Wear-resisting cigarette film and preparation method thereof

A technology of cigarette film and thin film, which is applied in the field of wear-resistant cigarette film and its preparation, can solve the problems of unclear cigarette label patterns, not being able to withstand grinding, whitening and fogging, etc., to improve aesthetics, reduce losses, Effect of increasing surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

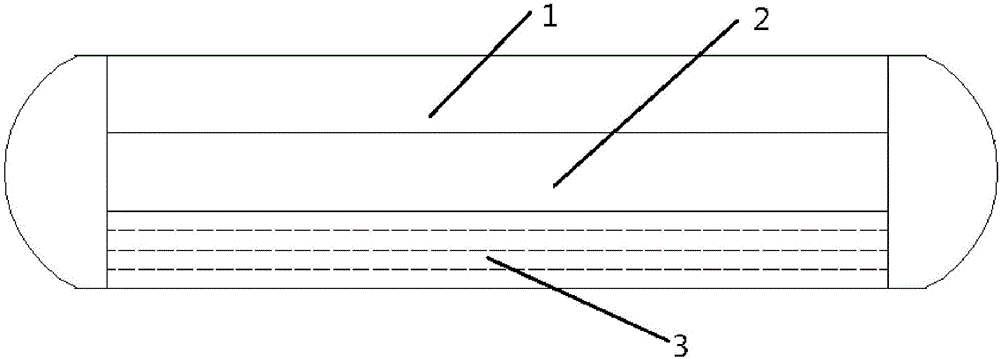

Image

Examples

preparation example Construction

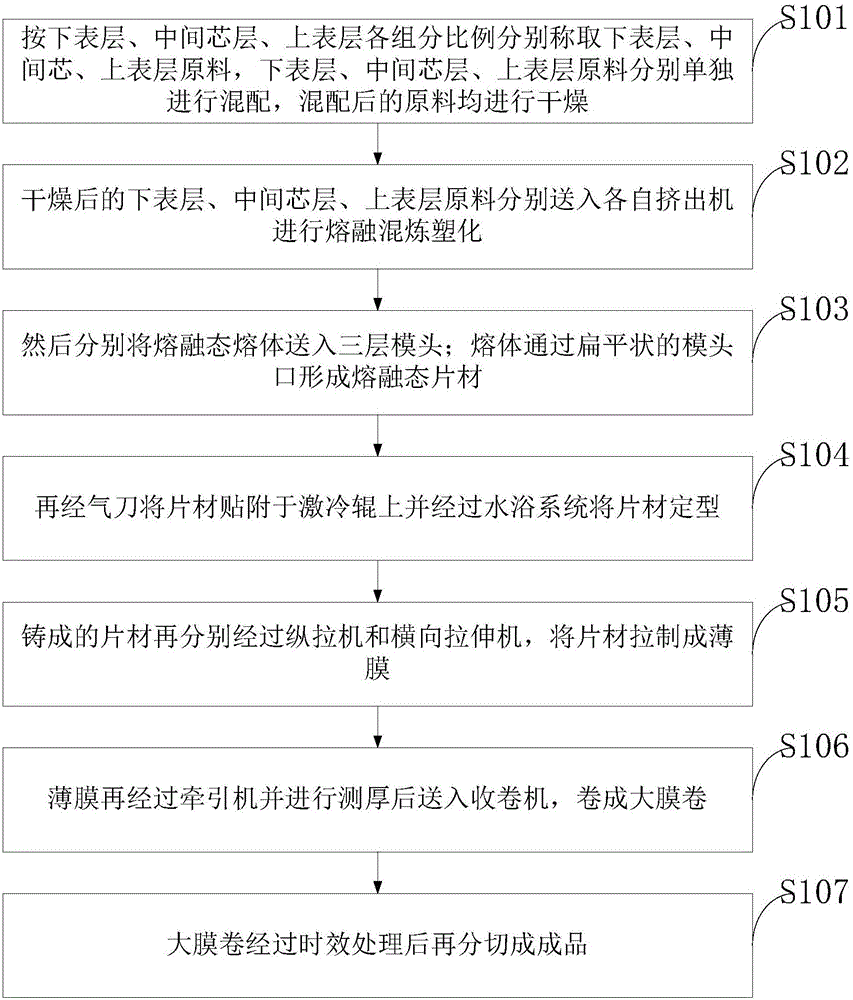

[0037] like figure 2 Shown: the preparation method of the wear-resisting smoke film that the embodiment of the present invention provides comprises the following steps:

[0038] S101: Weigh the raw materials of the lower surface layer, the middle core layer, and the upper surface layer according to the component ratios of the lower surface layer, the middle core layer, and the upper surface layer, respectively, and mix the lower surface layer, the middle core layer, and the upper surface layer raw materials separately, and the raw materials after mixing are dried;

[0039] S102: the lower surface layer after drying, the middle core layer, and the upper surface layer raw materials are respectively sent into respective extruders for melting, kneading and plasticization;

[0040] S103: Then the molten state melt is sent into the three-layer die head respectively; The melt forms a molten state sheet through the flat die head mouth;

[0041] S104: the sheet is attached to the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com