Deep-hole drill with guide block

A technology of guide block and deep hole drilling, which is applied in the direction of drilling/drilling equipment, drill repairing, drilling tool accessories, etc. It can solve the problems of poor cutting stability, short service life, and poor use effect, and achieve convenient cooling and use The effect of long life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

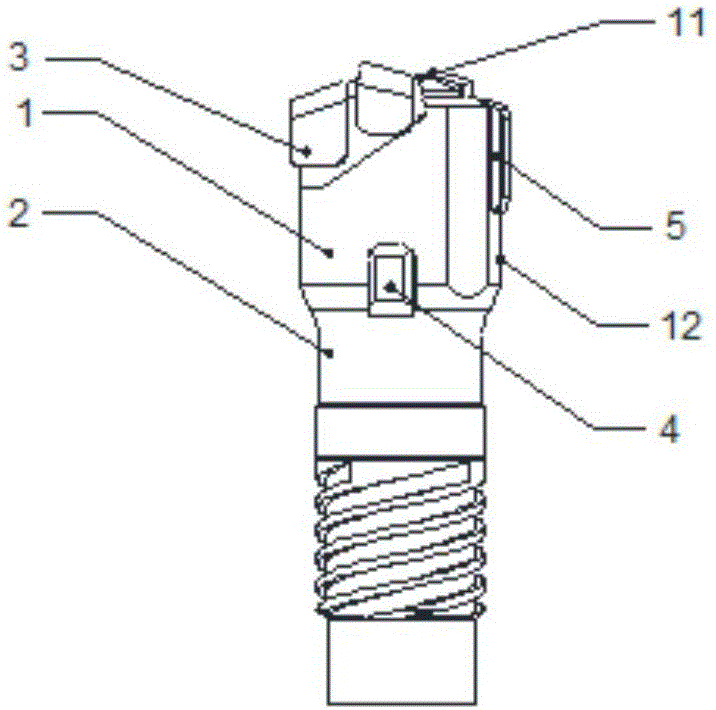

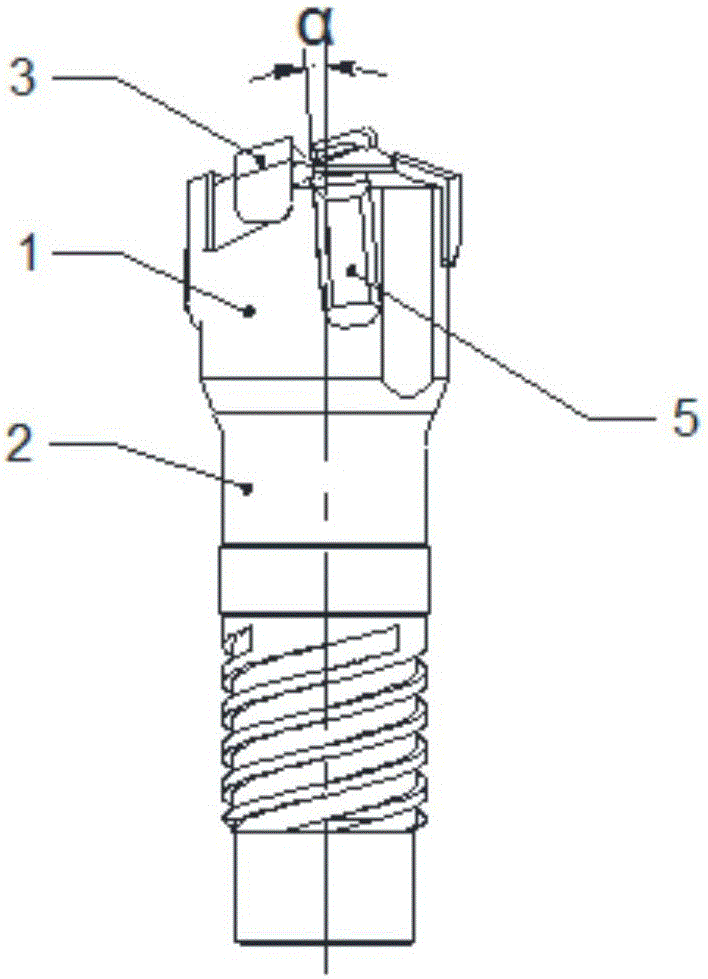

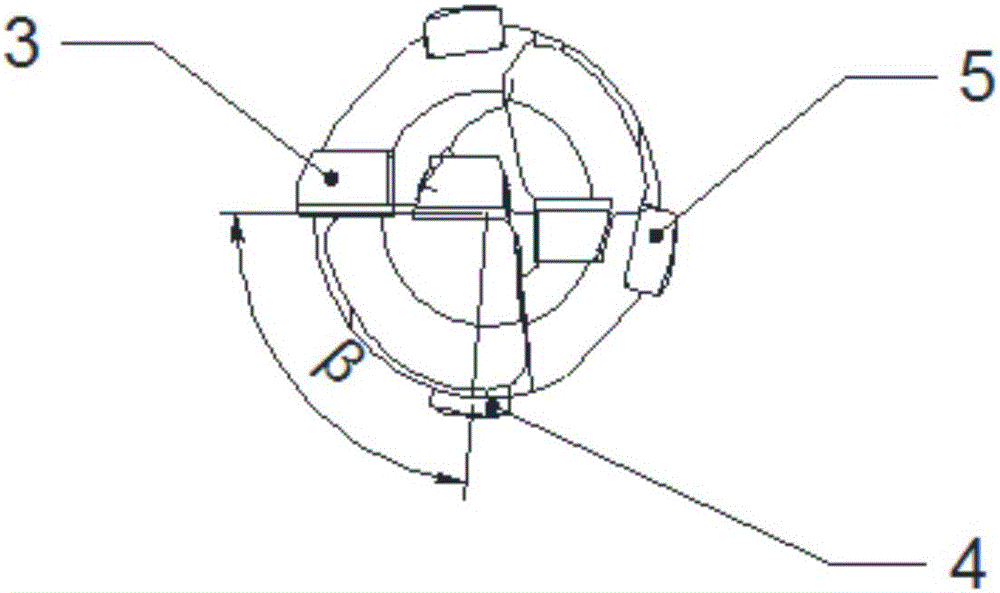

[0027] This embodiment provides a deep hole drill with a guide block, as attached figure 1 Shown, comprise cutter body 1 and the handle of a knife 2 that cutter body 1 is connected, cutter body 1 is cylindrical and comprises cylindrical bottom surface 11 and cylindrical side 12, and blade 3 is installed on the cylindrical bottom surface 11 of cutter body 1, and cutter body A guide block one 4 and two guide block two 5 are fixed on the cylinder side 12 of 1, the guide block one 4 is arranged on the cylinder side 12 and is close to the connecting portion between the cutter body 1 and the handle 3, and the guide block two 5 is a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap