Jet pump test bench for heating

A technology of jet pump and test bench, which is applied in the field of jet pump for heat supply and jet pump heating system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

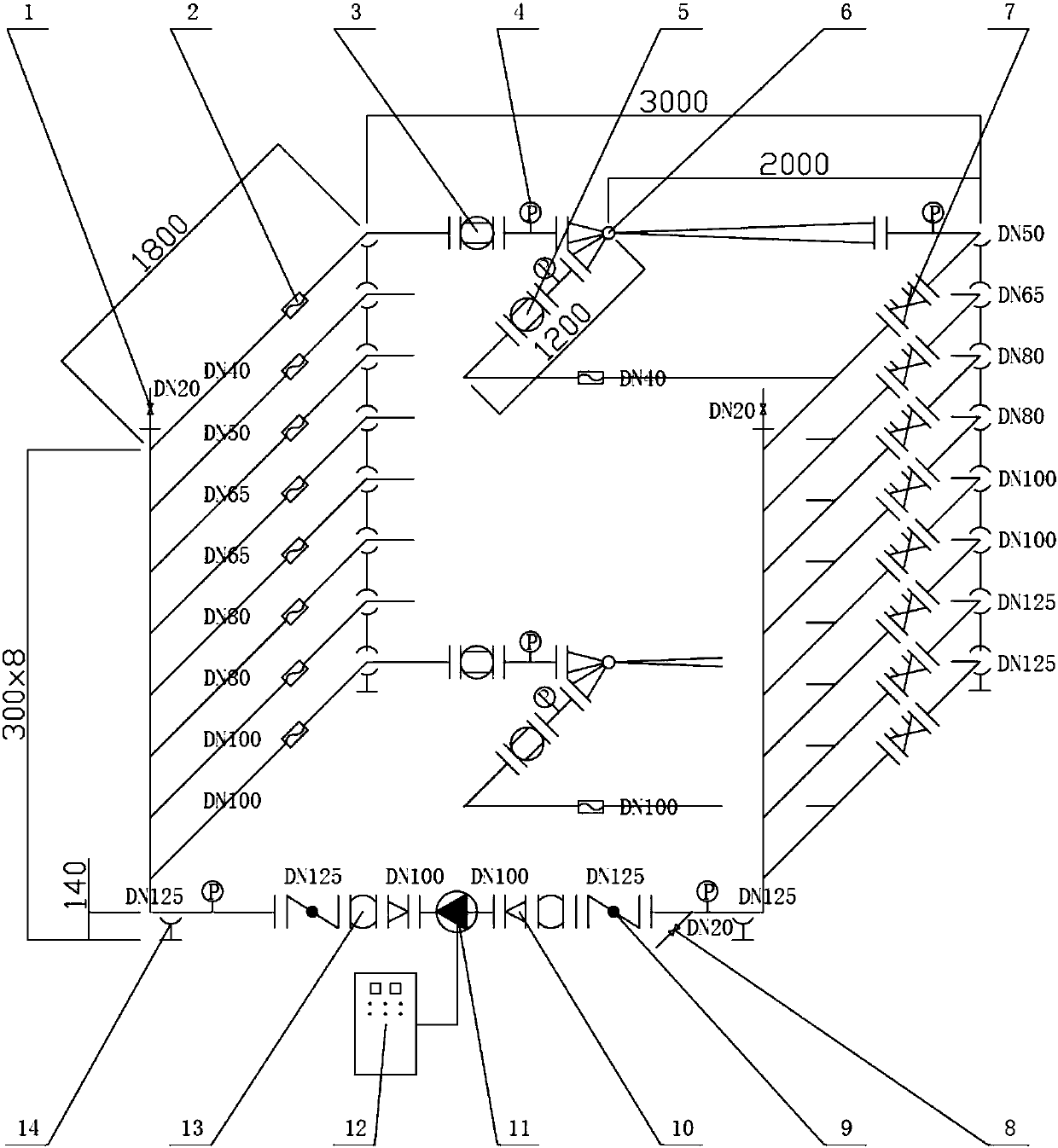

[0012] A jet pump test bench for heating, including an exhaust valve, an ultrasonic flowmeter, a jet ball valve, a digital pressure gauge, an injection ball valve, a jet pump for heating, a regulating balance valve, a water replenishing valve, a butterfly valve, a reducing pipe, and a circulation Pumps, frequency conversion control cabinets, flexible connecting pipes, brackets, etc.

[0013] Multiple jet pumps for heating are installed in parallel, with different models; each jet pump for heating has a jet ball valve, an injection ball valve, and a regulating balance valve connected to it, and its operating pressure can be directly controlled by the digital pressure gauge in between. Readout: The flow through the injection ball valve and injection ball valve of each heating injection pump can be directly measured by the ultrasonic flowmeter on it.

[0014] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com