Flexible terahertz metamaterial wave absorber and manufacturing method thereof

A manufacturing method and wave absorber technology, applied in the terahertz field, can solve the problems of metamaterial redesign, cumbersome preparation process, and differences in process parameters, and achieve the effects of reducing the number of photolithography times, simplifying the manufacturing method, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

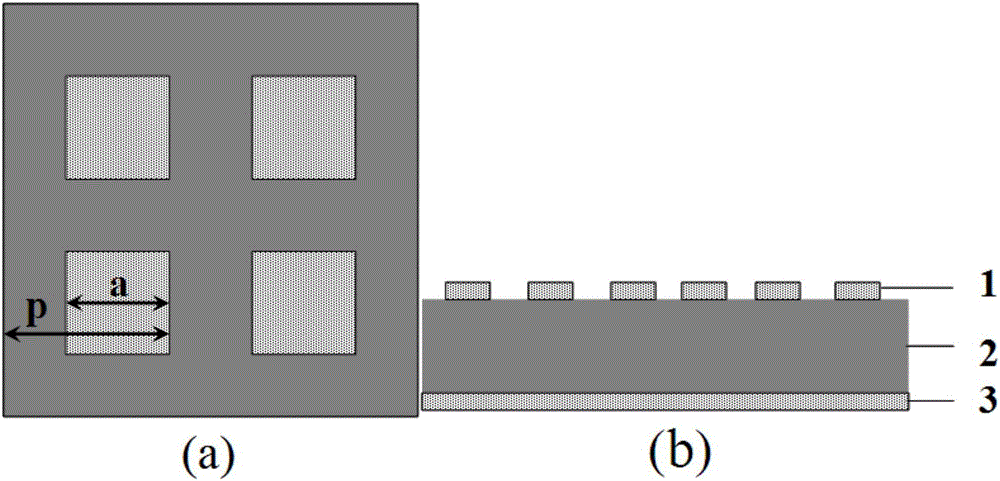

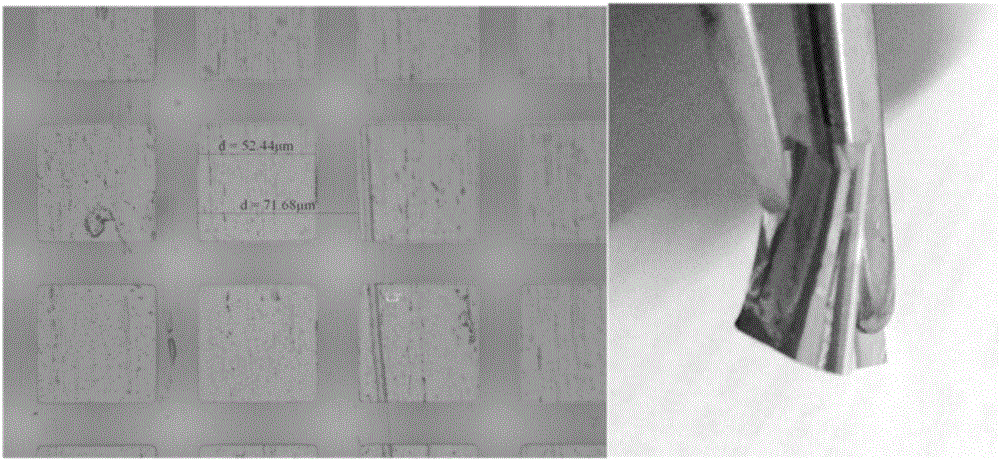

[0043] figure 1 It is a schematic diagram of the flexible terahertz metamaterial wave absorber of the present embodiment; figure 2 It is the physical picture of the flexible terahertz metamaterial wave absorber of this embodiment, a is an optical microscope photo, and b is a photo when it is bent; as shown in the figure, the wave absorber includes a layer of patterned Metal film 1, one layer of flexible dielectric film 2 and one layer of continuous metal film 3; the metal figure of the patterned metal film presents a square periodic structure figure, P is the square unit periodic side length of 72 μm, and a is The side length of the square shape is 52 μm.

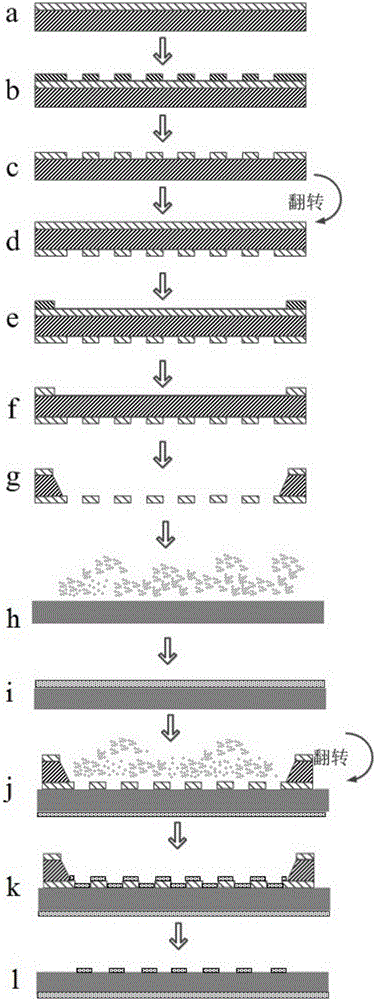

[0044] Such as image 3 As shown, the manufacturing method of the flexible terahertz meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com