Matrix-type electroplating production line

An electroplating production line and geared motor technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of small floor space, difficulty in shortening the running time, and inability to walk left and right, so as to reduce the floor space and shorten the production cycle, the effect of improving exercise flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

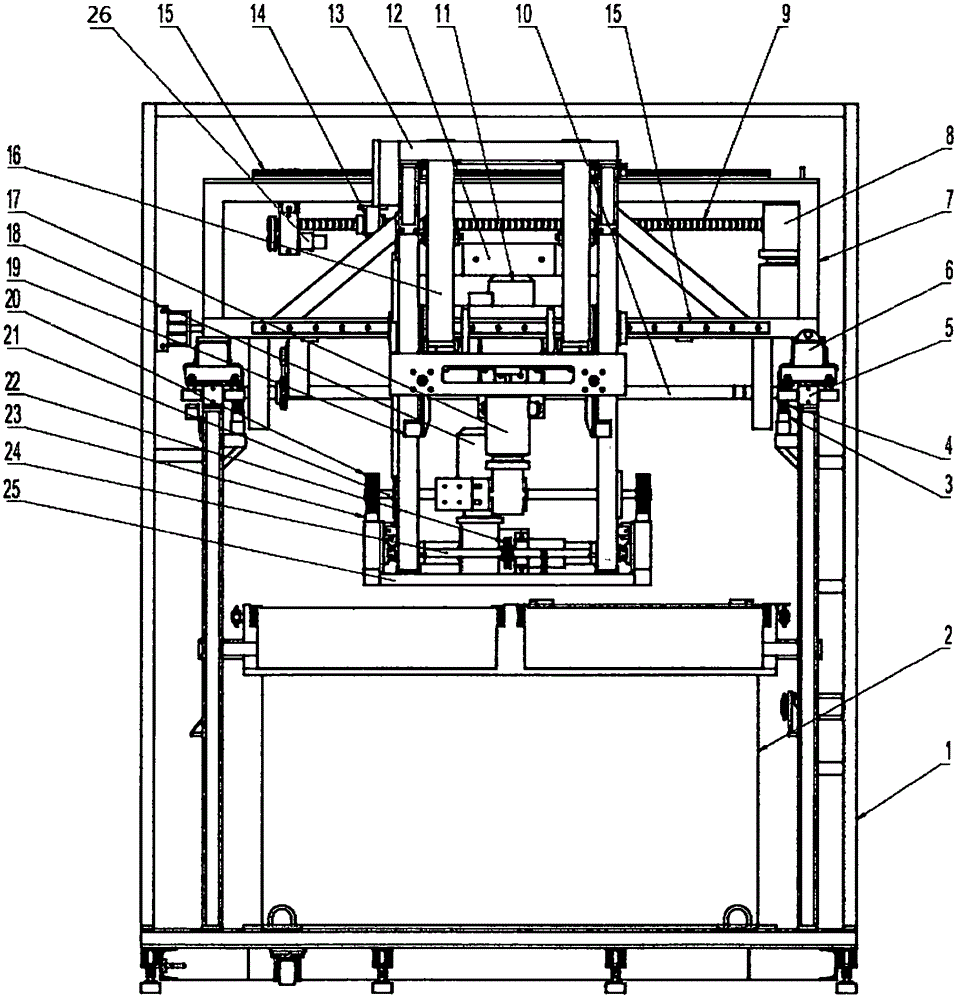

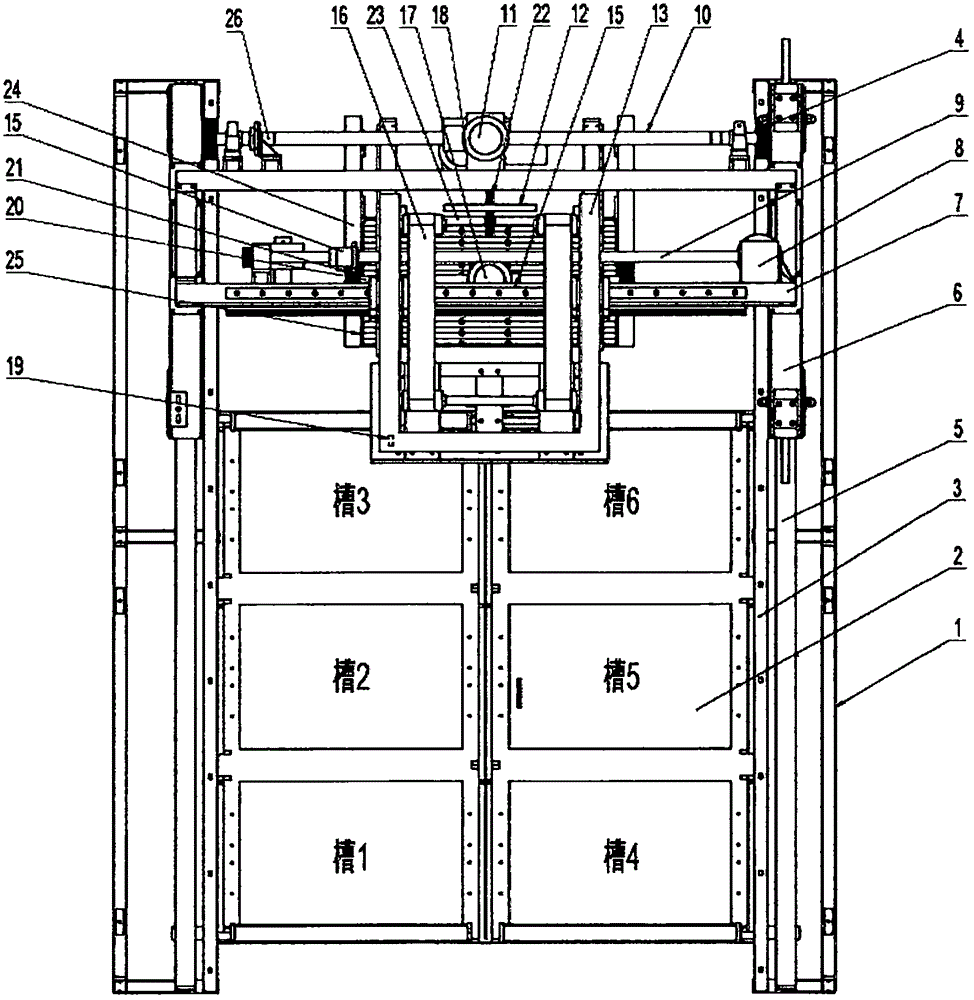

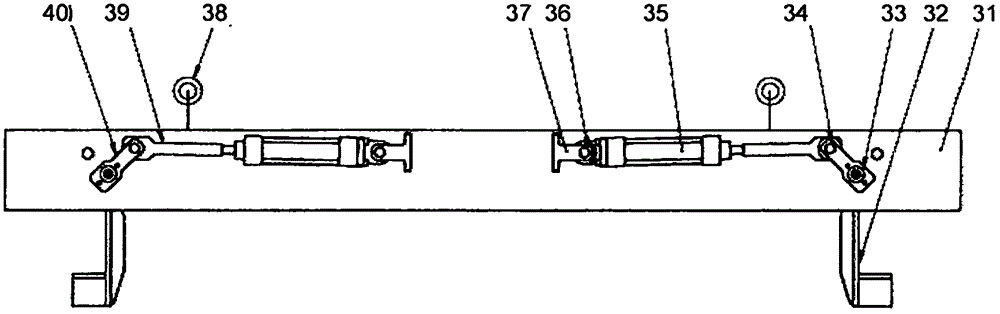

[0038] see figure 1 with figure 2 ,in figure 1 It is a schematic diagram of a matrix electroplating production line and a driving structure according to an embodiment of the present invention, figure 2 yes figure 1 The top view of the matrix electroplating production line and the crane structure shown.

[0039] In this embodiment, a matrix type electroplating production line comprises: a matrix type driving 7; a plurality of tank bodies 2, the tank body 2 adopts a matrix arrangement, and double rows of grooves are arranged side by side (in this embodiment, double rows of grooves are used) Body arrangement, but not limited thereto, can also be set to more rows of tanks arranged side by side, and the number of tanks in each row can be the same or different); the frame 1 that plays an integral su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com