Sequencing batch type dry anaerobic digestion device of kitchen wastes

A dry anaerobic and kitchen waste technology, applied in the field of waste recycling technology and biomass energy, can solve the problems of poor control performance and easy acidification in the anaerobic process, achieve convenient control, improve operability and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

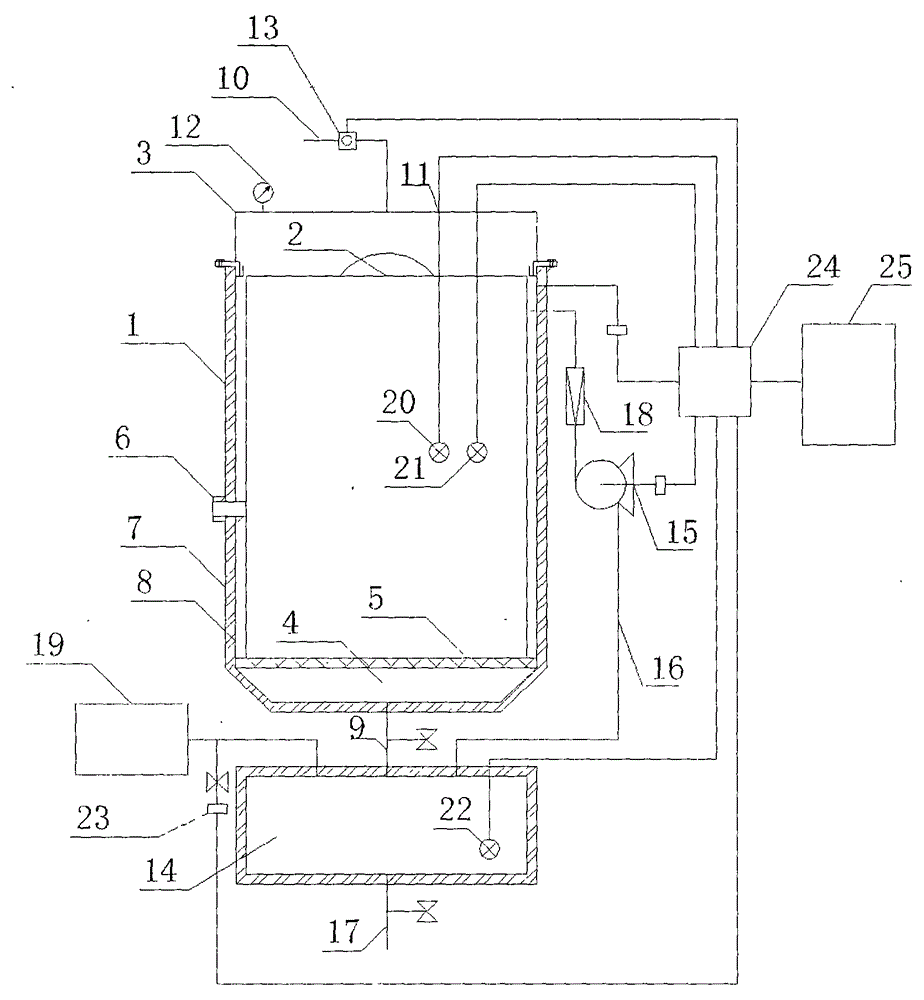

[0032] See figure 1 .

[0033] A sequential batch dry anaerobic digestion device for food waste, comprising a dry anaerobic digestion reactor (1), an inlet and outlet container (2), a sealing cover (3), a biogas slurry collection chamber (4), and a perforated plate (5), biogas residue sampling port (6), insulation layer (7), heating layer (8), biogas slurry discharge pipe (9), biogas outlet (10), sensor interface (11), safety valve (12) , gas flow meter (13); the biogas slurry return system consists of a biogas slurry storage tank (14), a biogas slurry return pump (15), a biogas slurry return pipeline (16), a biogas slurry sampling port (17), a liquid flow meter ( 18), alkalinity dosing device (19), insulation layer (7), heating layer (8); monitoring control system is made up of temperature sensor (20), pH sensor (22), ORP sensor (21), relay (23 ), PLC controller (24), PLC automatic control system and on-site touch screen (25), etc.

[0034] The dry-type anaerobic digestion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com