Online ladle safety residual thickness marking method and corresponding ladle

A technology of ladle and steel shell, applied in the online ladle safety residual thickness marking method and the corresponding ladle field, can solve the problem of difficulty in online measurement of ladle safety residual thickness, avoid major safety accidents, reduce misjudgment, and save refractory material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

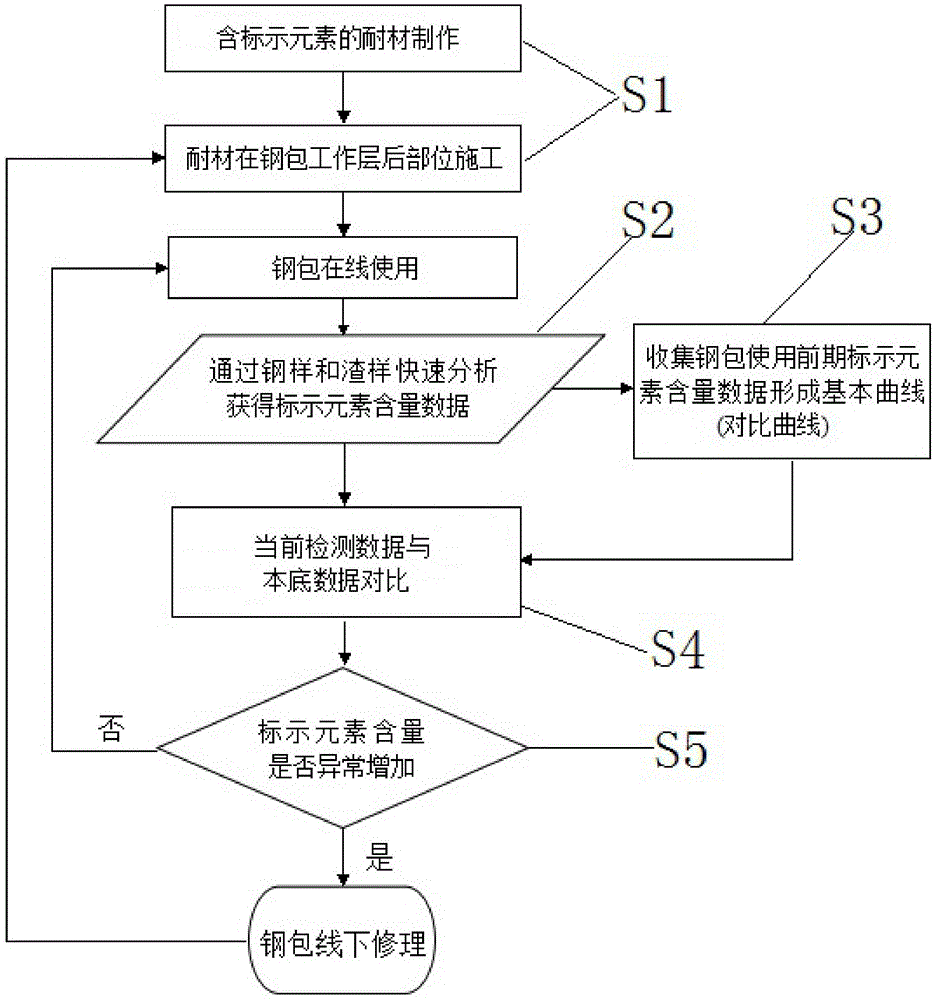

[0036] Make alabaster bricks containing 2% barium oxide with a thickness of 40mm, and at the same time thin the refractory material of the permanent layer of the entire ladle by 40mm, complete the masonry construction of the ladle, and put it on-line for use. In use, each furnace detects the content of barium in molten steel and slag samples, and compares it with the background statistical data to obtain Figure 5 The monitoring data graph of the marked elements is shown, if the content of the marked elements increases abnormally, the ladle will be taken off-line for repair.

[0037] Figure 5 The basic curve shows that the barium element fluctuates between 1-6ppm. In the 85th furnace, the barium element in the molten steel suddenly rises to 23ppm. The ladle is immediately checked off the production line, and abnormal erosion is found at the slag line, and the part is repaired immediately.

Embodiment 2

[0039] Clay bricks containing 5% barium oxide are made with a thickness of 20mm. At the same time, the refractory material of the permanent layer of the entire ladle is thinned by 20mm, and the ladle masonry construction is completed and put into use. In use, each furnace detects the content of barium in molten steel and slag samples, and compares it with the background statistical data to obtain Image 6The monitoring data graph of the marked elements is shown, if the content of the marked elements increases abnormally, the ladle will be taken off-line for repair.

[0040] Image 6 The basic curve shows that the barium element fluctuates between 2 and 10ppm. In the 75th furnace, the barium element in the molten steel suddenly rises to 27ppm. The ladle is immediately checked off the assembly line and found to be abnormally eroded in the impact zone at the bottom, and the part is repaired immediately.

Embodiment 3

[0042] Make alabaster bricks containing 3.5% barium oxide with a thickness of 30mm, and at the same time thin the refractory material of the permanent layer of the entire ladle by 35mm, complete the masonry construction of the ladle, and put it into use. In use, each furnace detects the content of barium in molten steel and slag samples, and compares it with the background statistical data to obtain Figure 7 The monitoring data graph of the marked elements is shown, if the content of the marked elements increases abnormally, the ladle will be taken off-line for repair.

[0043] Figure 7 The basic curve shows that the barium element fluctuates between 3 and 9ppm. In the 90th furnace, the barium element in the molten steel suddenly rises to 29ppm. The ladle is immediately checked off the production line, and the slag line under the cladding wall is found to be abnormally eroded, and the part is repaired immediately.

[0044] To sum up, the present invention can effectively mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com