A self-adjusting human-driven drum brake

A drum brake, human-driven technology, applied in the direction of mechanically driven drum brakes, slack adjusters, brake actuators, etc., can solve the problem that the brake gap cannot be adjusted automatically, and achieves easy assembly, improved service life, and no debugging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

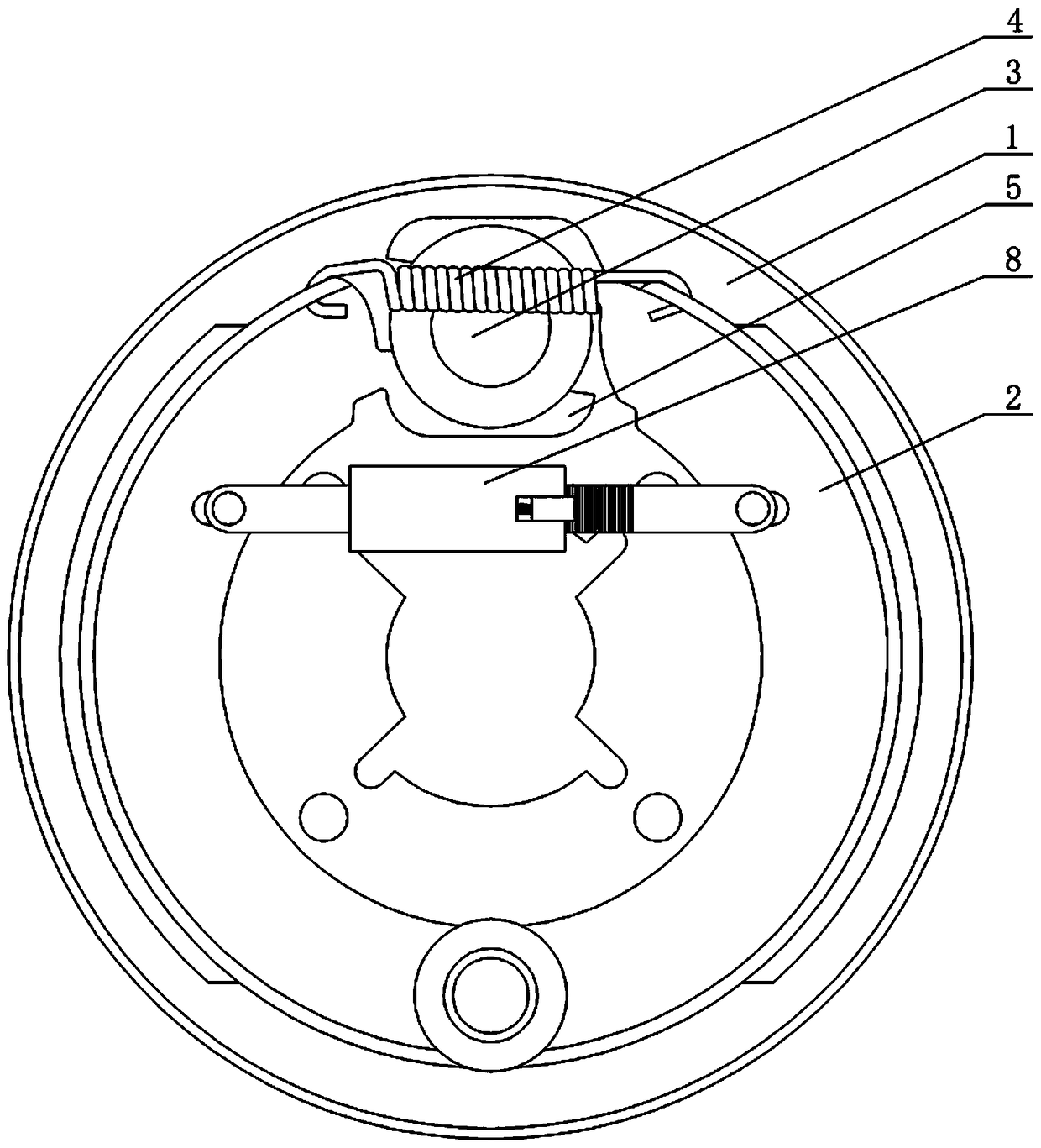

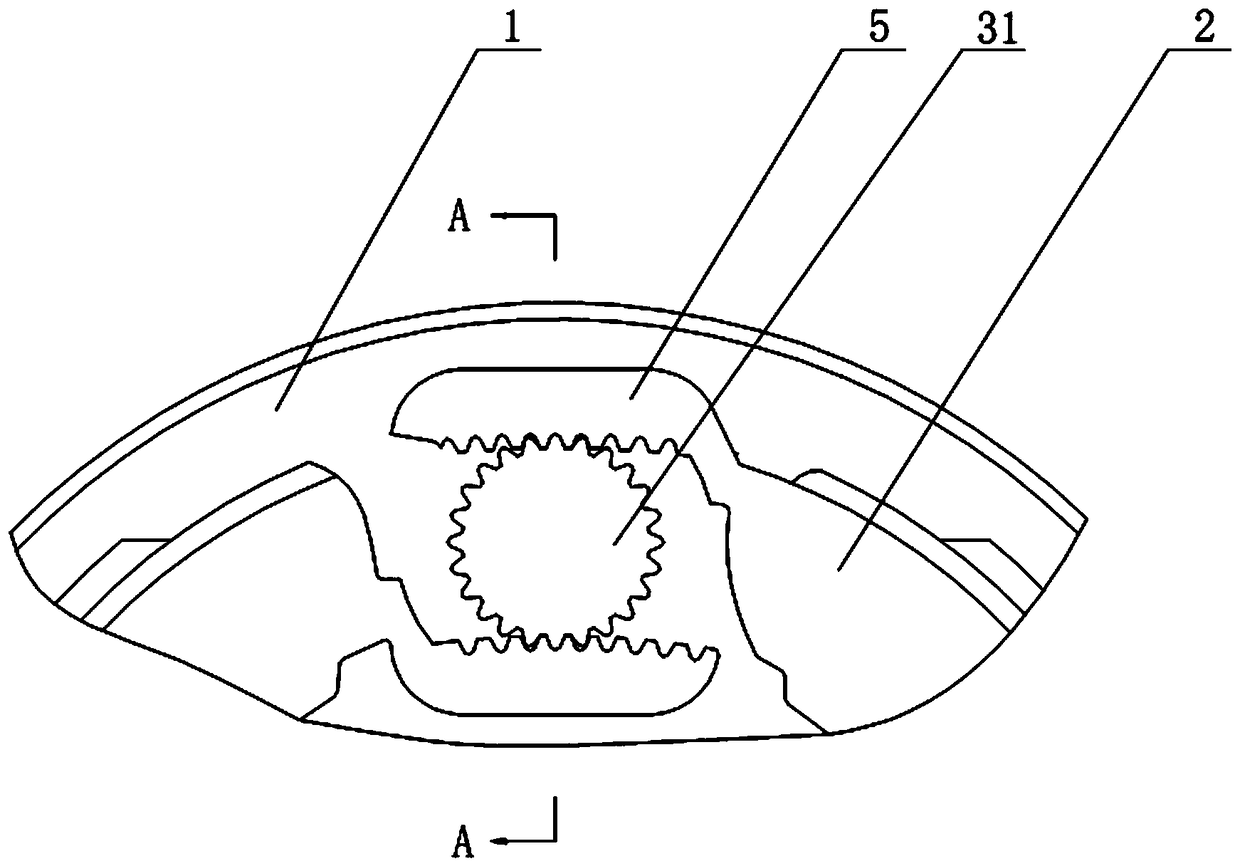

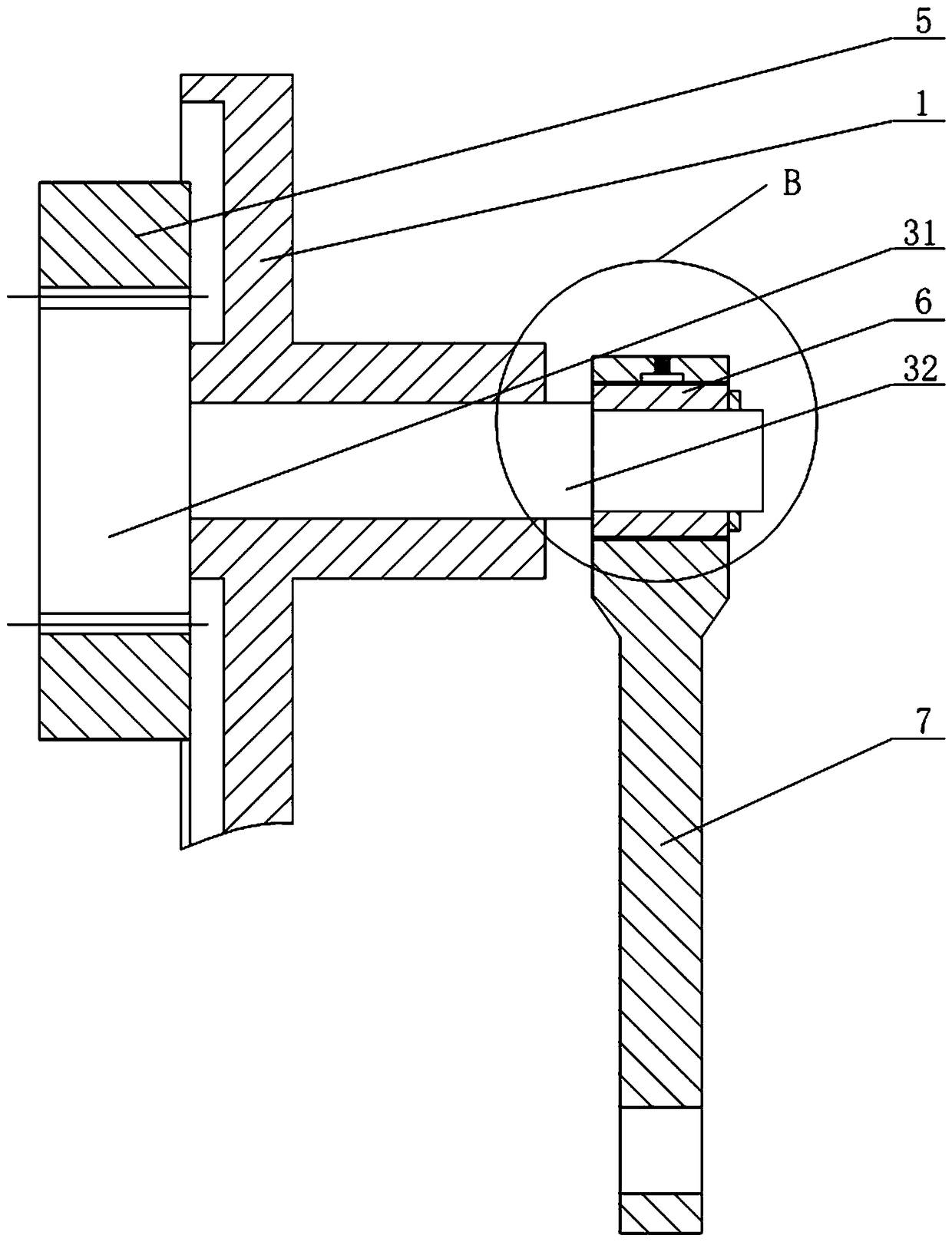

[0020] Depend on Figure 1 to Figure 6 As shown, a self-adjusting human-driven drum brake includes a brake base plate 1, two symmetrical brake shoes 2 and a brake shoe actuator 3, and one end of the two brake shoes 2 is hinged on the On the brake base plate 1, a return spring 4 is provided between the two brake shoes 2, and the other ends of the two brake shoes 2 are respectively provided with corresponding racks 5 up and down. The brake shoe actuating device 3 includes a gear 31, a gear shaft 32 and a swing arm 7, the gear shaft 32 is installed through the brake base plate 1, the gear 31 is placed between the racks 5 on the two brake shoes 2 and meshed with the rack 5, The passing end of the gear shaft 32 is connected with the swing arm 7 through the one-way torque transmission mechanism 6, and the torque transmission direction of the one-way torque transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com