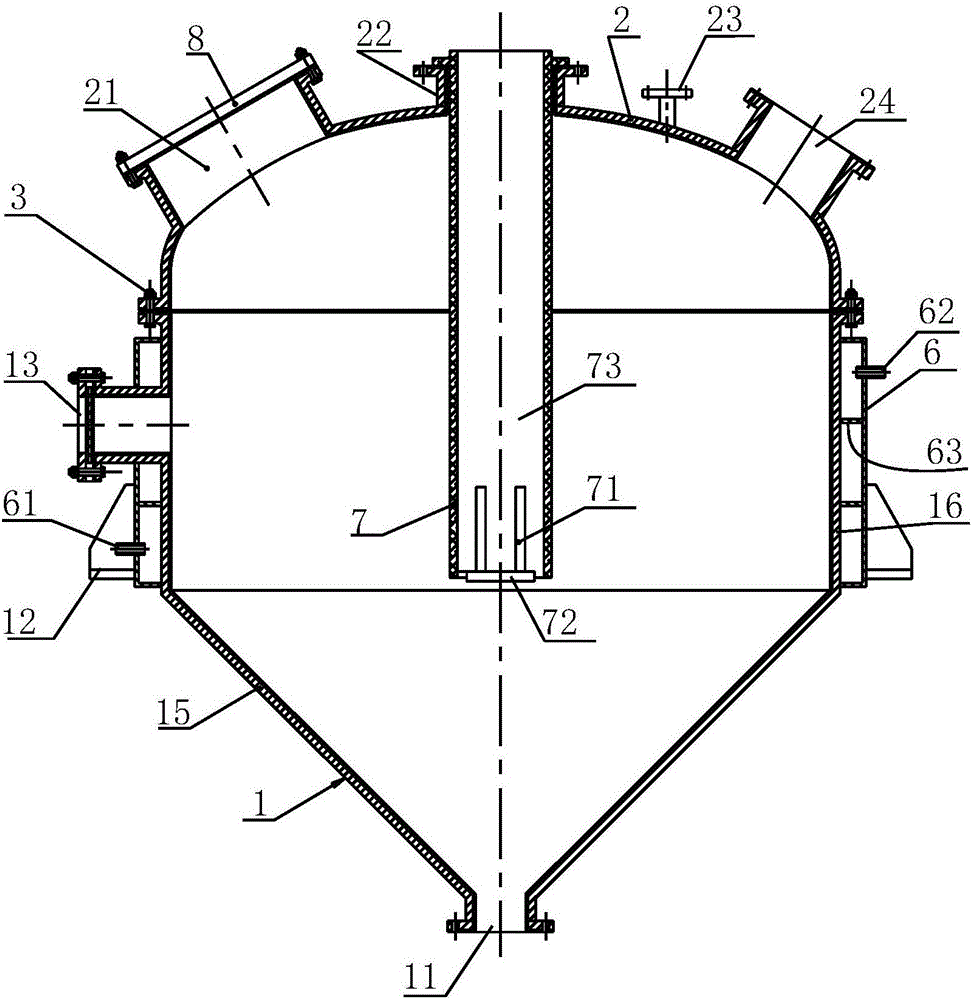

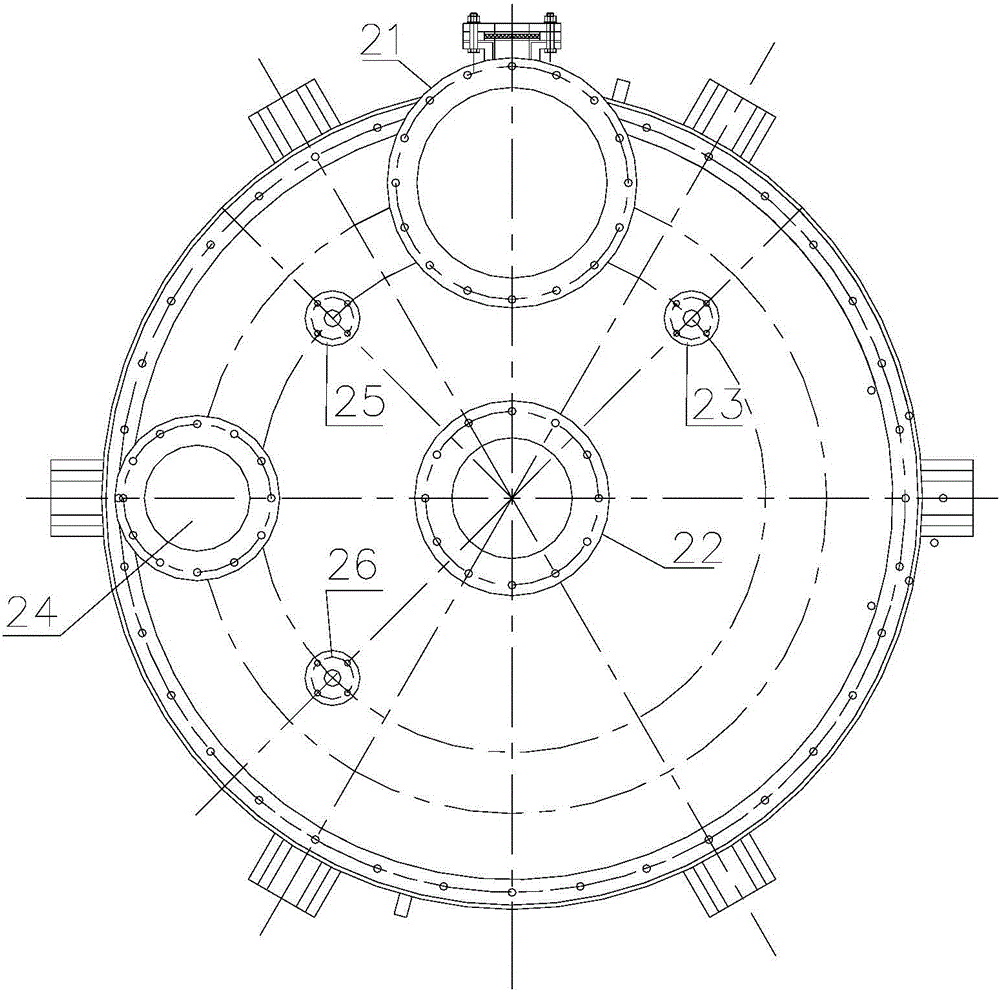

[0021] see figure 1 and figure 2 , a selenium element absorption tower, comprising a tower body 1 and a tower cover 2 fixedly connected to the upper end of the tower body, a feed hole 24 and an exhaust hole 22 are arranged on the tower cover 2, and a Insert pipe 7 in the tower, the lower end of the insert pipe 7 in the tower is provided with the air hole 71 that communicates with the inner chamber 73 of the insert pipe 7 in the tower, and the highest point of the above air hole 71 is lower than the liquid level line of the absorption liquid in the absorption tower. The outer wall of the tower body is provided with a cooling jacket 6 for circulating cooling liquid; the above-mentioned liquid level line refers to the contour line of the liquid level when the absorption liquid in the absorption tower reaches the specified filling capacity. Above-mentioned pore 71 has several, is offered on the side wall of the lower end of the intubation pipe in the tower, and arranges around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com