Bottle arrangement device for special-shaped soy sauce bottles

A bottle unscrambler, soy sauce technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of irregular arrangement of bottles, increased production cost, leakage of production date, etc., and achieves simple structure, convenient operation and low manufacturing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

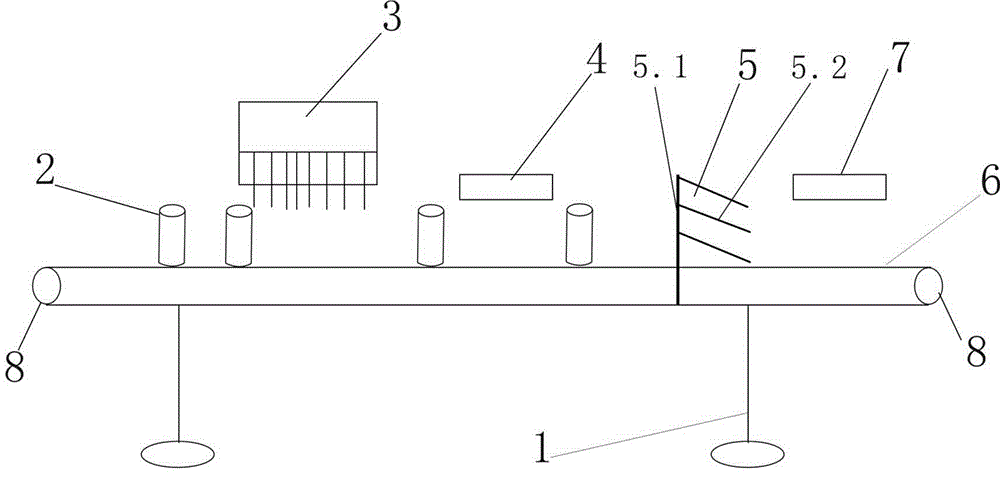

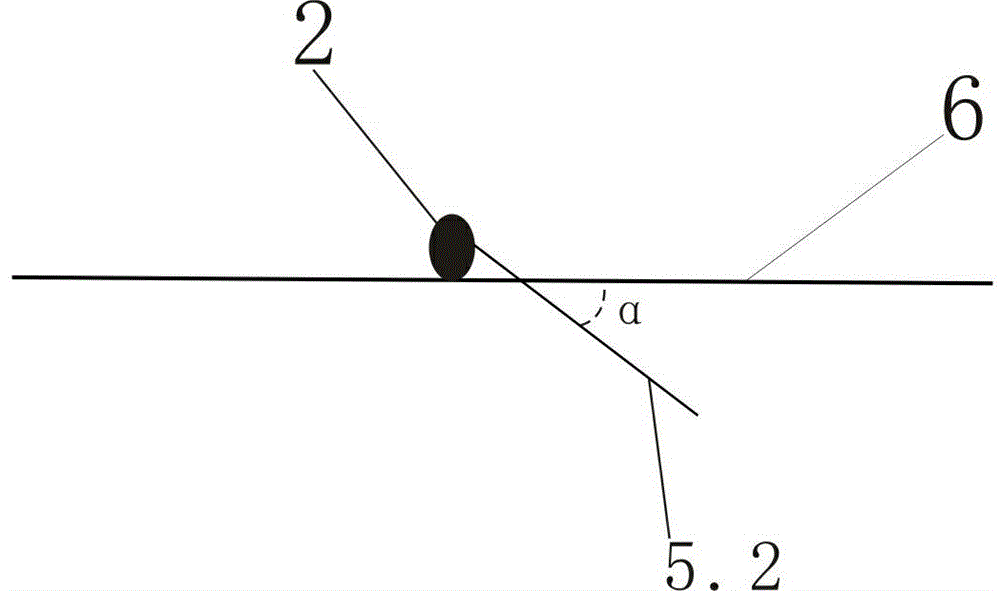

[0018] Such as figure 1 , figure 2 As shown, a bottle unscrambling device for special-shaped soy sauce bottles includes a frame 1, a conveyor belt 6 is installed on the frame 1, and a filling machine 3, a capping machine 4, a fork 5, The inkjet printer 7 and the special-shaped soy sauce bottle 2 are located on the conveyor belt 6. The special-shaped soy sauce bottle 2 is driven by the conveyor belt 6 and passes through the filling machine 3, the capping machine 4, the fork 5, and the inkjet printer 7 in sequence.

[0019] The filling machine 3 is an 8-head linear filling machine, which is used for quantitative hot filling of soy sauce in the special-shaped soy sauce bottle 2 .

[0020] The capping machine 4 mainly presses the bottle cap onto the special-shaped soy sauce bottle 2 by extrusion through the chain plate capping machine.

[0021] The inkjet printer 7 is a KN500 inkjet printer, which is used for inkjet coding.

[0022] The conveyor belt 6 is a stainless steel con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com