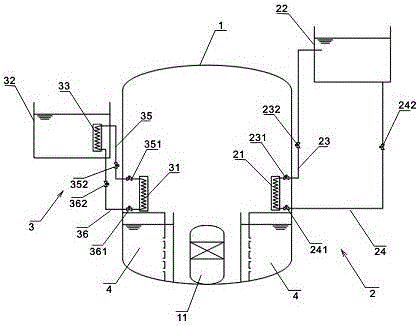

Novel passive safety shell energy control system

A passive containment and energy control technology, applied in the field of nuclear power, can solve the problems of very large containment structure size, high space requirements, and increased construction costs, so as to ensure diversity and redundancy and avoid system failure , the effect of enhancing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0033] In other embodiments, the novel passive containment energy control system of the present invention can be applied to pressurized water reactor nuclear power plants of 3-2 million kilowatt (electric power) level. The passive containment energy control system has less requirements on the structure, size and material of the containment (such as the reactor compartment system design applicable to marine nuclear power platforms). After design basis accidents and beyond design basis accidents (including severe accidents) in the reactor, neither active systems nor operator intervention are required to ensure the long-term continuous discharge of heat in the containment and keep the reactor in a safe state. In addition, the heat exchange capacity is not dependent on the formation of uncontrollable water film, and there is no need to set up a water tank that can provide cooling water for submerging the containment, and there is no need to set up a pool for containing cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com