Vacuum pulse drying machine

A vacuum pulse and drying machine technology, which is applied in the direction of local stirring dryers, static material dryers, dryers, etc., can solve the problems of accelerating the drying rate of materials, uneven heating of materials, and difficult discharge of solvents, etc., to achieve convenience Filling operation, quick overflow, effective energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

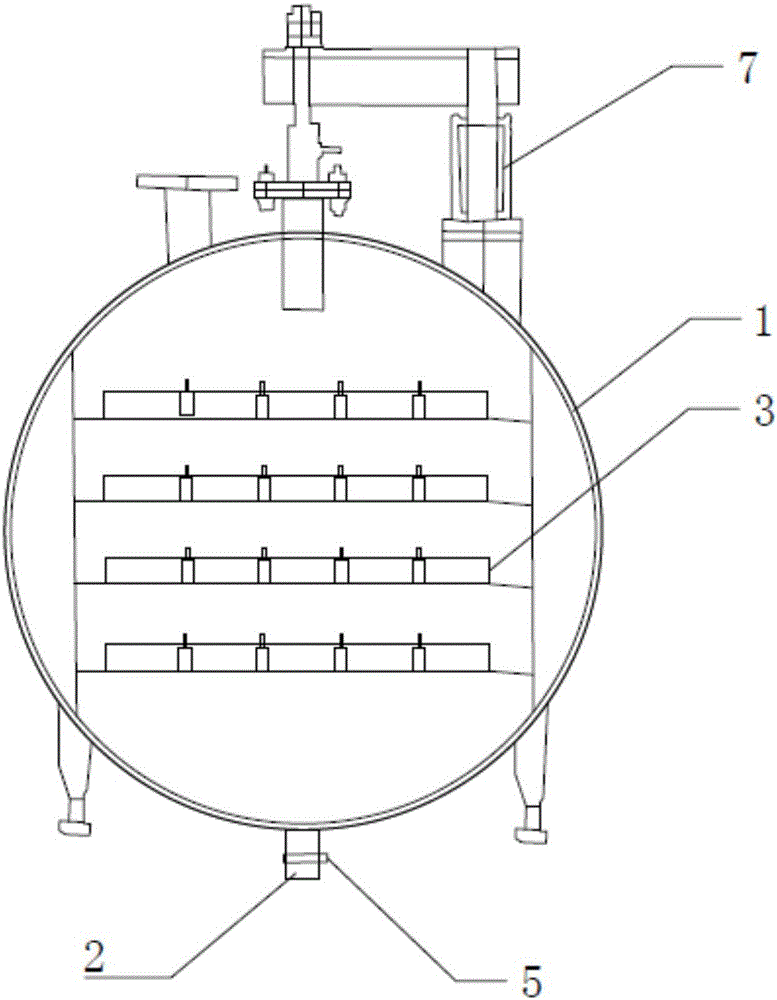

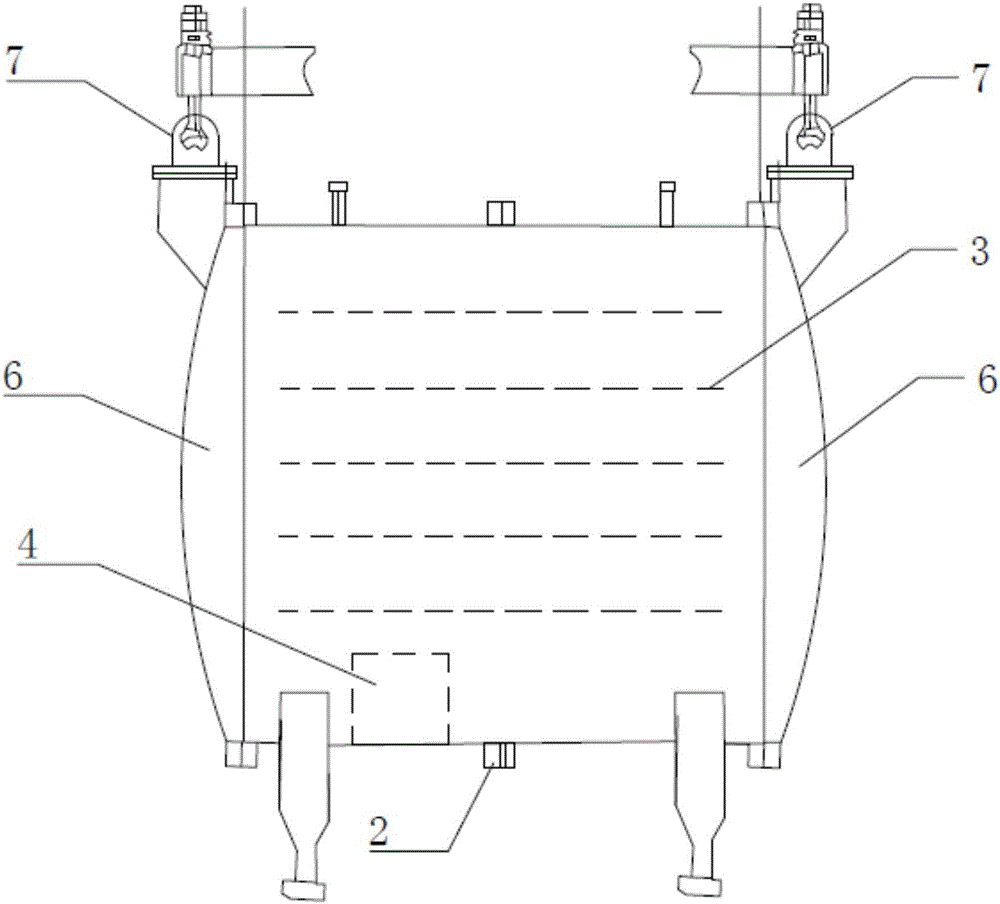

[0015] Such as figure 1 , figure 2 As shown, a vacuum pulse dryer includes a drying box 1 and a vacuum device, the bottom of the drying box 1 is provided with a drain pipe 2, and the inside of the drying box 1 is provided with a multilayer longitudinally arranged plane heating plate 3. The drying box 1 is provided with a vacuum degree measuring device 4, the vacuum degree measuring device 4 is electrically connected to the PLC controller, and the vacuum pumping device is also electrically connected to the PLC controller.

[0016] As a preferred embodiment of the present invention, the drying box 1 is cylindrical.

[0017] As a preferred embodiment of the present invention, the drain pipe 2 is provided with a ball valve 5 .

[0018] As a preferred embodiment of the present invention, the front and rear sides of the drying box 1 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com