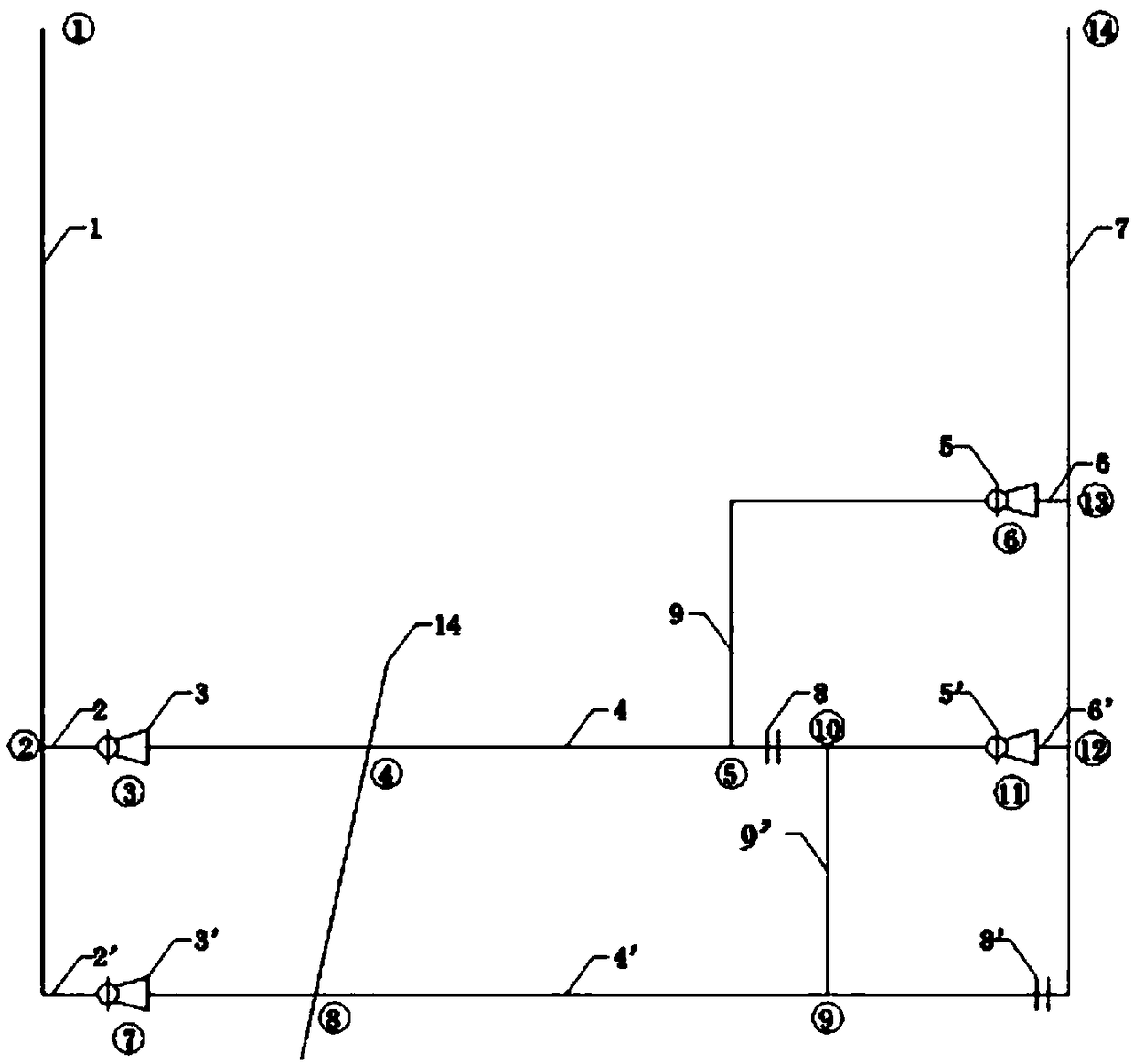

A test method for anti-wind test of multi-stage machine station ventilation system in underground metal mine

A test method and ventilation system technology are applied in the field of anti-wind test system for underground metal mines, which can solve the problems of poor operability of metal mines, and achieve clear, reliable and reliable anti-wind effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

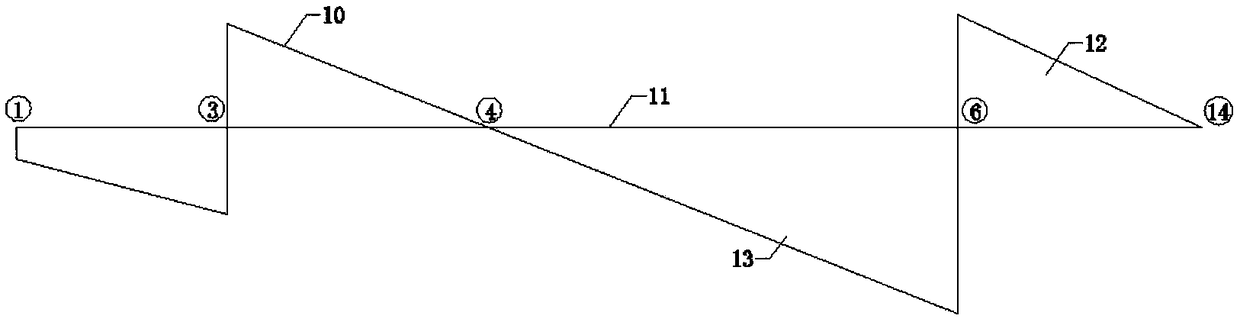

Embodiment 2

[0057] Embodiment 2: When the catastrophe occurs on the air return side of the air path A, the upper and middle horizontal damper 8 is opened, and the upper and middle inlet fan 3, the lower and middle inlet fan 3' and the upper and middle return fan 5 are used for normal ventilation, and the lower and middle section Return air fan 5' closing mode.

[0058] The specific operation implementation steps are:

[0059] (1) with embodiment 1;

[0060] (2) Check the upper and middle inlet fan 3, the lower and middle inlet fan 3', the upper and middle return fan 5, and the lower and middle return fan 5', and set the fan remote centralized monitoring platform to the remote control state;

[0061] (3) Turn off the lower and middle section return air fan 5' on the fan remote centralized monitoring platform;

[0062] (4) Under the new ventilation state, carry out the detection of the operating conditions of the ventilation system, detect the wind speed, air volume and wind direction of ...

Embodiment 3

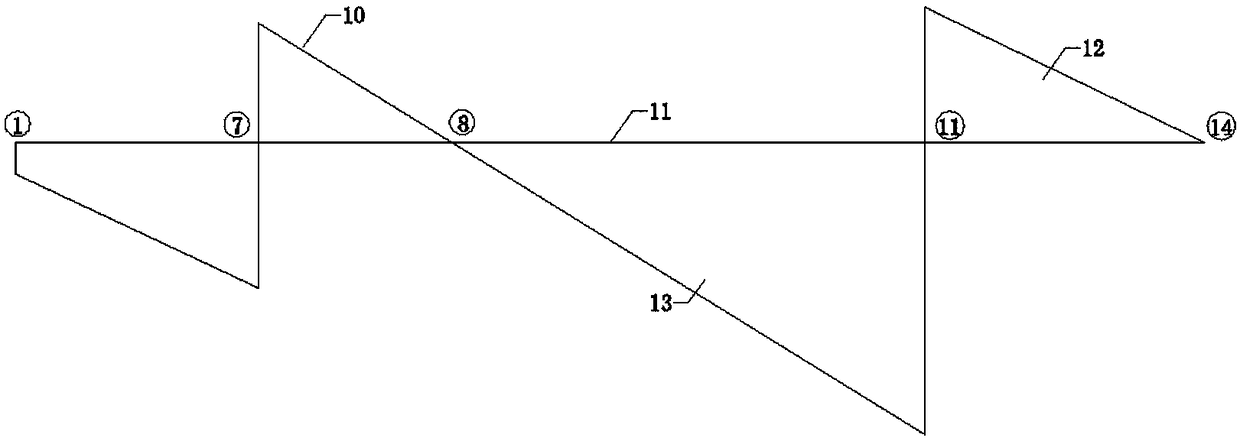

[0064] Embodiment 3: When the catastrophe occurs on the air return side of the air path B, open the upper and middle horizontal damper (8), and use the upper and middle inlet fan (3), the lower and middle inlet fan (3') and the lower and middle return fan (5') normal ventilation, and the upper and middle return air fan (5) is closed.

[0065] The specific operation implementation steps are:

[0066] (1) with embodiment 2;

[0067] (2) with embodiment 2;

[0068] (3) Close the upper and middle return air fan 5 on the fan remote centralized monitoring platform;

[0069] (4) Under the new ventilation state, the operating conditions of the ventilation system are detected, the wind speed, air volume and wind direction of the upper and middle air lane 4 and the lower middle air lane 4' are detected, and the return air volume of the lower and middle return fan 5' is detected;

[0070] 5) After step (4) is completed, the anti-wind test is over; and then turn on the upper and middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com