Observing device and method for filler changing process at different water flow velocities

A technology of water flow velocity and observation device, which is applied in the direction of measuring device, flow characteristics, fluid dynamics test, etc., can solve the problems of waiting for maturity, lower reliability of test results, and difficulty in real-time observation of filling changes, so as to facilitate the filling work , the effect of improving efficiency and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

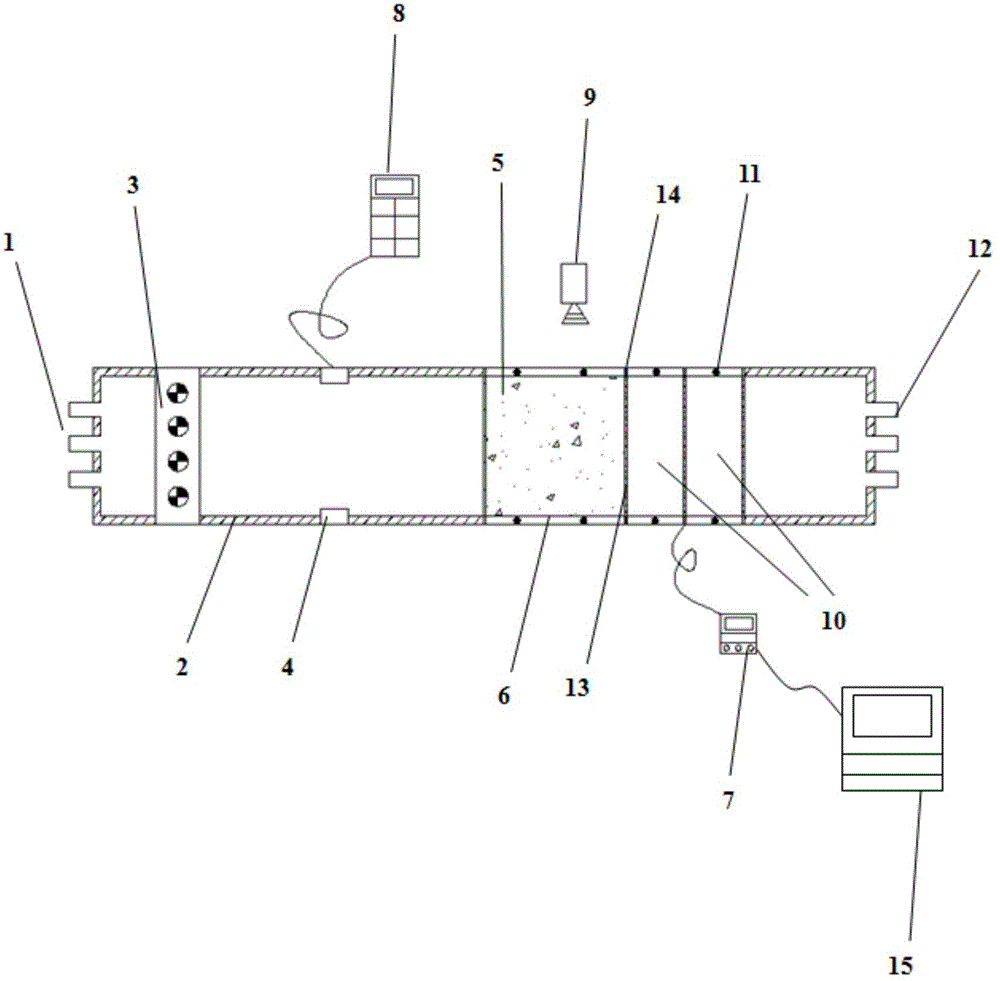

[0031] Such as figure 1 , figure 2 As shown, the experimental device for real-time observation of filling material migration under variable flow rate, including water inlet 1; test water pipe 2; speed adjustment device 3; flow meter 4; material area 5; sealing rubber pad 6; flow sensor receiver Device 7; flow rate display 8; high-speed camera 9; tempered glass top plate 10; fastening bolt 11; water outlet 12; screen 13; card slot 14; computer system 15;

[0032] One end of the test water pipe 2 is a water inlet 1, and the other end is a water outlet 12. A water velocity regulating device 3 is installed at the water inlet 1 of the test water pipe, and a flow meter 4 is provided on the inner wall of the test water pipe 2;

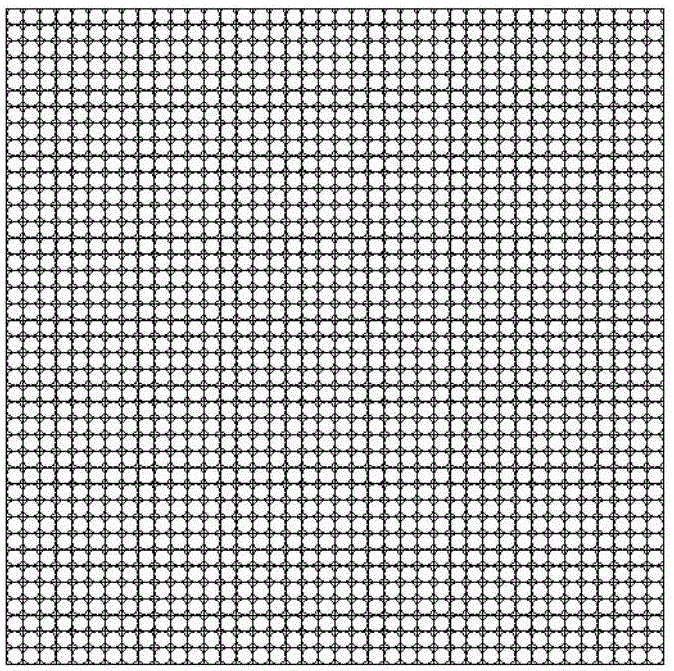

[0033] A section of packing area 5 is provided in the test water pipe 2. Along the direction of water flow, a water baffle is provided in front of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com