A kind of biochar composite material and preparation method thereof

A composite material, biochar technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems such as limited adsorption capacity, and achieve the effects of convenient operation, rich surface active groups, and huge specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of biochar composite material of the present invention:

[0032] The peeled stems of ramie were dried at room temperature, pulverized by a pulverizer and then ground, passed through a 100-mesh sieve, and a sodium humate solution with a mass concentration range of 5 g / L was prepared, and filtered after ultrasonication for 20 minutes to remove insoluble matter; 50 g of ramie stems After soaking the powder in 1000mL sodium humate solution with a mass concentration range of 5g / L for 1-5h, dry it at 80°C, put it into a tube furnace for pyrolysis, feed nitrogen at a flow rate of 100mL / min, and Raise the temperature to 500°C at a speed of 1 / min, keep pyrolysis for 2 hours after the temperature rises to 500°C, and cool the obtained product to room temperature under the condition of continuing to maintain nitrogen flow, then repeatedly wash with deionized water, and then pass through 200 sieves after grinding , and dried at 70°C for 5 hours to prepar...

Embodiment 2

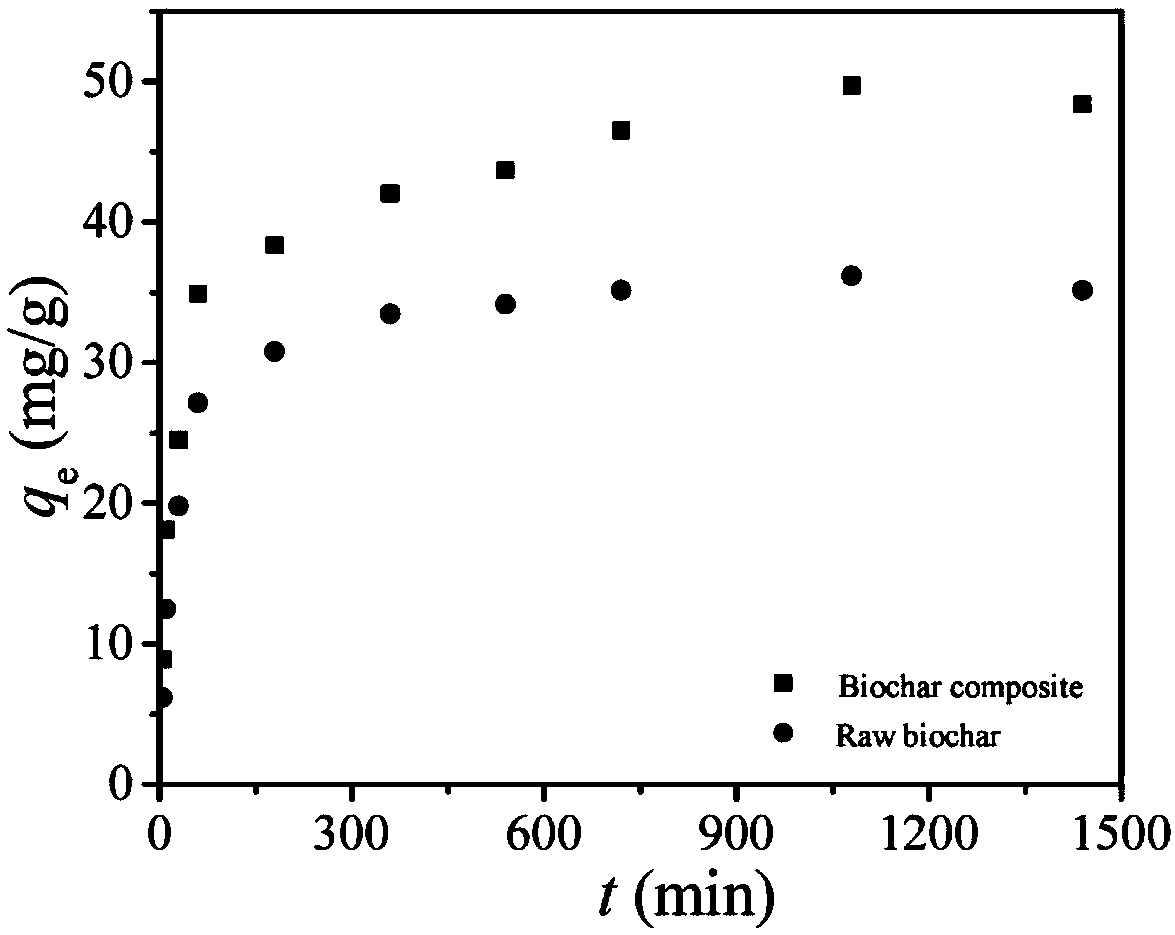

[0036] The biochar composite material of the present invention is used in the field of water treatment to remove heavy metal ions in water, comprising the following steps:

[0037] Get ten volumes and be 50mL, the initial concentration is the hexavalent chromium wastewater sample to be treated of 100mg / L, adjust the pH value to 3 with nitric acid or sodium hydroxide, add the biochar magnetic composite material that embodiment 1 makes to wastewater sample In this process, the amount added per liter of waste water is 2g based on the weight of the biochar composite material. The reactor is placed in a constant temperature water bath shaking box with a rotation speed of 150rpm, and the temperature is kept at 30°C. Shake for 5min, 10min, 30min, 1h, 3h , After 6h, 9h, 12h, 18h, and 24h, the biochar composite material is separated from the solution to complete the treatment of hexavalent chromium wastewater. The concentration of the remaining hexavalent chromium in the solution is me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com