Numerical control lathe

A technology for CNC lathes and machine tool spindles, which is applied in the field of CNC lathes, can solve problems such as bearing life that affects the machining quality of workpieces, inaccurate installation positions, poor accuracy and stability, and achieves the effect of eliminating potential safety hazards, easy processing, and ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

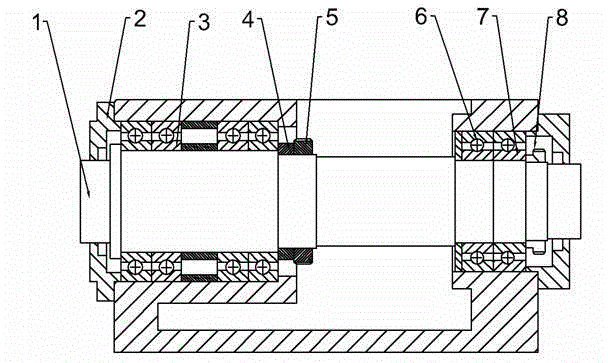

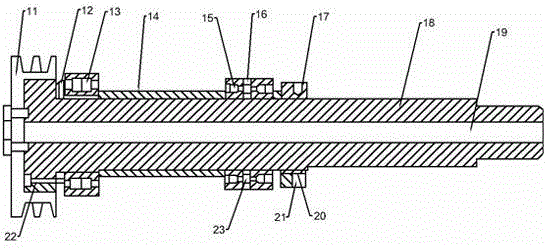

[0016] see Figure 1-2 , a numerically controlled lathe, comprising a workbench, on which a main shaft structure and a processing structure are arranged, and the main shaft structure comprises a machine tool main shaft 1, on which a first angular contact ball bearing 3 and a second angular contact ball bearing 3 are mounted. Ball bearing 6, the outer side of the first angular contact ball bearing 3 is provided with a flange 2, the inner side of the first angular contact ball bearing 3 is provided with a first nut 5 through the first adjusting pad 4, and the outer side of the second angular contact ball bearing 6 is passed through The second adjustment pad 7 is provided with a second nut 8; the machine tool spindle 1 includes a main shaft body 18, a liquid pipe 19 is arranged in the main shaft body 18, a third nut 17 is arranged above the main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com