Testing device and method for smooth level in industrial product logistic process

A technology for testing devices and industrial products, applied in the field of intelligent sensing, which can solve problems such as inaccurateness, coarse-grained methods, and easy loss, etc., and achieve the effects of accurate data analysis methods, multiple applicable scenarios, and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

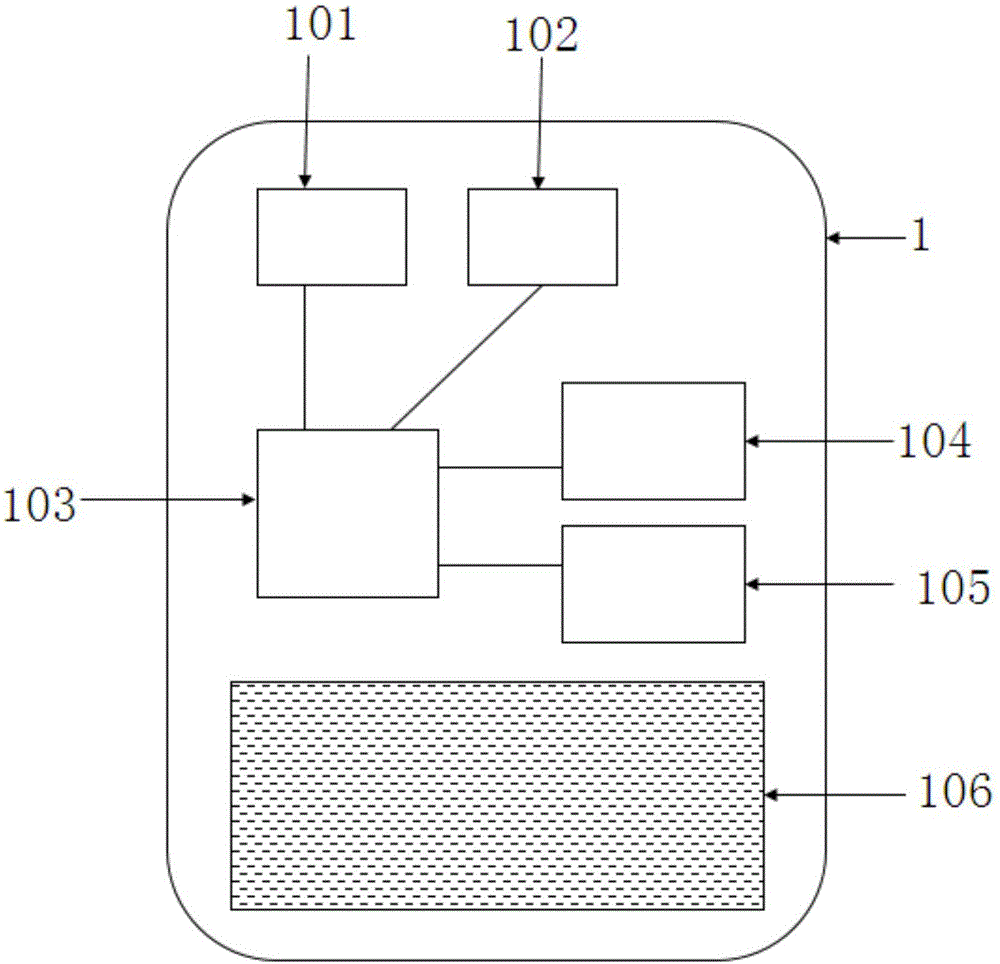

[0044] refer to figure 1As shown, this embodiment discloses a test device aimed at the level of stability in the logistics process of industrial products. Its structure mainly includes: a casing 1, and the inside of the casing 1 is provided with a 3-axis acceleration sensor 101 and a 3-axis angular velocity sensor 102. , a processor 103, a data storage module 104, a data export module 105, a battery 106, the 3-axis acceleration sensor 101 and the 3-axis angular velocity sensor 102 obtain sensing signal data in real time, and transmit to the processor 103, the processing The device 103 reads the data of the 3-axis acceleration sensor 101 and the 3-axis angular velocity sensor 102 and processes them to obtain the acceleration and angular velocity of the device. After calculating the acceleration and angular velocity and calculating the space attitude, the transportation stability coefficient S is obtained, and the transportation stability coefficient S is obtained. Stored in the...

Embodiment 2

[0059] Embodiment 2 is based on the test device of Embodiment 1. Before the test, set up the equipment. In this embodiment, the acceleration sensor and the angular velocity sensor select a 3-axis chip that outputs data correctly, and the sampling rate is at least 50 Hz. The data export module is Bluetooth 4.0 module.

[0060] A test method for the smooth level in the logistics process of industrial products is disclosed, comprising the following steps:

[0061] S 101 places the test device in the cargo, and starts the test device through the bluetooth device (mobile phone);

[0062] S102 The test device enters the working state after receiving the start working order;

[0063] The S 103 test device continuously reads the resin of acceleration and angular velocity, and calculates the space attitude of the device in real time. Through the space attitude and the value of the acceleration sensor, the value of the acceleration of the test device in the earth coordinate system is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com