A kind of sulfonic acid production waste liquid modified aminobenzenesulfonic acid series high-efficiency water reducer

An aminobenzenesulfonic acid-based, high-efficiency water reducer technology, applied in the field of water reducer production, can solve the problems of high production cost, easy bleeding, low application level, etc., and achieve good product workability, no three wastes discharge, Reducing and Bleeding Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

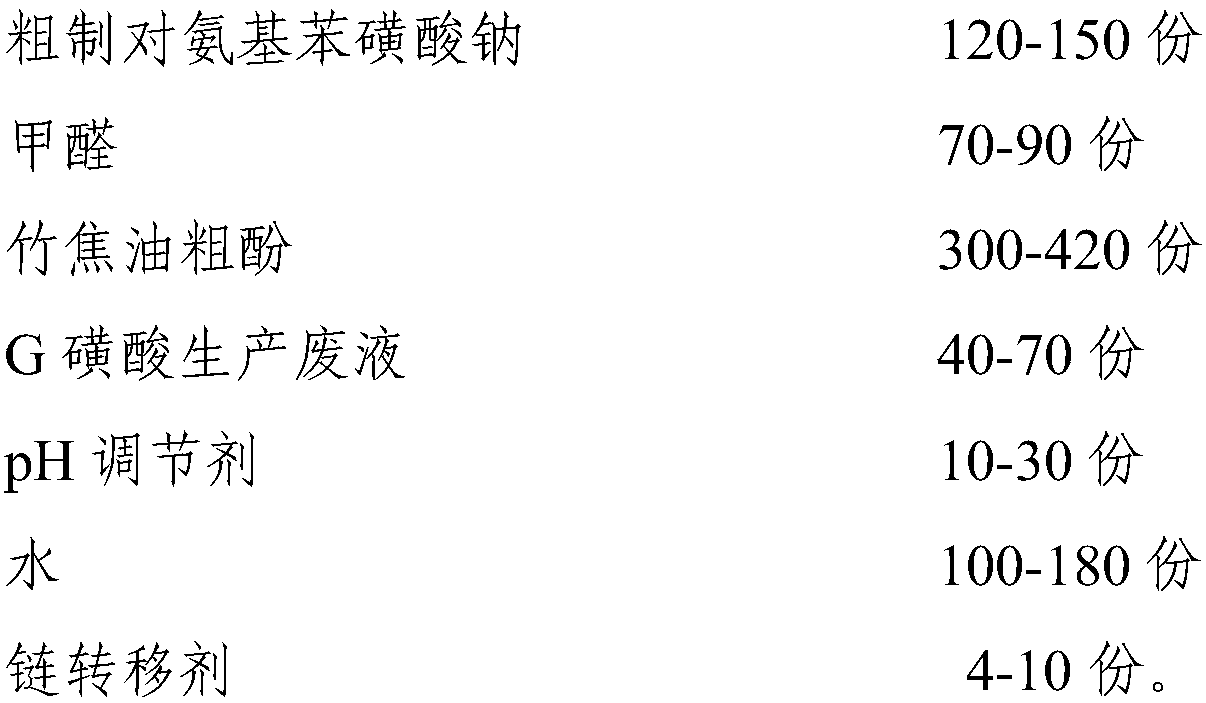

preparation example Construction

[0029] Its preparation method comprises the following steps:

[0030] (1) Dissolving and filtering: add water to the reactor, then add crude sodium sulfanilate and bamboo tar crude phenol respectively, raise the temperature of the reactor to 80-85°C, stir for not less than 1 hour, cool, Filter to remove the solid slag, keep the filtrate for later use;

[0031] (2) Addition: Slowly add a pH regulator to the filtrate obtained in step (1) to adjust the pH of the solution to 8-9;

[0032] (3) Polycondensation: heat the solution to 90-95°C, slowly add formaldehyde solution to it, so that the formaldehyde will be dripped within 1.5-2 hours, and keep warm for no less than 2 hours;

[0033] (4) Copolymerization: Add G sulfonic acid production waste liquid to the solution, keep the solution temperature between 75-85°C for 1-2 hours, adjust the solid content with water, and obtain the finished product.

[0034] When in use, the water reducer can be mixed into the cement at 1.4wt% of t...

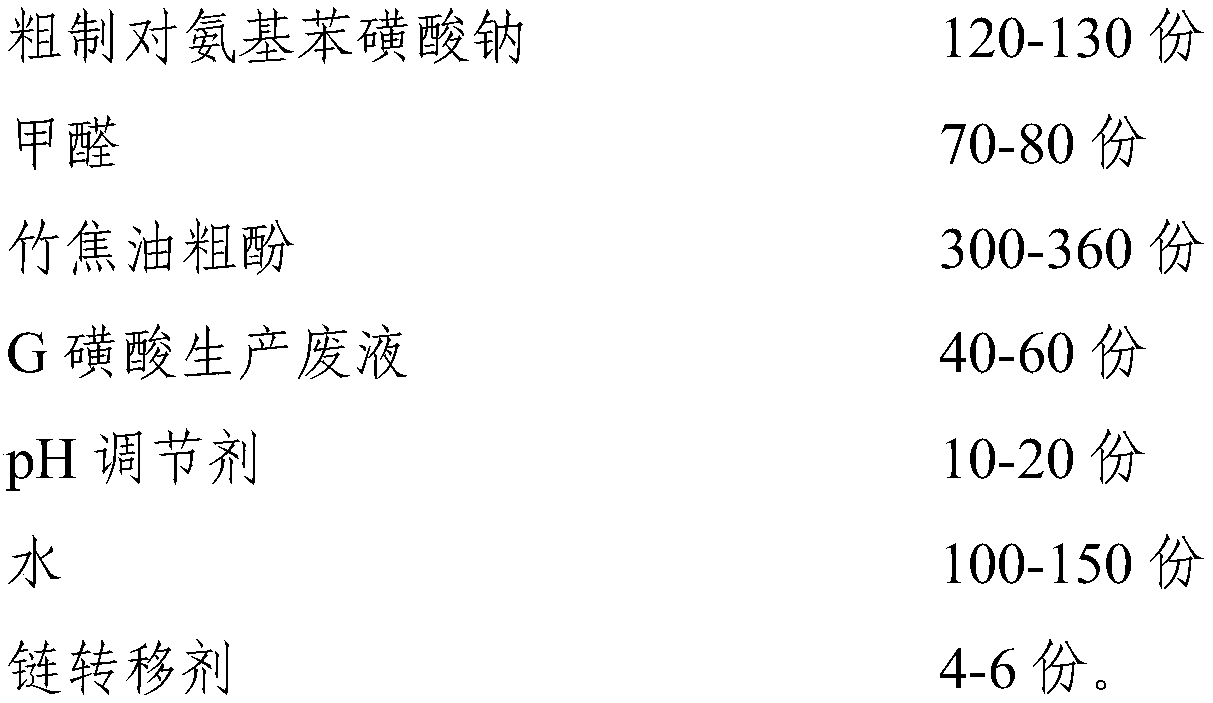

Embodiment 2

[0036] A kind of G sulfonic acid production waste liquid modified sulfamic acid series high-efficiency water reducer, including the following raw materials in parts by weight:

[0037]

[0038] Its preparation method is with embodiment 1.

[0039] When in use, the water reducing agent can be mixed into the cement at 1.1wt% of the weight of the cement.

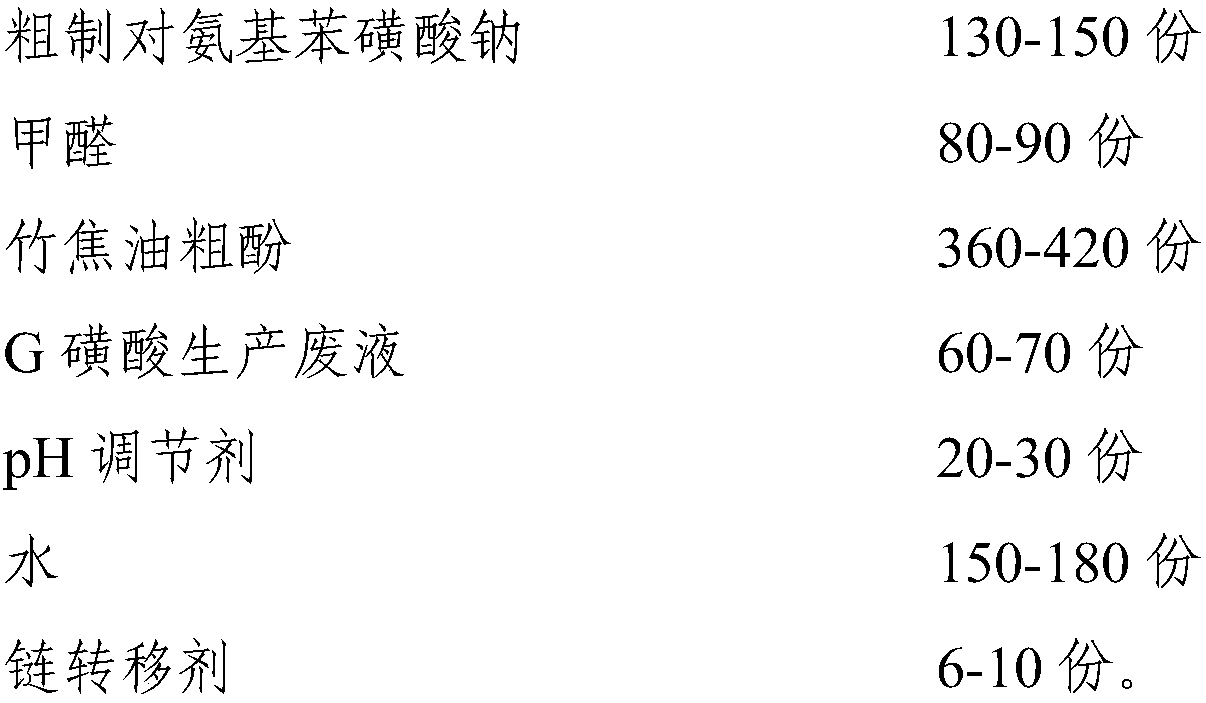

Embodiment 3

[0041] A kind of G sulfonic acid production waste liquid modified sulfamic acid series high-efficiency water reducer, including the following raw materials in parts by weight:

[0042]

[0043] Its preparation method is with embodiment 1.

[0044] When in use, the water reducing agent can be mixed into the cement at 1.2wt% of the weight of the cement.

[0045] When in use, the water reducing agent can be mixed into the cement at 1.5wt% of the weight of the cement.

[0046] The performance data of the water reducer prepared in Examples 1-4 are shown in the following table:

[0047]

[0048] As can be seen from the above table, compared with the test standard of the national standard "Concrete Admixture", the water-reducing agent prepared in Examples 1-4 has a higher water-reducing rate, a lower air content, and a lower 28d shrinkage ratio. Concrete has high compressive strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com