Sand core assembling clamp for removable-flask molding and using method of sand core assembling clamp

A boxless molding and sand core technology, which is applied to cores, manufacturing tools, casting and molding equipment, etc., can solve the problems of difficult quality control and complicated operation process, and achieve the effects of easy material acquisition, low storage cost, and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

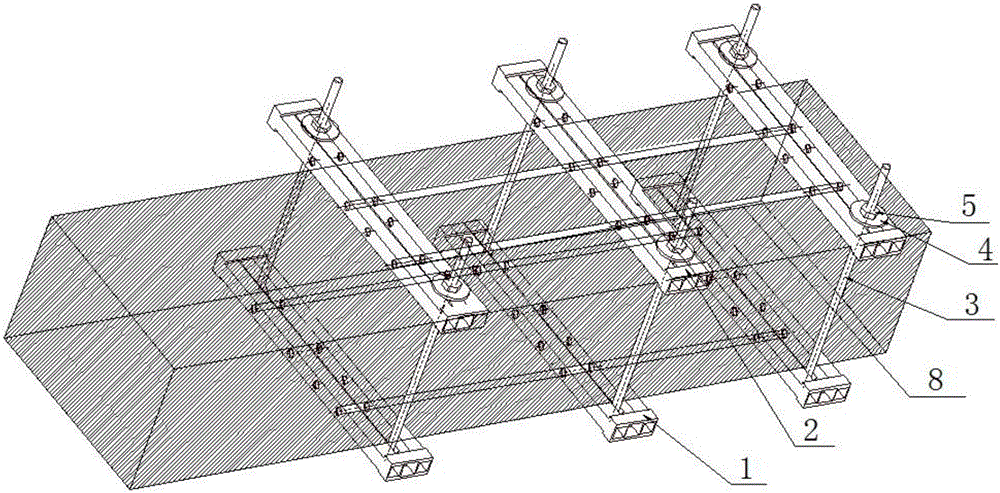

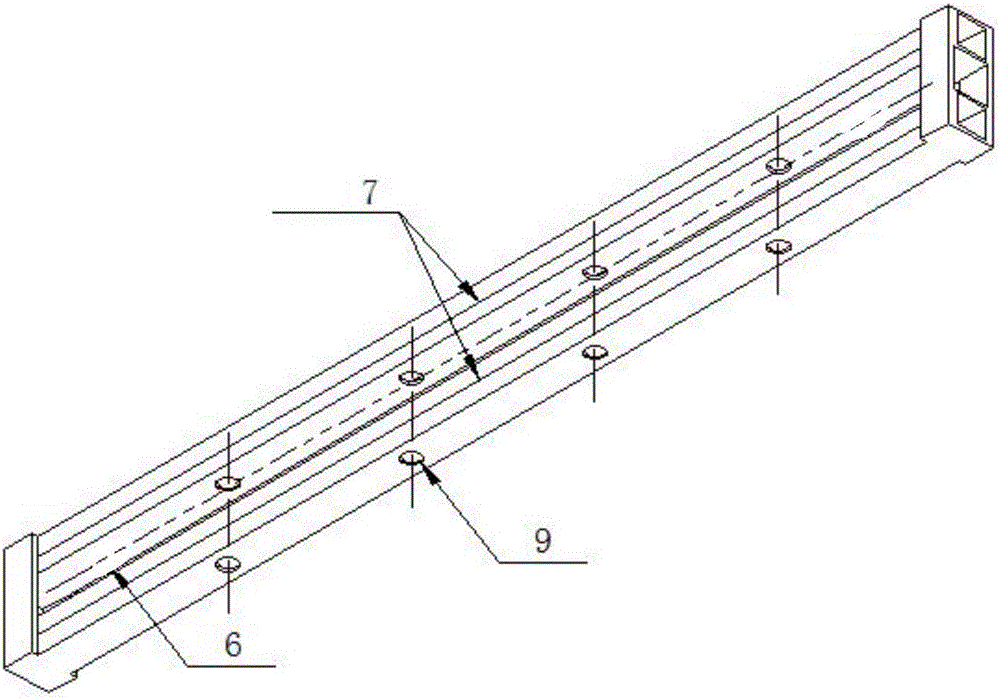

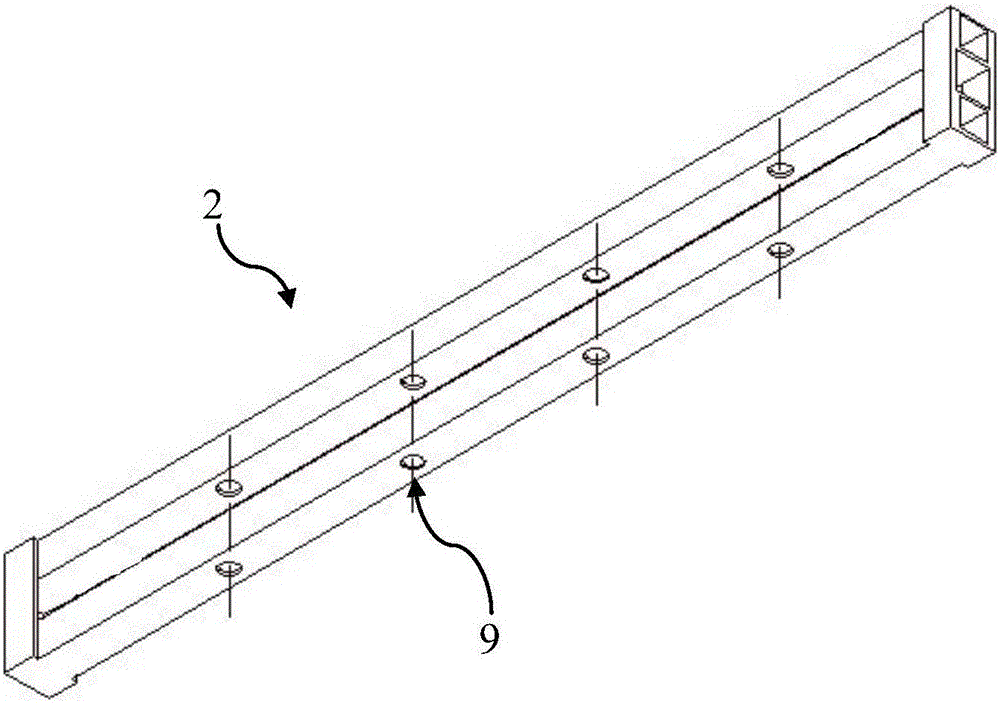

[0031] The solution of the present invention will be described below in conjunction with the accompanying drawings.

[0032] refer to Figure 1 to Figure 6 , shows a sand core assembly jig for boxless molding according to the present invention, which includes at least two sets of jig subassemblies. The fixture subassembly includes an assembly base plate 1 and an assembly cover plate 2, each of which includes a pair of square steel pipes arranged in parallel, and the pair of square steel pipes are spaced apart by a first distance and at the ends The upper and lower sides of the place are welded together by connecting steel plates, thereby defining a first gap between the pair of square steel pipes. The clip subassembly also includes four spacers 4 formed by welding a clip nut 5 at the center of a circular steel plate with a hole, the diameter of which is equal to or greater than that of the clip. The diameter of the threaded hole of clamping nut 5, so as not to interfere with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com