Rice threshing device

A threshing device and technology for paddy, applied in grain hulling, grain processing, grain pod removal, etc., can solve the problems of agricultural production waste, energy waste, waste, etc., and achieve the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

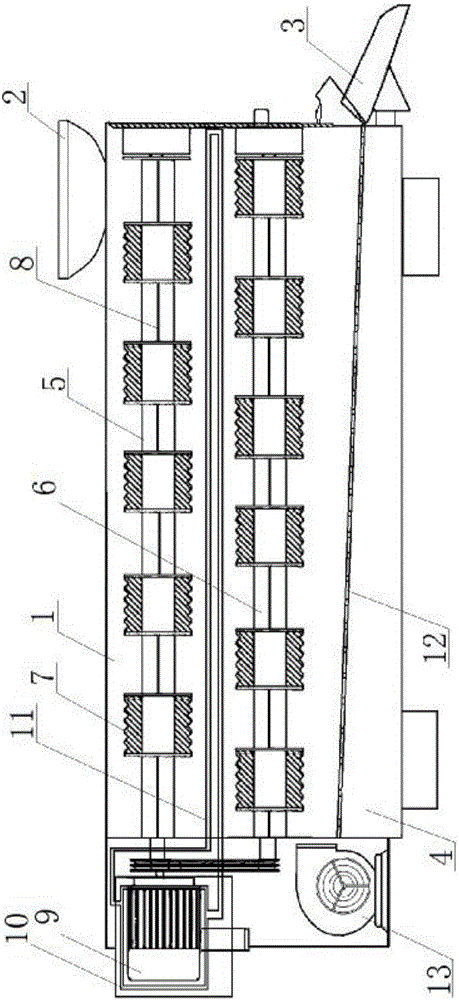

[0016] Such as figure 1 As shown, a rice threshing device includes a device housing 1, the rear portion of the device housing 1 is provided with a rice inlet 2 and a rice bran outlet 3, wherein the rice inlet 2 is arranged above the rear portion of the device housing 1, and the rice The bran outlet 3 is arranged under the rear part of the device housing 1, the lower part of the device housing 1 is provided with a brown rice recovery bin 4, the brown rice recovery bin 4 is used to recover the threshed brown rice, and the inside of the device housing 1 is provided with a threshing rotary Bearing, the outer surface of the threshing rotary bearing is equipped with a cutter head 7, and the inside of the threshing rotary bearing is equipped with a heating rod 8, and the threshing rotary bearing is made of heat-conducting material, so that the heating rod 8 can transfer heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com