A fast-installation center positioning circumferentially symmetrical anode plate assembly process and device

A technology of central positioning and assembling device, applied in the field of air pollutant control, can solve the problems of low effective utilization rate of dust collection area, large amount of on-site splicing and installation works, encroaching on effective use area, etc., to achieve broad market promotion and application prospects, increase The utilization rate of dust collection area, the effect of reducing investment cost and assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

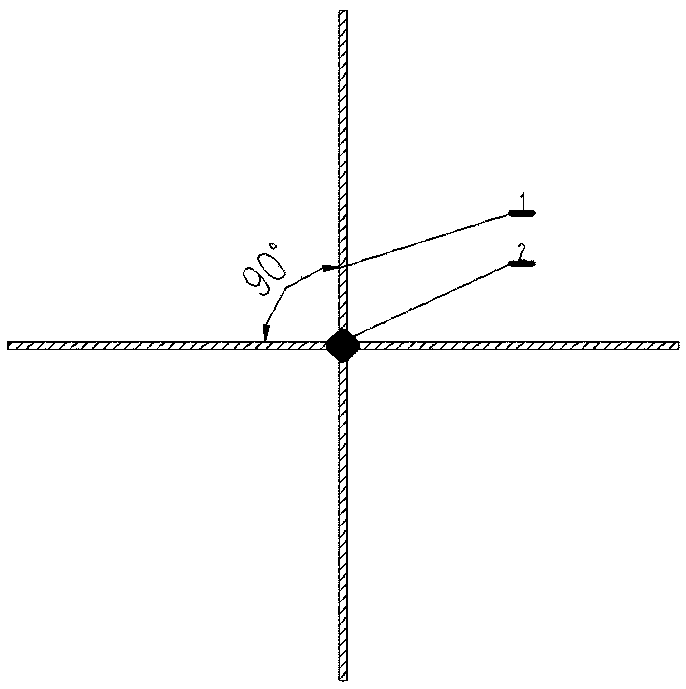

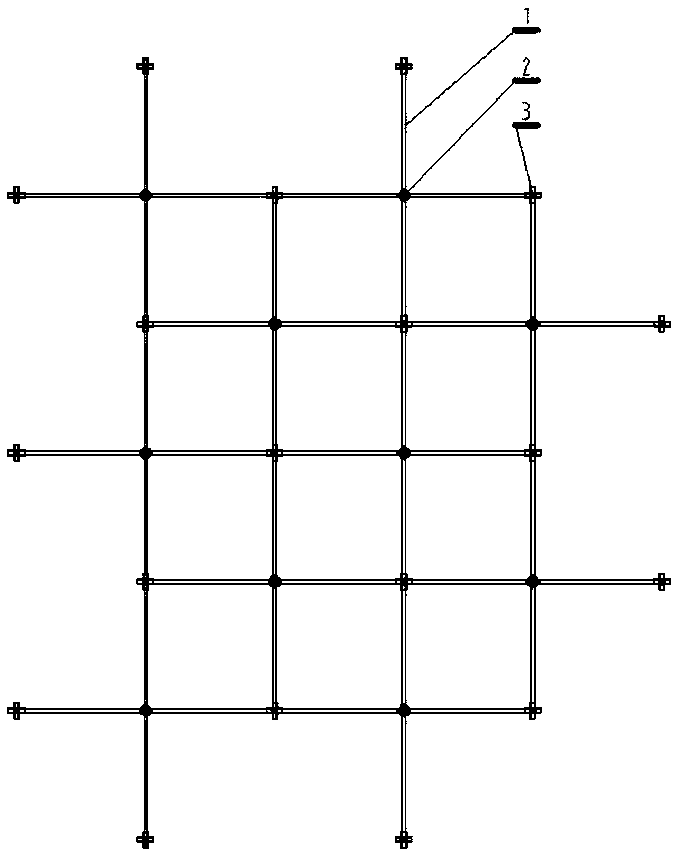

[0035] like Figure 11 , Figure 14 , Figure 16 As shown, the quick-loading center positioning circumferentially symmetrical anode plate assembly device includes a plurality of anode plate assembly units, and each anode plate assembly unit includes a positioning rod 2, which is evenly arranged in a circle along the axial direction of the positioning rod 2 and connected to it. The four anode plates 1 distributed at 90 degrees (such as figure 1 shown), and the anode plates of adjacent anode plate assembly units are connected by four-corner C-shaped buckles 3-1 (such as Figure 4 shown), ⊥ regular triangle C-shaped connection buckle 3-6 (such as Figure 9 shown) and right-angled C-type connection buckle 3-4 (such as Figure 7 As shown), the four-corner C-shaped connecting buckle is a "cross"-shaped connecting plate, and a C-shaped groove is distributed on each of the four ends of the connecting plate. The ⊥ regular triangle C-shaped The connecting buckle includes a "⊥"-shap...

Embodiment 2

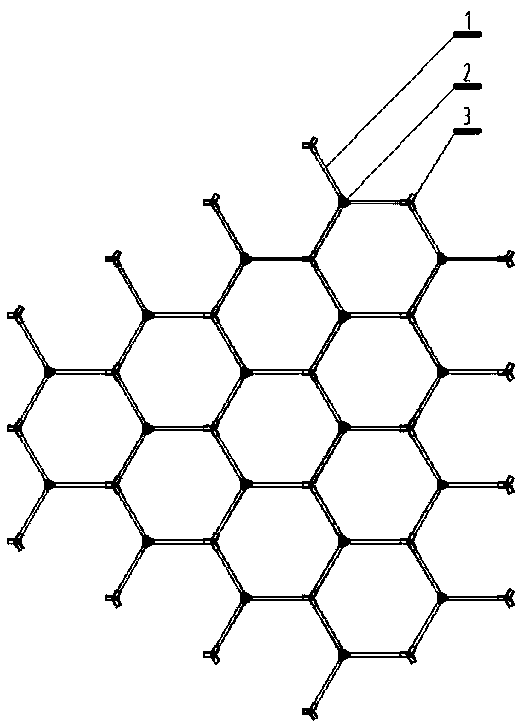

[0037] like Figure 10 , Figure 13 , Figure 15 As shown, the quick-loading center positioning circumferentially symmetrical anode plate assembly device includes a plurality of anode plate assembly units, each anode plate assembly unit includes a positioning rod 2, and a circle of connecting rods is evenly arranged along the axial direction of the positioning rod. Three anode plates 1 distributed at 120 degrees (such as figure 2 shown), and the anode plates of adjacent anode plate assembly units are connected by a regular triangle C-shaped buckle 3-2 (such as Figure 5 shown) and 120 ° two-angle C-type connection buckle 3-5 (such as Figure 8 As shown), the regular triangle C-shaped connecting buckle is a connecting plate distributed in the shape of an "equal triangle", and a C-shaped groove is distributed on each of the three ends of the connecting plate, and the 120° The two-corner C-shaped connection buckle is a connecting plate bent at 120 degrees, and a C-shaped gro...

Embodiment 3

[0039] like Figure 12 As shown, the quick-loading center positioning circumferentially symmetrical anode plate assembly device includes a plurality of anode plate assembly units, and each anode plate assembly unit includes a positioning rod. An anode plate distributed at 180 degrees (such as image 3 shown), and the anode plates of adjacent anode plate assembly units are connected by a 180° two-angle C-type buckle 3-3 (such as Image 6 As shown), the 180° two-angle C-shaped connecting buckle is a substantially rectangular connecting plate, and two symmetrically arranged C-shaped grooves are arranged on the connecting plate. The C-shaped concave The groove is used for clamping the anode plate.

[0040] Further, the equivalent diameter of the positioning rod is 25-40 mm; the cross-sectional shape of the positioning rod is a regular figure such as a triangle, a quadrangle or a circle.

[0041] Further, the width of the anode plate is 180-460 mm, the thickness is 1-4 mm, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com