Three-phase multiple extrusion graphite electrode distribution ferroalloy furnace power transmission smelting method and system

A technology of graphite electrode and smelting method, which is applied in the direction of electric furnace heating, furnace, furnace components, etc., can solve the problems of complex process technology and high price, and achieve the effects of improving economic benefits, high flexural strength, and increasing the cross-section of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

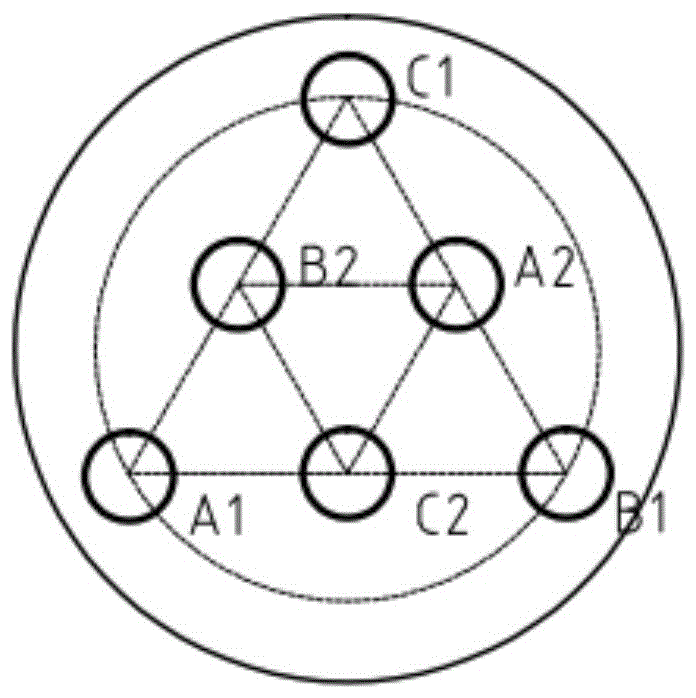

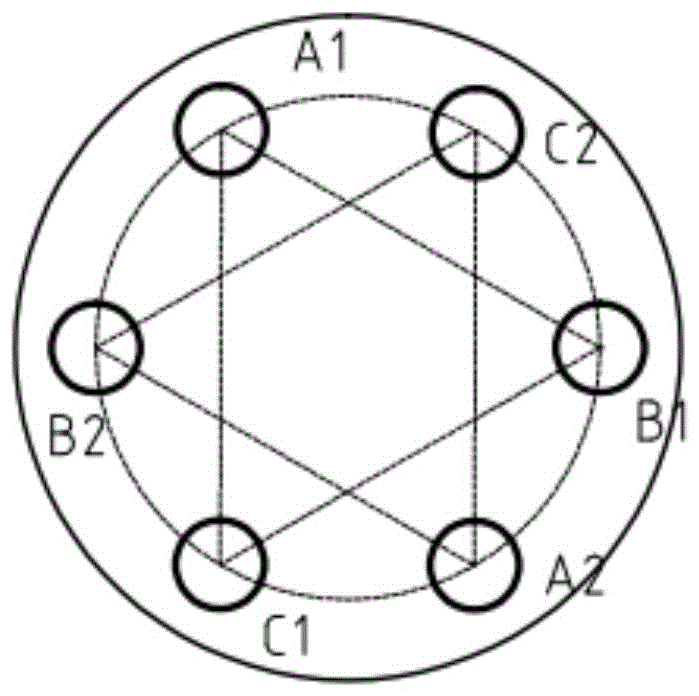

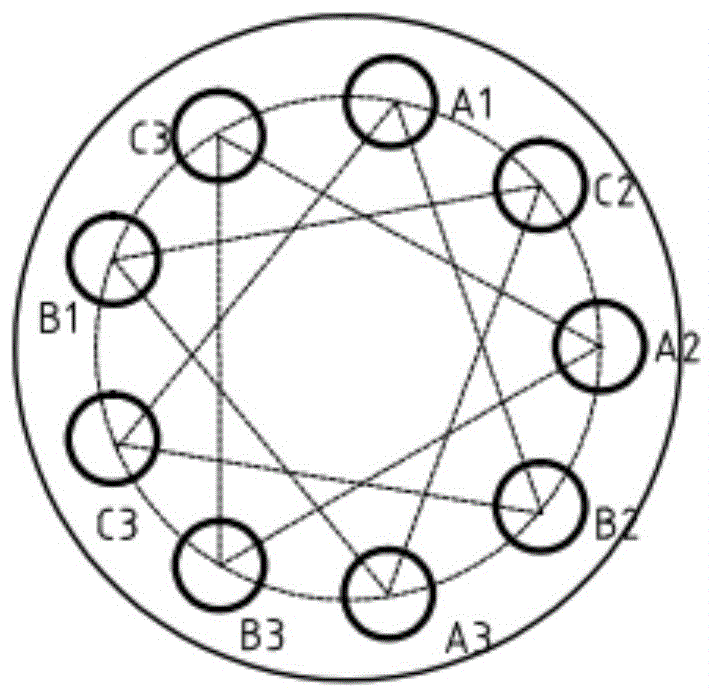

[0030] Example: see figure 1 — Figure 5 , in the figure, A, B, and C represent the three phases of the transformer, A1-A4 represent different graphite electrodes of A phase, B1-B4 represent different graphite electrodes of B phase, and C1-C4 represent different graphite electrodes of C phase.

[0031] Three-phase multi-extruded graphite electrode layout ferroalloy furnace power transmission smelting method and system, and its technical scheme is:

[0032] a. Divide each phase of the three-phase terminals on the secondary side of the transformer into at least two electrode terminals connected in parallel, and each electrode terminal is connected to a high-quality extruded graphite electrode (referred to as graphite electrode); or, The three-phase terminals on the secondary side of the transformer with the same polarity are divided into at least two groups, and each group is connected to a column of high-quality extruded graphite electrodes;

[0033] b. Select the diameter an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com