Automatic vending machine with XY lifting goods receiving system

A vending machine and lifting system technology, applied in the direction of handling coins or valuable banknotes, coin-free or similar appliances, and coin-operated equipment for distributing discrete items, can solve the problem of reducing the use efficiency of the box and adapting the whole machine Poor performance, many movement mechanisms, etc., to achieve the effect of improving use efficiency, increasing inventory, and improving anti-theft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

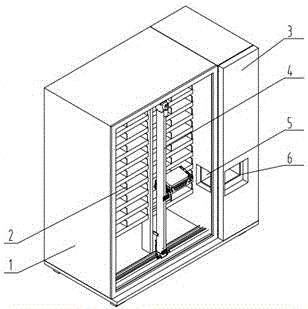

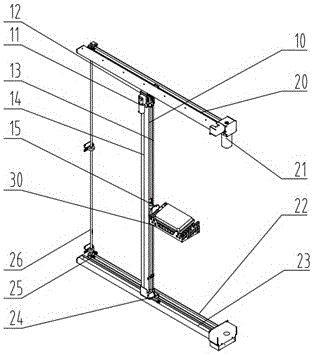

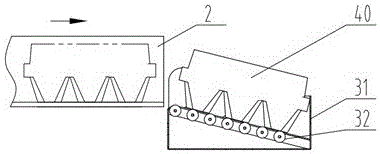

[0030] Such as figure 1 , figure 2 , image 3 As shown, a pallet cargo lane 2 and an XY lifting and receiving system 4 are arranged in the main cabinet 1, and the XY lifting and receiving system arrangement 4 is arranged at the front end of the pallet cargo lane 2 in the shipping direction, between the main cabinet 1 and the auxiliary cabinet 3 There is a delivery port 5, and a pick-up port 6 is arranged outside the auxiliary cabinet 3; the XY lifting and receiving system 4 is composed of a Y-direction lifting system 10, an X-direction operating system 20 and a receiving box 30, and the Y-direction lifting system 10 is up and down. The two ends are installed on the X-direction slider 24 arranged up and down in the X-direction operating system 20, and the receiving box 30 is installed on the Y-direction slider in the Y-direction lifting system 10; the Y-direction lifting system 10 is controlled by the Y-direction motor 11 , Y-direction gear 12, Y-direction timing belt 13, Y-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com